Composite activating agent for electroless nickel/immersion gold, preparation method of composite activating agent, and activating method

An electroless nickel-gold, composite technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problem of uneven distribution of palladium metal atoms, affecting the production quality of circuit boards, leakage plating and burrs, etc. , to achieve the effect of improving activation performance, reducing the width of infiltration plating, and reducing leakage plating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

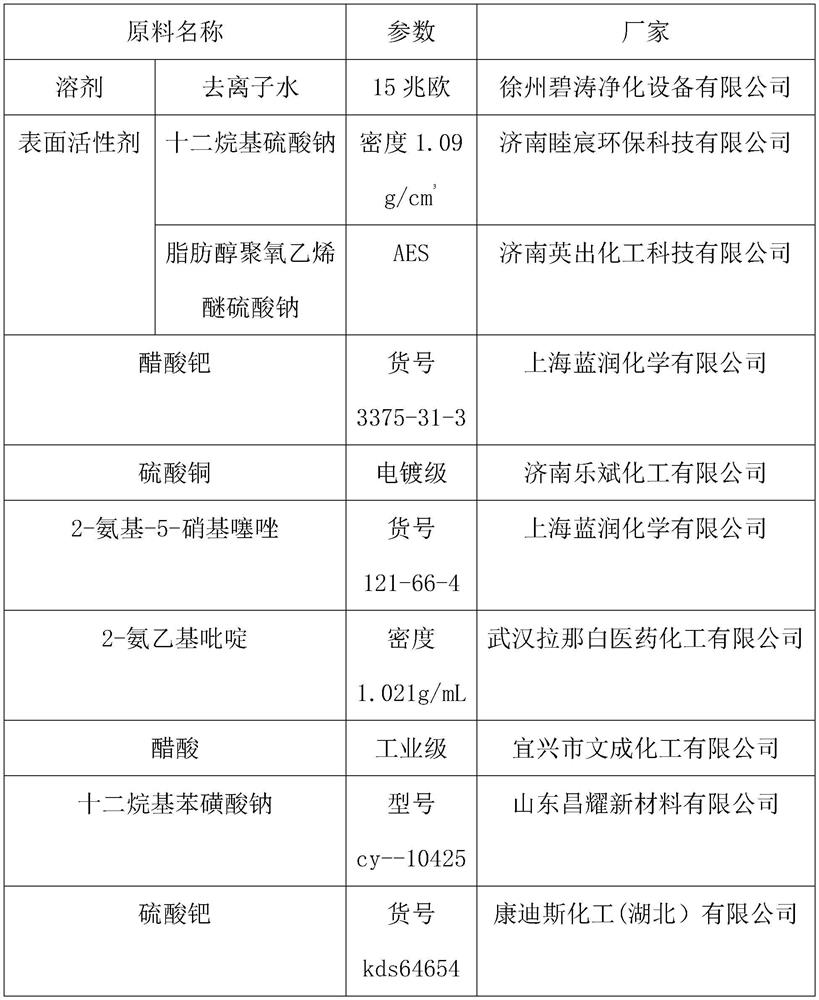

[0048] Embodiment 1-3 discloses a kind of composite activator, is made by including solvent, surfactant, palladium acetate, copper sulfate and synergist, and the weight of each raw material is shown in Table 2.

[0049] Table 2

[0050]

[0051] The preparation method of composite activator in embodiment 1-3 is as follows:

[0052] Weigh palladium acetate, 2-aminoethylpyridine and 2-amino-5-nitrothiazole respectively according to the weight in Table 2, mix the three, then heat to 35°C, and stir to obtain mixture A;

[0053] All the other raw materials are uniformly mixed with the mixture A according to the weight in Table 2 to obtain a composite activator.

Embodiment 4

[0055] The difference from Example 1 is that the synergist of Example 4 consists of 29 g of 2-aminoethylpyridine and 8 g of 2-amino-5-nitrothiazole.

Embodiment 5

[0057] The difference from Example 1 is that the raw material also includes 48g of acetic acid, and during preparation, acetic acid is added together with palladium acetate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com