PET/ABS composite material and preparation method thereof, and refrigerator door hinge and production method thereof

A technology of composite materials and mixtures, applied in the field of PET/ABS composite materials and its preparation, refrigerator door hinges and its production, can solve the problems of short service life, poor aging resistance, etc., and achieve improved mechanical properties, smooth surface, excellent Effect of aging resistance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

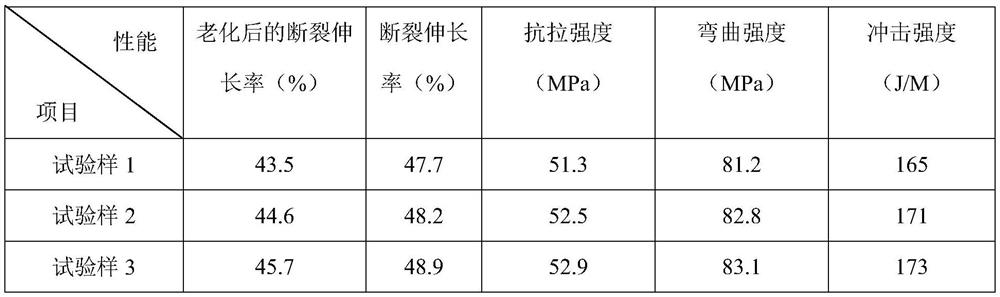

Examples

Embodiment 1-18

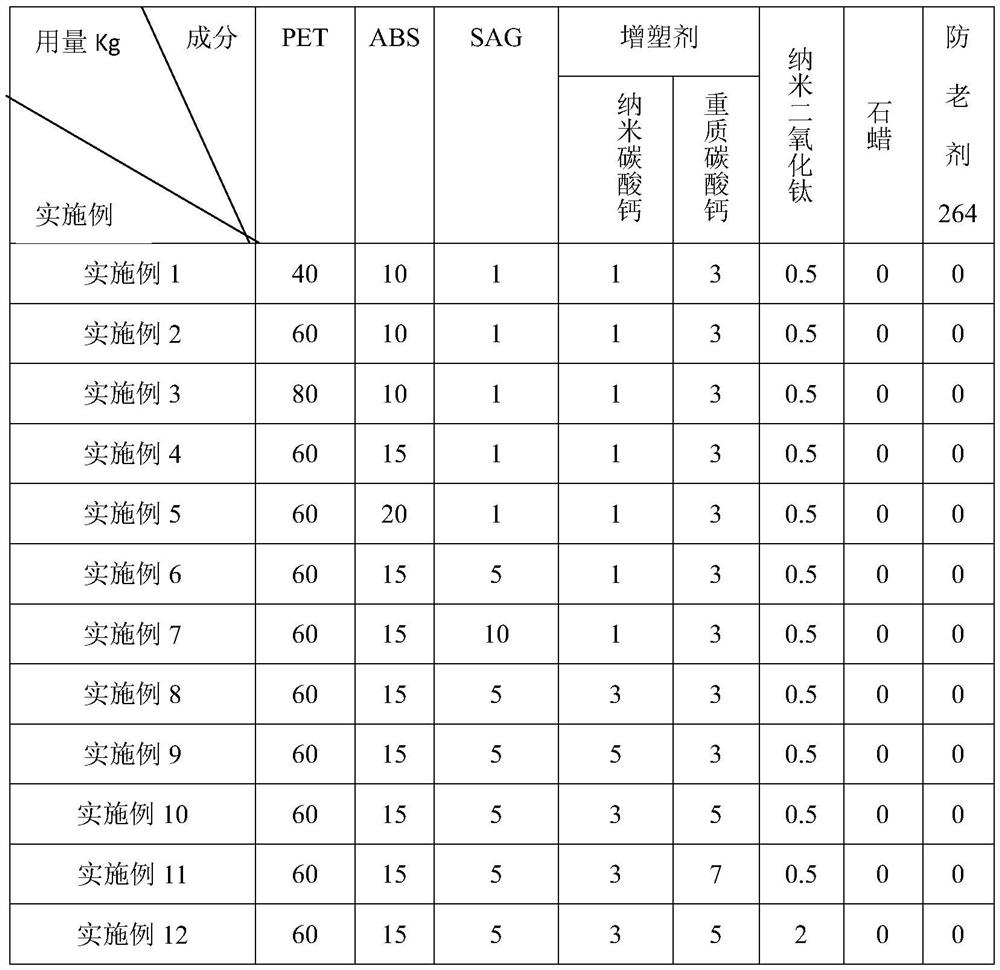

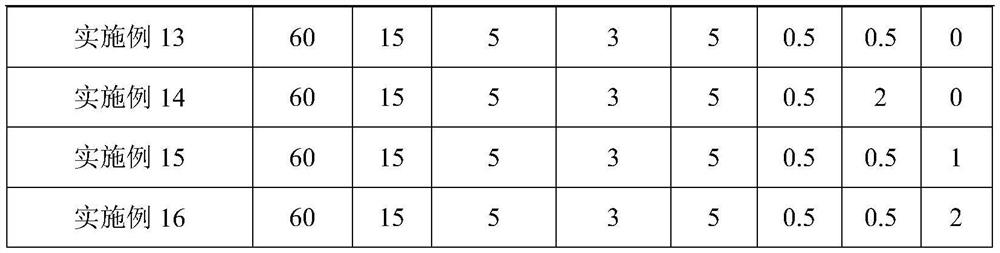

[0042] As described in Table 1, the main difference of Examples 1-18 is that the proportioning ratio of raw materials is different.

[0043] Below taking embodiment 1 as example to illustrate, the concrete prescription that the PET / ABS composite material that the application discloses implements is: PET40kg, ABS 10kg, styrene-acrylonitrile copolymer-glycidyl methacrylate terpolymer 1kg , Nano-calcium carbonate 1kg, heavy calcium carbonate 3kg, nano-titanium dioxide 0.5kg.

[0044] The embodiment of the present application also discloses a preparation method of a PET / ABS composite material, which specifically includes the following steps:

[0045] S1, weigh the raw materials according to the formula and mix them. Stir for 8 minutes under the conditions of heating temperature of 90°C and stirring speed of 300r / min, so that the raw materials are fully mixed to form a mixture;

[0046] S2, add the mixture to the twin-screw extruder for extrusion, cooling, and pelletizing to obtai...

Embodiment 17

[0052] The difference between this embodiment and embodiment 15 is that nano-titanium dioxide is replaced by nano-silver powder.

Embodiment 18

[0054] The difference between this example and Example 15 is that the nano-titanium dioxide is replaced by a quaternary ammonium salt compound.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com