Amphiphilic block polymer nanoparticles with different morphologies and their preparation methods and applications

An amphiphilic block and nanoparticle technology, applied in the field of polymers, can solve problems such as complex processes, and achieve the effects of simple process, clear structure and shortened time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The invention provides a preparation method of amphiphilic block polymer nanoparticles with different morphologies, comprising the following steps:

[0037] The stabilizing segment monomer, the nucleating segment monomer, the Lewis acid, the Lewis base and the aromatic solvent are mixed, and the obtained mixed reaction solution is subjected to a polymerization reaction to obtain amphiphilic block polymer nanoparticles with different morphologies.

[0038] In the present invention, unless otherwise specified, all raw material components are commercially available commodities well known to those skilled in the art.

[0039] In the present invention, the stable segment monomer is an acrylate monomer, preferably including dimethylaminoethyl acrylate (DMAEA), diethylaminoethyl acrylate (DEAEA), methyl acrylate (MA) ethyl acrylate (EA), butyl acrylate (BA), 2-methoxyethyl acrylate (MEA) or 2-ethylhexyl acrylate (2-EHA). In the present invention, the nucleating segment monome...

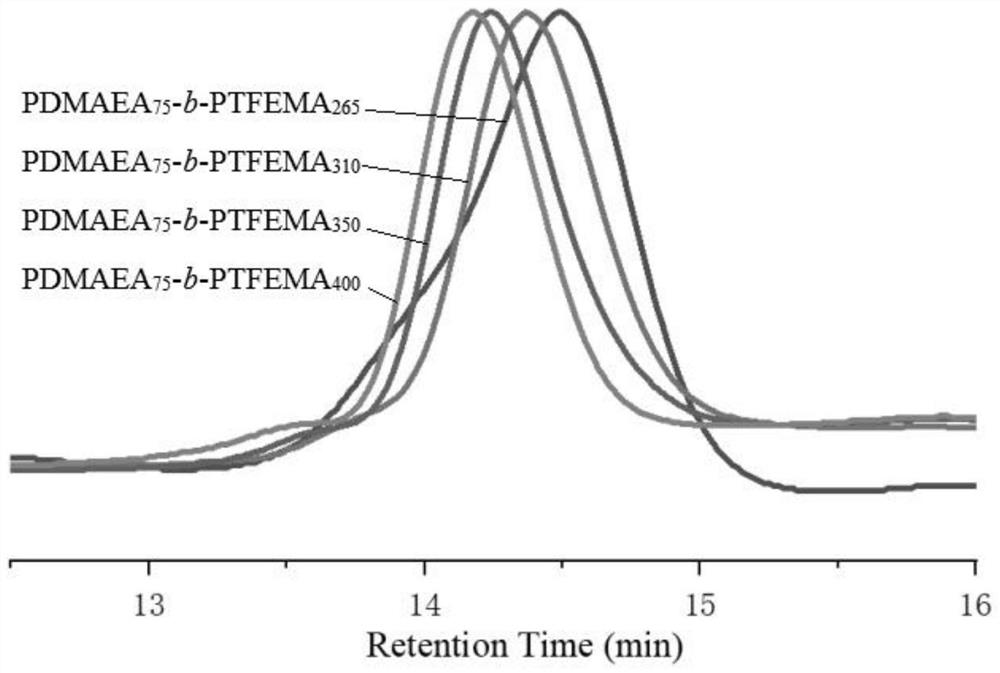

Embodiment 1

[0049] At room temperature, DMAEA and TFEMA were added to toluene at the same time, Lewis acid was added for premixing for 2 min, then Lewis base was added, and the obtained mixed reaction solution was subjected to polymerization reaction for 18 min to obtain an amphiphilic block polymer nanoparticle solution. After the morphology of the amphiphilic block polymer nanoparticles in the solution, n-hexane was added to the solution of the amphiphilic block polymer nanoparticles for quenching and then filtered. The obtained solid product was washed 3 times with n-hexane and then drained. , to obtain amphiphilic block polymer nanoparticles (denoted as PDMAEA 75 -b-PTFEMA 265 , where 75 and 265 represent the degree of polymerization), followed by subsequent characterization and testing.

[0050] Among them, Lewis base is Lewis acid as BHTAl i Bu 2 ; The solid content of the mixed reaction solution is 15%; the molar ratio of Lewis base: Lewis acid: DMAEA: TFEMA=1:2:75:265.

Embodiment 2~7

[0052] The amphiphilic block polymer nanoparticles were prepared according to the method of Example 1, and the preparation conditions were shown in Table 1:

[0053] Table 1 Preparation conditions of Examples 1 to 7

[0054]

[0055]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com