Nano water-repellent antifouling down working clothes

A technology for work clothes and down, which is applied in the field of down jackets. It can solve the problems of inability to improve the microscopic roughness of the fabric surface, difficulty in achieving long-term water repellency, harm to the body and the environment, and achieve good flame-retardant effects, reduce static electricity, and low smoke generation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

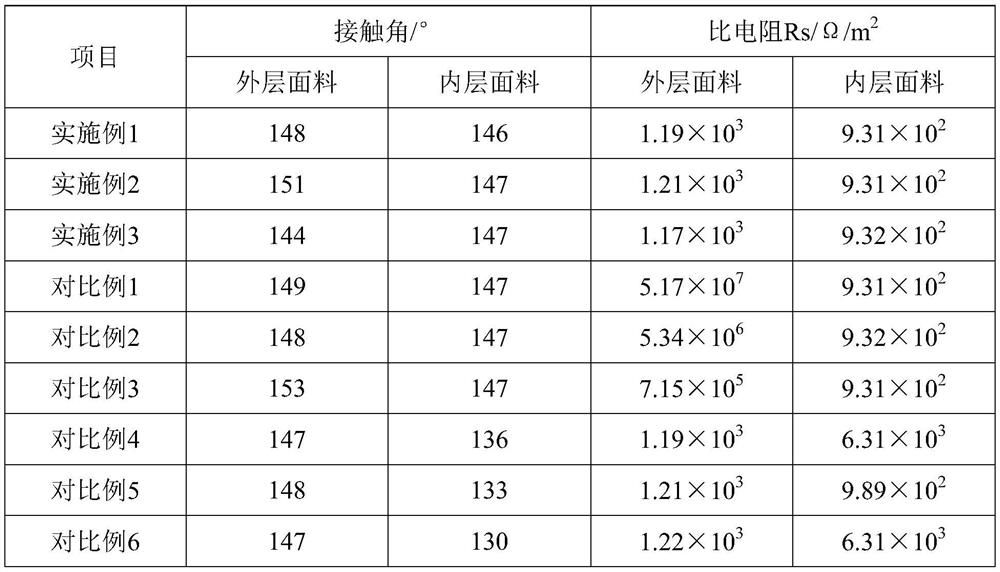

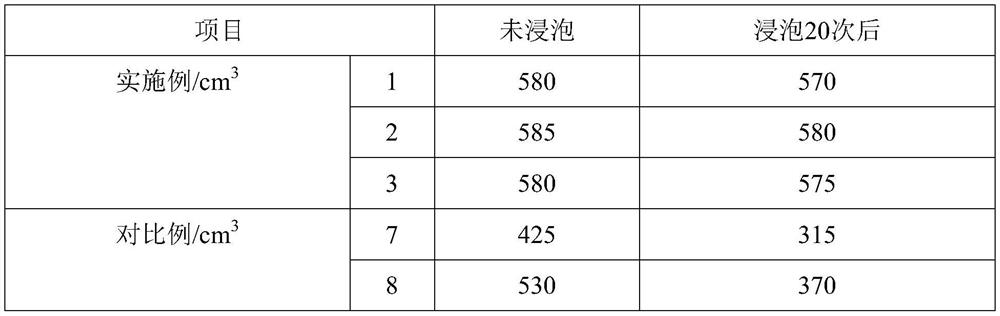

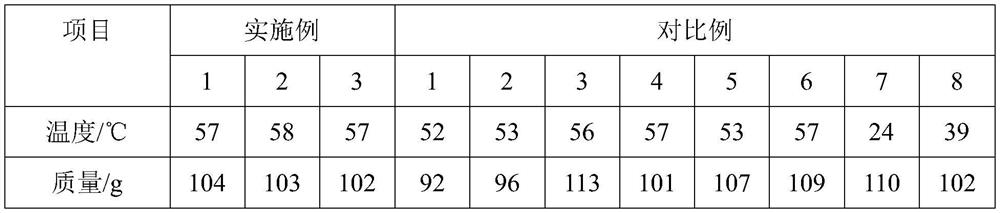

Examples

Embodiment 1

[0025] The nano water-repellent and antifouling down work clothes in the present embodiment comprise an outer fabric, an inner fabric, and a down filling layer arranged between the outer fabric and the inner fabric; the preparation method of the down work clothes comprises the following steps:

[0026] (1) The ordinary polyimide fiber is pickled with salicylic acid for 30 minutes, then taken out and drained, impregnated with ammonium chloride for 20 minutes, and then put into a continuous carbonization furnace with a temperature of 800 ° C and nitrogen atmosphere for 40 minutes. Finally, put it into a 400°C steam activation furnace for heating treatment for 30 minutes to obtain modified polyimide fibers, then compound the modified polyimide fibers and cotton fibers to obtain a built-in layer, and then coat the high-density spun and built-in layers After the cloth is glued and hot-bonded and pressed, put it on the reel in the vacuum chamber of the coating equipment, close the ch...

Embodiment 2

[0031] The nano water-repellent and antifouling down work clothes in this embodiment comprise an outer fabric, an inner fabric, and a down filling layer arranged between the outer fabric and the inner fabric; the preparation method of the down work clothes comprises the following steps:

[0032] (1) The common polyimide fiber was acid-washed with salicylic acid for 20 minutes, then drained and impregnated with ammonium chloride for 30 minutes, and then put into a continuous carbonization furnace with a temperature of 600 ° C and a nitrogen atmosphere for heat treatment for 60 minutes. Finally, put it into a 500°C steam activation furnace and heat it for 20 minutes to obtain modified polyimide fibers, then compound the modified polyimide fibers and cotton fibers to obtain a built-in layer, and then coat the high-density pongee and built-in layers After the cloth is glued and hot-bonded and pressed, put it on the reel in the vacuum chamber of the coating equipment, close the cham...

Embodiment 3

[0037] The nano water-repellent and antifouling down work clothes in the present embodiment comprise an outer fabric, an inner fabric, and a down filling layer arranged between the outer fabric and the inner fabric; the preparation method of the down work clothes comprises the following steps:

[0038] (1) The ordinary polyimide fiber was pickled with salicylic acid for 20 minutes, then drained and impregnated with ammonium chloride for 30 minutes, and then put into a continuous carbonization furnace with a temperature of 600 ° C and nitrogen atmosphere for 60 minutes. Finally, put it into a 400°C steam activation furnace and heat it for 30 minutes to obtain a modified polyimide fiber, then compound the modified polyimide fiber and cotton fiber to obtain a built-in layer, and then coat the high-density polyester tower spinning and built-in layer After the cloth is glued and hot-bonded and pressed, put it on the reel in the vacuum chamber of the coating equipment, close the cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com