Antibacterial flame-retardant chopped polypropylene fiber composite material and preparation method thereof

A polypropylene fiber and composite material technology, applied in the field of polypropylene fiber, can solve problems such as difficult to achieve mutual reinforcement mechanical properties, difficult to control matrix crystallization, weak fiber binding force, etc., achieve good long-term antibacterial effect, reduce agglomeration, and resist Good bending performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1 Preparation of Modified Carbon Nanotubes-SiO 2

[0039] Carbon nanotubes, SiO 2 , guar gum, and isopropanol were sequentially added in a mass ratio of 1:1:4.5:2.8, stirred and mixed evenly, and dried at 180°C for 7 hours to obtain; the modified carbon nanotube-SiO 2 Both adopt the modified carbon nanotube-SiO prepared in this example 2 .

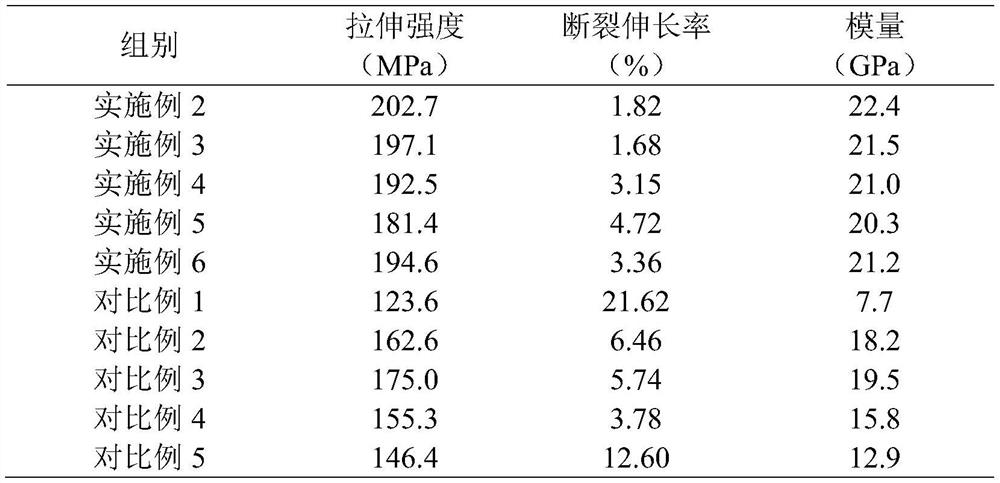

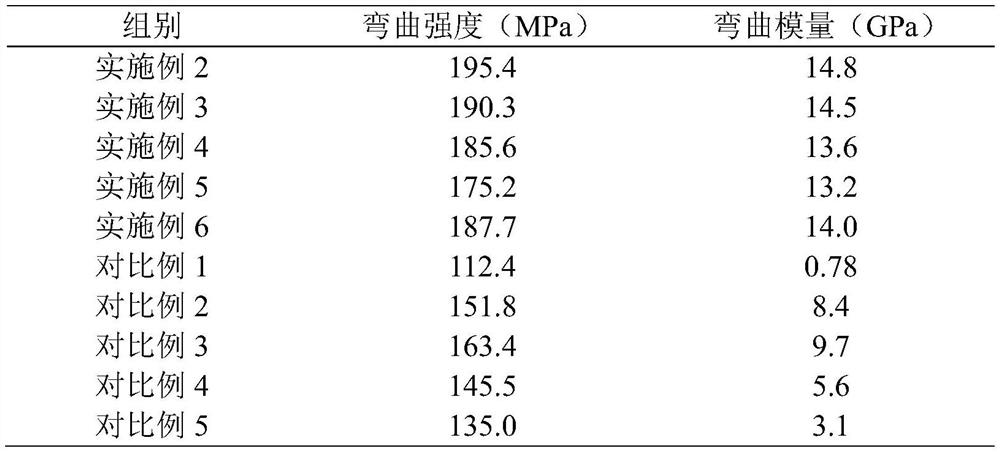

Embodiment 2

[0041] The composition of the mixed material of the antibacterial flame retardant chopped carbon fiber composite material is as follows:

[0042] The composite material consists of 5% bleached kraft softwood pulp, 25% chopped carbon fiber, 55% chopped polypropylene fiber, modified carbon nanotube-SiO 2 5%, silver oxide 5%, propylene oxide-lignin 5% composition;

[0043] The total amount of composite material feeding is 260kg;

[0044] The length of chopped carbon fiber is 6mm;

[0045] The length of the chopped polypropylene fiber is 5mm;

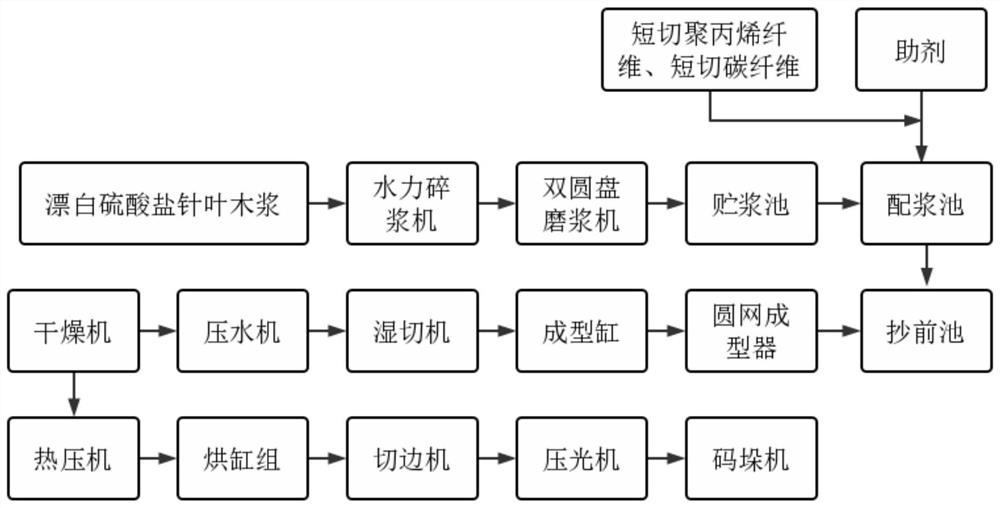

[0046] The specific preparation steps of antibacterial chopped carbon fiber composite materials are as follows:

[0047] S1. Pulp preparation: disintegrate the bleached kraft softwood pulp, then grind the pulp to 45 ° SR and store it in the pulp storage tank;

[0048] S2, slurry mixing: the stored bleached kraft softwood pulp, chopped carbon fiber, chopped polypropylene fiber, antibacterial agent, modified carbon nanotube-SiO 2 1. Pro...

Embodiment 3

[0054] The composition of the mixed material of the antibacterial chopped carbon fiber composite material is as follows:

[0055] The composite material consists of 8% bleached kraft softwood pulp, 28% chopped carbon fiber, 50% chopped polypropylene fiber, carbon nanotube-SiO 2 6%, silver oxide 4%, propylene oxide-lignin 4%;

[0056] The total amount of composite material feeding is 260kg;

[0057] The length of the chopped carbon fiber is 6mm;

[0058] The length of the chopped polypropylene fiber is 5mm;

[0059] The specific preparation steps of the antibacterial chopped carbon fiber composite material are consistent with those in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com