Method for detecting concentration of polycrylamide

A polyacrylamide and detection method technology, which is applied to material inspection products, chemical analysis by titration, etc., can solve the problems of low detection range and resolution, poor accuracy, etc., and achieve fast application in mines, less detection time, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with embodiment the present invention will be further described:

[0015] One, the instrument that the present invention uses mainly contains: spectrophotometer, volumetric flask, pipette, purifier ball etc.

[0016] 2. The medicines used in this method mainly include: sodium acetate trihydrate, aluminum sulfate, NH 4 HF 2 , FeSO 4 , starch, CdI 2 Wait.

[0017] 3. Main reagents:

[0018] (1) Buffer solution: Weigh 25g of sodium acetate trihydrate and dissolve it in 800ml of deionized water, add 0.5g of aluminum sulfate, adjust the pH value to 4.0 with acetic acid, and then dilute to 1000ml for later use. Reducing agent: 4% NH 4 HF 2 -FeSO 4 solution. Starch-CdI 2 Reagent: weigh 11gCdI 2 Dissolve in 400ml of boiling water, add 2.5g of soluble starch, boil for 10 minutes, filter while hot, wash with water, and finally dilute to 1000ml for later use.

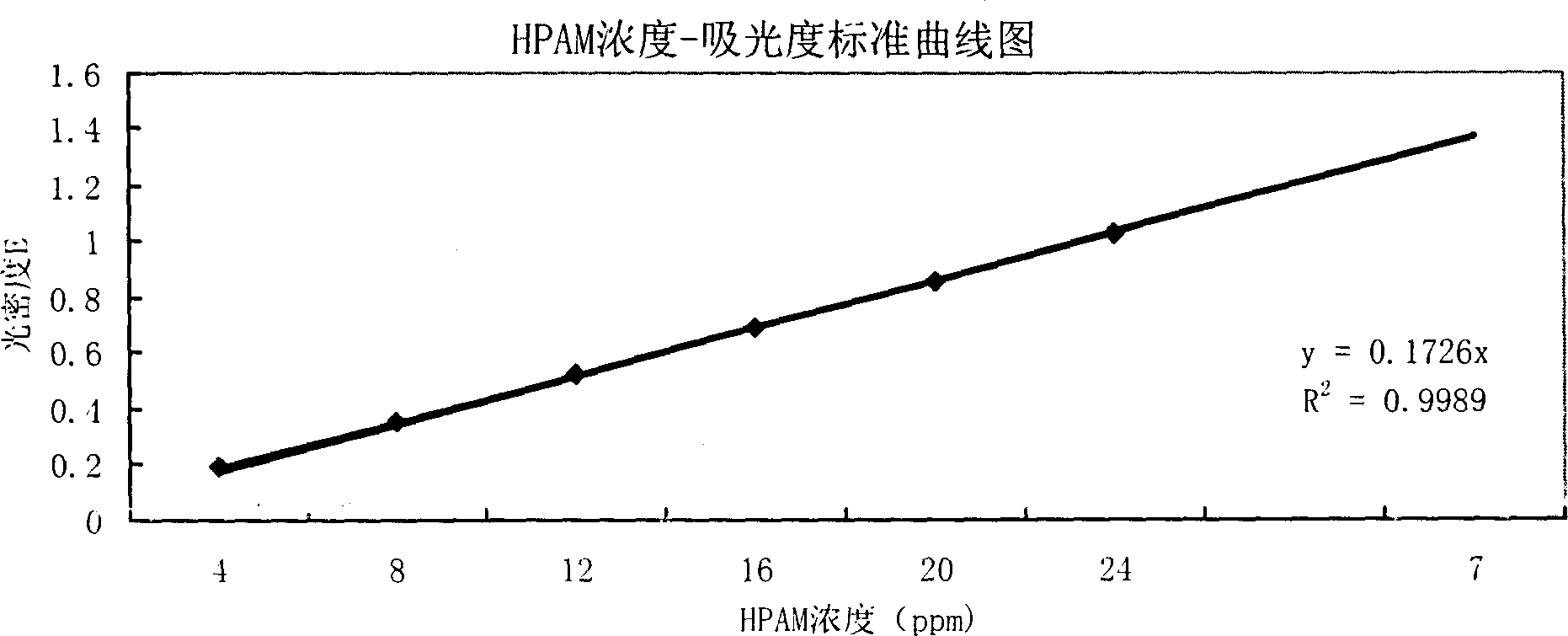

[0019] (2) Standard solution: Prepare polyacrylamide standard solutions with concentrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com