Method for purifying hydrophilic mannosylerythritol lipids

A purification method, sugar erythrose technology, applied in chemical instruments and methods, organic chemistry, sugar derivatives, etc., can solve the problems of high cost, inability to meet the industrial production of MELs, waste of products and organic solvents, etc., and achieve efficient and rapid separation Effect of purification, promotion of industrial production and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

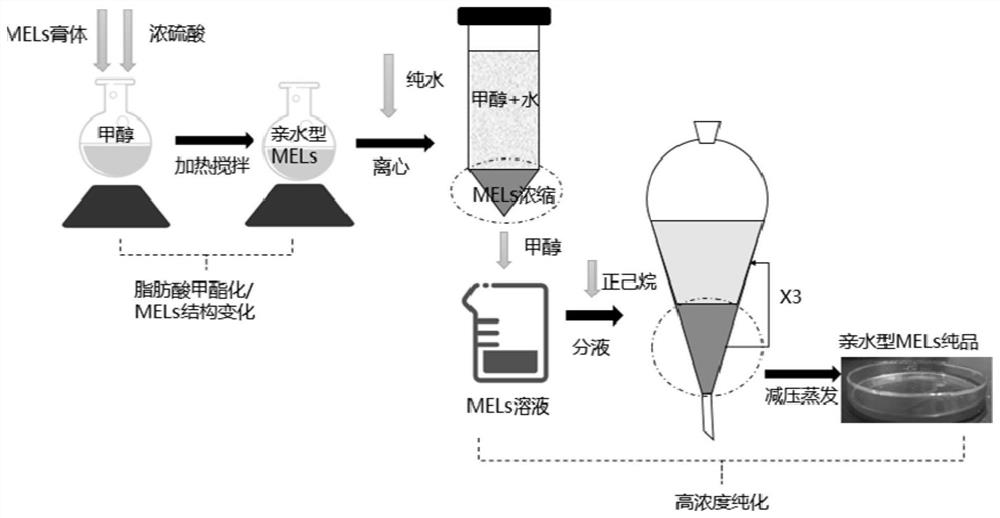

Method used

Image

Examples

Embodiment 1

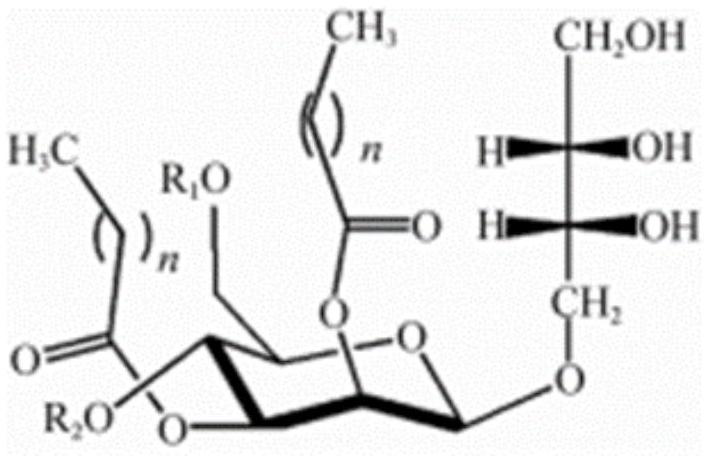

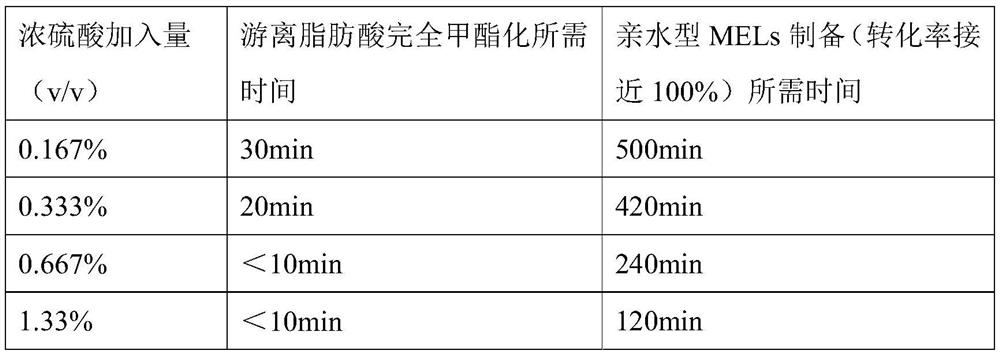

[0025] Take 2.5g of paste-like MELs crude product, dissolve it in 30ml of methanol, add 50-400μL of concentrated sulfuric acid until the volume fraction of sulfuric acid is 0.167-1.33%, react the above mixture at 40-60°C for 30-120min, pass TLC Observe the structural changes of products and impurities. The function of the concentrated sulfuric acid is as a catalyst in methyl esterification, and as H in the structural change of MELs + Provider, the amount of acid added will mainly affect the reaction time.

[0026] The rate of this reaction depends on the temperature and the amount of acid added. As shown in Table 1 below, the free fatty acid methyl esterification reaction is relatively fast, and the reaction can be completed within 10-30 minutes under the condition of concentrated sulfuric acid as a catalyst, and the conversion rate is close to 100%. However, it takes a long time to obtain hydrophilic MELs through this reaction. With the increase of the amount of acid added...

Embodiment 2

[0030] Take 2.5g of paste-like crude MELs product, dissolve it in 30ml of methanol, add 50μL (0.167%) concentrated sulfuric acid until the volume fraction of sulfuric acid is 0.167%, and react the above mixture at 50°C for 30min. Add 2 g of CaCO to methanol after the reaction 3 , adjust the pH to 6-7, and remove the solids by filtration. Add methanol to the obtained neutral solution, or concentrate by evaporation to adjust the concentration of MELs to 40-300g / L.

[0031] Divide the methanol solution of mannose erythritol lipid into three parts and add different proportions of n-hexane respectively. After the concentration adjustment, the volume ratio of MELs methanol solution to n-hexane is 1:1, 1:2, 1:3 respectively .

[0032] Thoroughly oscillate and mix on a spinner, then centrifuge at 12,000 rpm for 5 min, and discard the upper n-hexane phase. Then the above extraction process was repeated 3 times with n-hexane, the lower layer (methanol phase) was collected, and washed...

Embodiment 3

[0035] Take 2.5g of paste-like crude MELs product, dissolve it in 30ml of methanol, add 400μL of concentrated sulfuric acid until the volume fraction of sulfuric acid is 1.33%, and react the mixture at 50°C for 120min. After the reaction, three times the volume of pure water was added to the methanol phase, shaken evenly, and then centrifuged at 8000 rpm for 5 minutes to remove the upper liquid phase and collect the hydrophilic MELs neutral precipitate in the lower layer. In the method of the present invention, the pH adjustment method is to adjust the MELs solute, so that the solubility of MELs decreases and the H + Transfer to liquid and remove together.

[0036]Add methanol to the resulting precipitate and dilute to different concentrations (40-300g / L). Add n-hexane to the MELs methanol solution after concentration adjustment for extraction, the volume ratio of the methanol solution of the mannose erythritol lipid to n-hexane is 1:1-3, fully oscillating and mixing on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com