Method for synthesizing high-crystallinity ZSM-35 molecular sieve without amine and ZSM-35 molecular sieve

A ZSM-35, high crystallinity technology, applied in molecular sieve catalysts, chemical instruments and methods, crystalline aluminosilicate zeolites, etc., can solve the problems of large ferrierite crystal grains, etc., and achieve environmental protection and molecular sieve production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0049] According to a preferred embodiment of the present invention, preferably H 2 O / SiO 2 25-28.

[0050] According to a preferred embodiment of the present invention, preferably SiO 2 / Al 2 o 3 15-300.

[0051] In the present invention, there is no special requirement on how to control the pH value of the mixture C, and common methods for adjusting the pH value can be used in the present invention, for example, an alkaline solution can be used to adjust the pH value of the mixture A and / or the mixture B above 9 To control the pH value of the mixture C above 9, according to a preferred embodiment of the present invention, it is preferred to use an alkaline solution to simultaneously adjust the pH values of the mixture A and the mixture B to be above 11 respectively to control the pH value of the mixture C above 11 , more preferably the pH of the mixture C is 11-13.5. Thus, the crystallinity of the molecular sieve synthesized by the present invention can be improved. ...

Embodiment 1

[0097] (1) Dissolve 1.233 g of sodium aluminate in 25 g of deionized water to obtain a clear solution, add 1.04 g of ZSM-35 molecular sieve seed crystals, and age at 60° C. for 4 hours to obtain mixture A;

[0098] (2) Add 13.9 g of silica sol to 5 g of deionized water under stirring, then add 4.23 g of sodium fluoride, and continue stirring for 1 hour to obtain mixture B;

[0099] (3) Dissolve 0.08 gram of sodium hydroxide and 0.8 gram of potassium hydroxide in 9 gram of deionized water, after obtaining the clear solution, divide it into two parts, add in the above-mentioned mixture A and mixture B respectively;

[0100] (4) Add mixture B to mixture A under stirring to obtain mixture C, and the pH value of mixture C is measured to be 12;

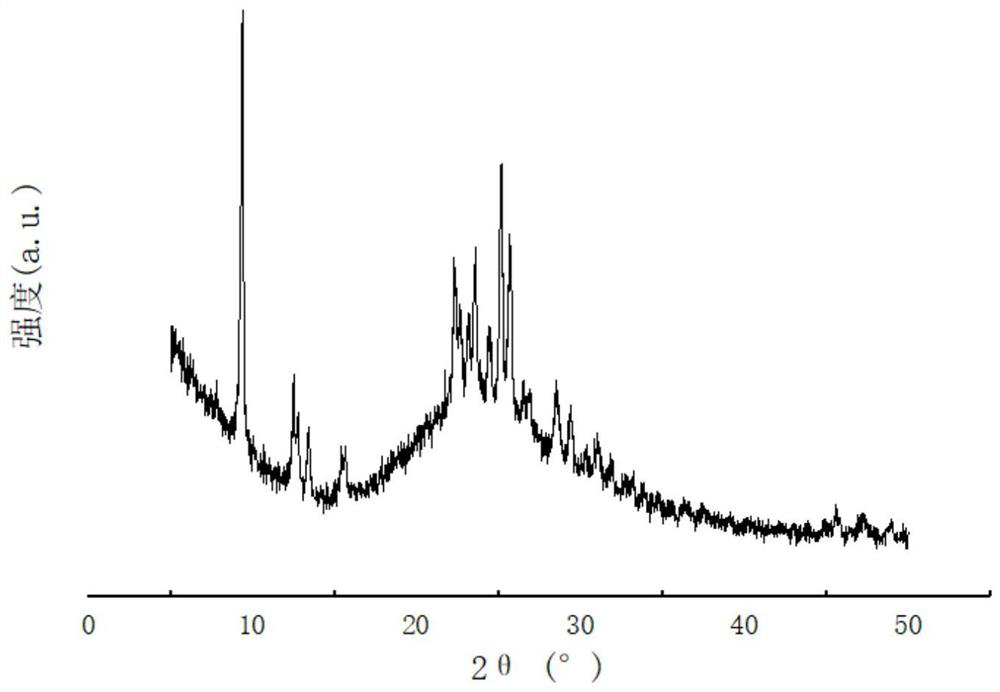

[0101] (5) The obtained mixture C was put into a stainless steel reaction kettle lined with polytetrafluoroethylene, and crystallized at 175° C. for 40 hours. Filter, wash, dry after crystallization is finished, obtain solid product 7.2 gr...

Embodiment 2

[0105] (1) Dissolve 0.12 g of sodium aluminate in 10 g of deionized water to obtain a clear solution, add 1.04 g of ZSM-35 molecular sieve seed crystals, and age at 60° C. for 4 hours to obtain mixture A;

[0106] (2) Add 0.4 g of sodium fluoride to 13.9 g of silica sol under stirring, and continue stirring for 1 hour to obtain mixture B;

[0107] (3) 0.08 gram of sodium hydroxide and 0.18 gram of potassium hydroxide were dissolved in 9 grams of deionized water, and after obtaining a clear solution, they were equally divided into two parts and added to the above-mentioned mixture A and mixture B respectively;

[0108] (4) Add mixture B to mixture A under stirring to obtain mixture C, and the pH value of mixture C is measured to be 11;

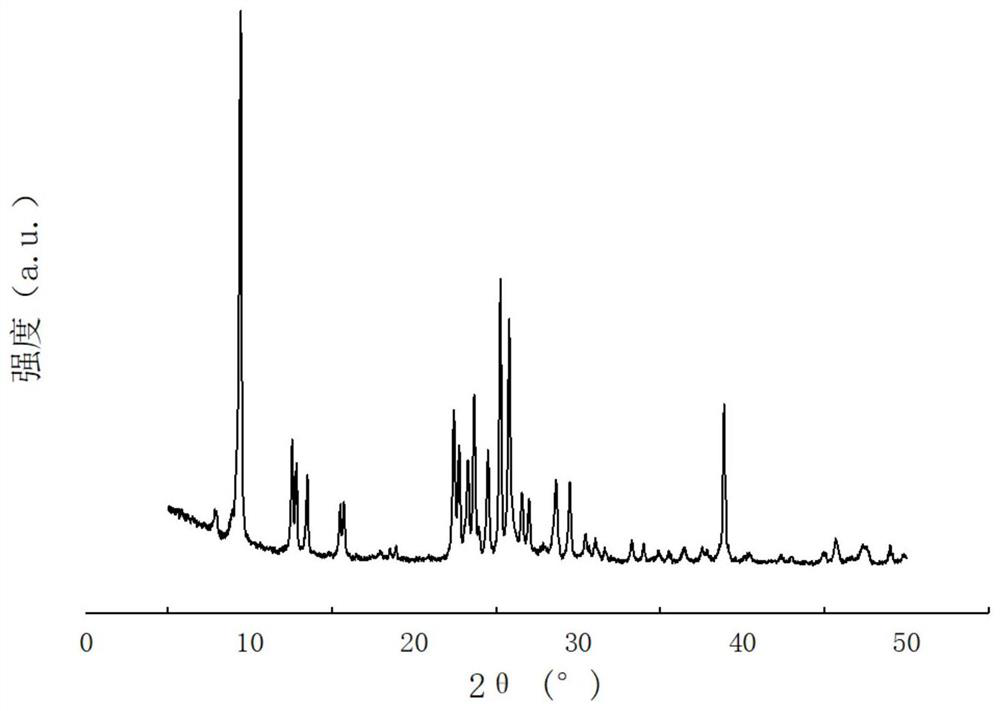

[0109] (5) The obtained mixture C was put into a stainless steel reaction kettle lined with polytetrafluoroethylene, and crystallized at 140° C. for 7 days. After the crystallization was completed, it was filtered, washed, and dried to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com