Process method for producing high-grade nickel matte from ferronickel blocks

A process method and high-nickel matte technology, applied in the production field of high-nickel matte, can solve the problems of complex process, limited resources and the like, and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

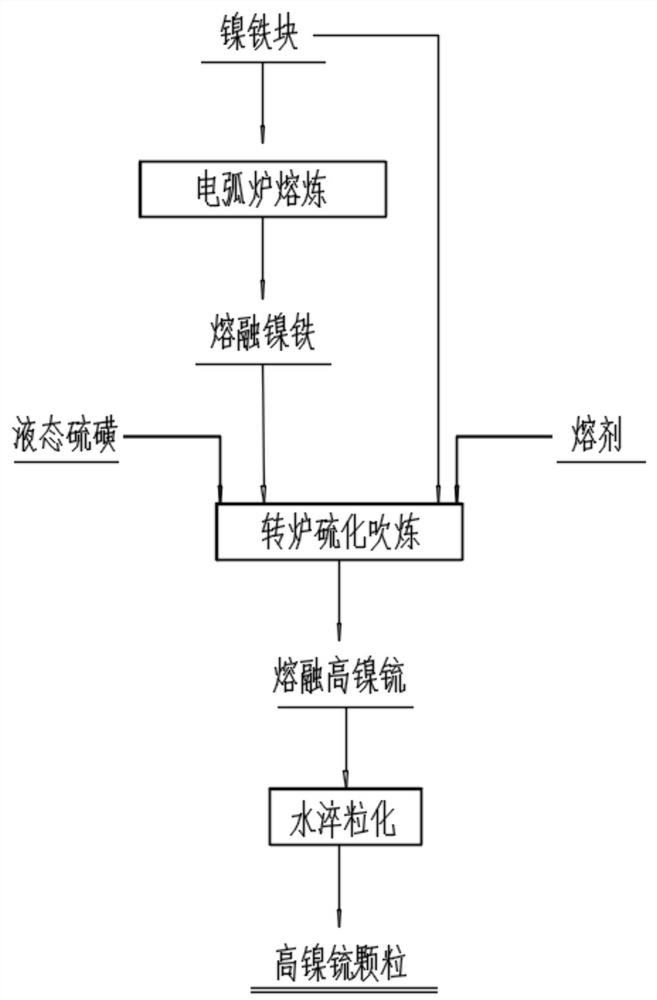

[0022] A process for producing high-nickel matte from ferronickel blocks, comprising the following steps: feeding ferronickel blocks into an electric arc furnace for smelting, sending molten ferronickel into a converter for vulcanization and blowing, and during the vulcanization and blowing processes Add liquid sulfur and quartz stone flux into the converter, vulcanize ferronickel to form nickel sulfide and ferrous sulfide, blow in air, first oxidize iron element and combine with quartz stone to form fayalite, remove iron and make slag, and finally The molten high-nickel matte melt remains, and the high-nickel matte melt is granulated by water quenching to form high-nickel matte particles.

[0023] The ferronickel block mainly for the stainless steel market is melted by an electric arc furnace; according to the difference in the grade of ferronickel, the operating temperature range of the electric arc furnace is 1450°C, and the molten nickel iron produced by the electric arc fu...

Embodiment 2

[0026] Such as figure 1 As shown, the present embodiment provides a process for producing high-nickel matte from ferronickel blocks, comprising the following steps: sending ferronickel blocks into an electric arc furnace for smelting, sending molten ferronickel into a converter for vulcanization and blowing, In the process of vulcanization and blowing, liquid sulfur and quartz stone flux are added to the converter. After ferronickel is vulcanized to form nickel sulfide and ferrous sulfide, air is blown in to oxidize the iron element first and combine with quartz stone to form fayalite. Iron slagging, the final molten high-nickel matte melt remains in the furnace, and the high-nickel matte melt is granulated by water quenching to form high-nickel matte particles.

[0027] The ferronickel block mainly for the stainless steel market will be melted in an electric arc furnace; according to the difference in the grade of ferronickel, the operating temperature range of the electric a...

Embodiment 3

[0030] Such as figure 1 As shown, the present embodiment provides a process for producing high-nickel matte from ferronickel blocks, comprising the following steps: sending ferronickel blocks into an electric arc furnace for smelting, sending molten ferronickel into a converter for vulcanization and blowing, In the process of vulcanization and blowing, liquid sulfur and quartz stone flux are added to the converter. After ferronickel vulcanizes to form nickel sulfide and ferrous sulfide, air is blown in to oxidize iron and combine with quartz stone to form fayalite, and remove iron. Slagging, and finally the molten high-nickel matte melt remains in the furnace, and the high-nickel matte melt is granulated by water quenching to form high-nickel matte particles.

[0031] The ferronickel block mainly for the stainless steel market will be melted in an electric arc furnace; according to the difference in the grade of ferronickel, the operating temperature range of the electric arc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com