Biological material sterilization method and application thereof

A technology of biomaterials and beverages, which is applied in applications, preservation of food ingredients as antimicrobials, and preparation of alcoholic beverages. It can solve problems such as complex equipment and auxiliary equipment, questionable operational safety, and poor operating conditions. The effects of little impact on sensory and flavor, high safety and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A sterilizing method for fresh milk, said sterilizing method comprising the steps of:

[0059] (1) Put the fresh milk in a shaker at 20° C. with a rotation speed of 120 rpm for 12 hours, and carry out enrichment culture until the total number of colonies is 7.5 log to obtain pretreated fresh milk;

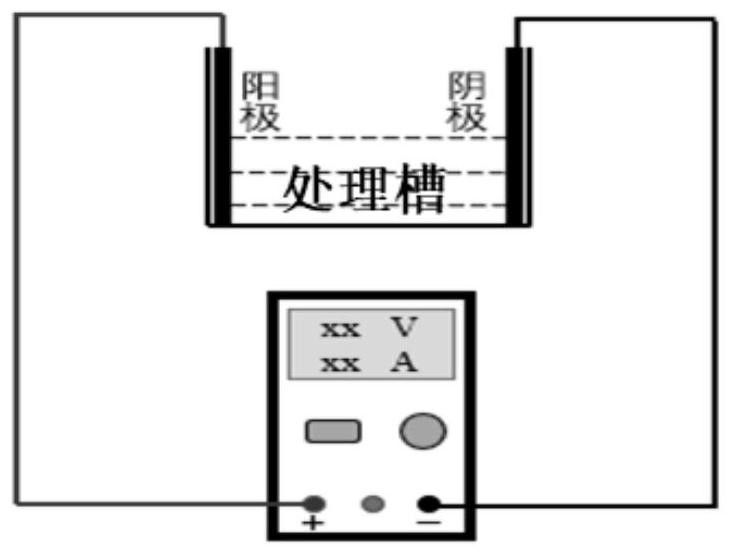

[0060] (2) Take 200mL of fresh milk pretreated in step (1) and place it in figure 1 In the treatment tank with cathode plate and anode plate installed as shown, the outside of the treatment tank is controlled by a 20°C low-temperature thermostat, so that the maximum temperature in the treatment tank is controlled at 55°C. Under the combined mode of constant pressure and constant current, The electric field strength is 9V / cm, the upper limit of the current is set to 0.6A (that is, when the system current increases to 0.6A, it will automatically switch to the constant current mode), and a low-voltage direct current electric field is applied to the treatment tank for 120min to ...

Embodiment 2

[0062] A sterilizing method for fresh milk, said sterilizing method comprising the steps of:

[0063] (1) Put the fresh milk in a shaker at 20° C. with a rotation speed of 120 rpm for 12 hours, and carry out enrichment culture until the total number of colonies is 7.5 log to obtain pretreated fresh milk;

[0064] (2) Put 200mL of fresh milk pretreated in step (1) into figure 1 In the treatment tank with the cathode plate and the anode plate installed as shown, the outside of the treatment tank is controlled by a 18°C low-temperature thermostat, so that the maximum temperature in the treatment tank is controlled at 55°C. Under the condition of a constant current of 0.6A, A low-voltage direct current electric field with a strength of 0.01-100 V / cm is applied to the treatment tank for 150 minutes to complete the sterilization treatment of the fresh milk.

Embodiment 3

[0066] A kind of sterilizing method of fresh milk, described sterilizing method comprises: 200mL fresh milk (total number of colonies is 4.8log) is placed in such as figure 1 In the treatment tank with the cathode plate and the anode plate installed as shown, the outside of the treatment tank is controlled by a 23°C low-temperature thermostat, so that the maximum temperature in the treatment tank is controlled at 55°C. Under the condition of a constant current of 0.6A, A low-voltage direct current electric field with a strength of 0.01-100 V / cm is applied to the treatment tank for 90 minutes to complete the sterilization treatment of the fresh milk.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com