L-ascorbyl palmitate modified small molecule peptide liposome as well as preparation and application thereof

A technology of ascorbyl palmitate and small molecular peptides, applied in the nano field, can solve the problems of poor absorption of small molecular peptides, and achieve the effects of good biocompatibility, simple preparation method and avoiding degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention provides a kind of preparation method of the above-mentioned L-ascorbyl palmitate modified small molecule peptide liposome, comprising the following steps:

[0038] (1) mix soybean lecithin and L-ascorbyl palmitate in absolute ethanol, get supernatant after centrifugation;

[0039] (2) The supernatant obtained in step (1) is rotary-evaporated under gradient decompression conditions to remove absolute ethanol to form a thin film;

[0040] (3) centrifuging after dissolving the small molecular peptide, taking the supernatant and hydrating the film obtained in step (2) to obtain a mixture;

[0041] (4) The mixture obtained in step (3) is broken and centrifuged, and the supernatant is retained; the precipitate is repeatedly broken and centrifuged to obtain a suspension of small molecule peptide liposomes modified with L-ascorbyl palmitate.

[0042] In one embodiment of the present invention, in step (2), the gradient decompression process is first to q...

Embodiment 1

[0050] This example provides a small molecule peptide liposome modified with L-ascorbyl palmitate.

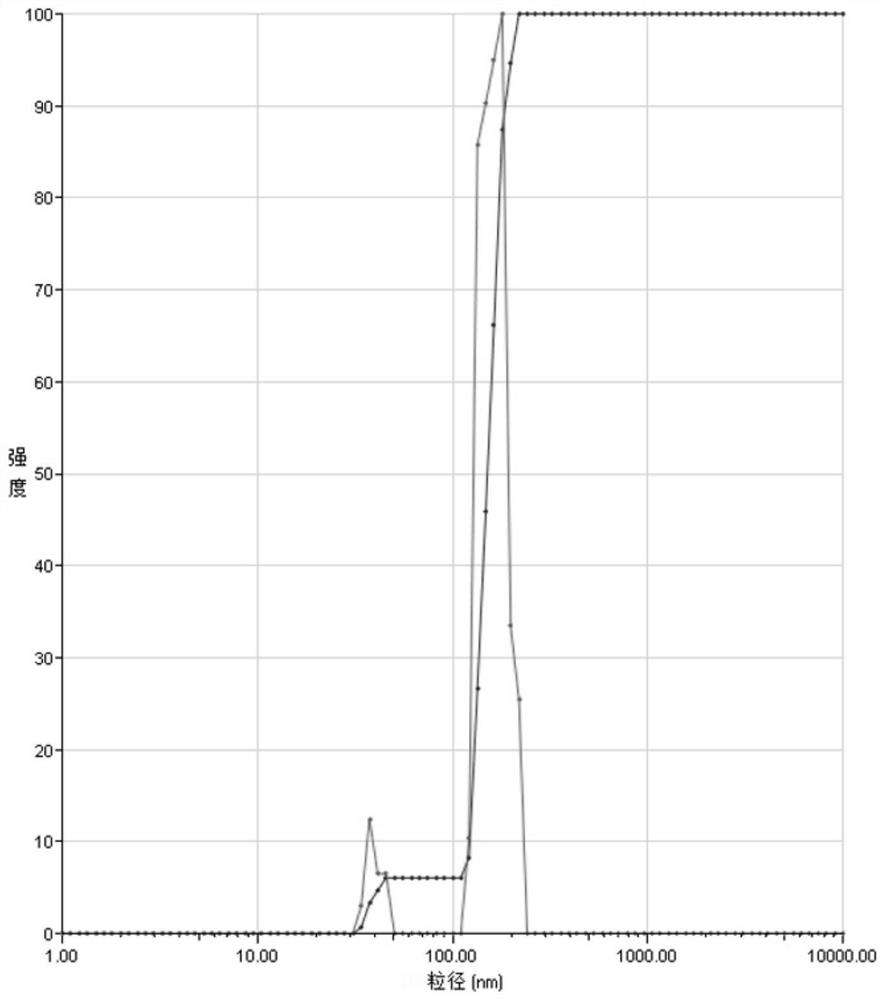

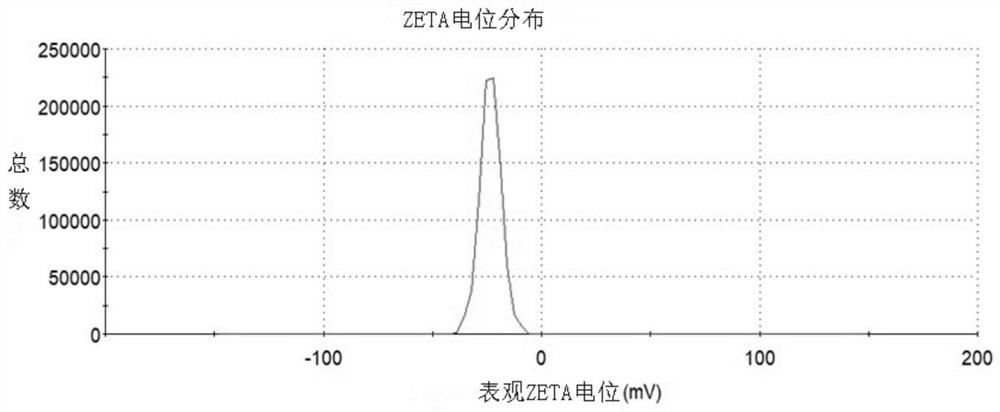

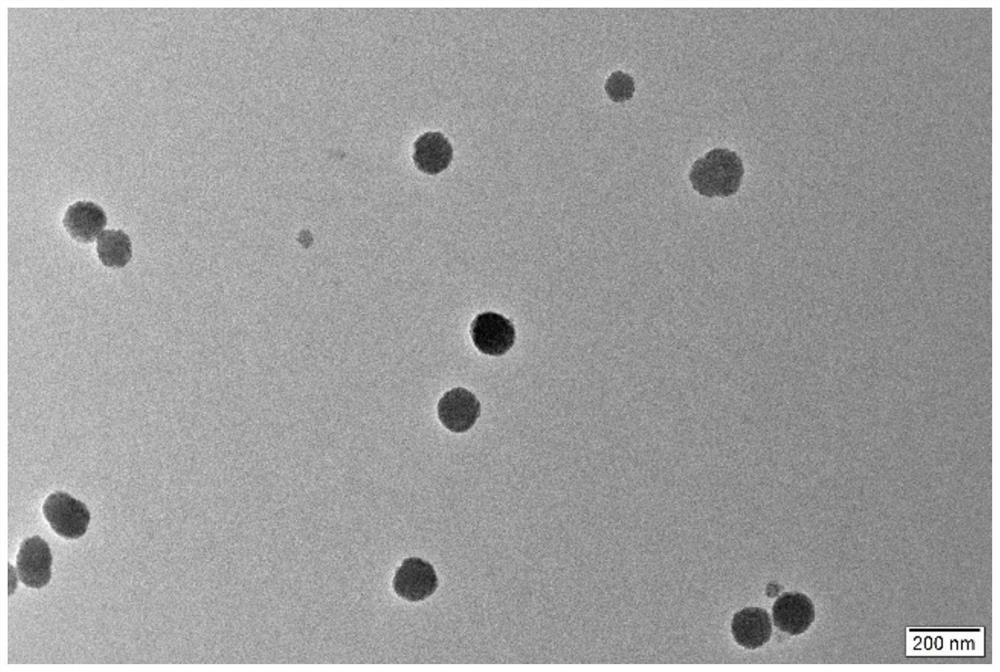

[0051] Dissolve 120 mg of soybean lecithin and 30 mg of L-ascorbyl palmitate in 40 mL of absolute ethanol, stir at room temperature for 1 hour, then centrifuge at 5000 g for 10 minutes, and take the supernatant. Transfer the supernatant into a rotary evaporating flask, first evaporate ethanol rapidly under the condition of a vacuum of 0.095MPa, then reduce the vacuum to 0.07MPa when the remaining solvent is about 10mL, and continue to slowly evaporate the remaining ethanol. The rotary evaporation temperature is At 41°C, the film was formed by rotary evaporation, and the solvent was removed. In addition, 10 mg of the small molecule peptide AFGIN was added to 15 mL of deionized water, and then the solution in which the small molecule peptide was dissolved was added to a rotary film-forming flask, and hydrated by rotating and shaking at 37°C for 1 hour at a frequency of 90 rpm. T...

Embodiment 2

[0053] This example provides a small molecule peptide liposome modified with L-ascorbyl palmitate.

[0054] Dissolve 100 mg of soybean lecithin and 20 mg of L-ascorbyl palmitate in 60 mL of absolute ethanol, stir at room temperature for 1 hour, then centrifuge at 5000 g for 10 minutes, and take the supernatant. Transfer the supernatant to a rotary evaporating flask, first evaporate ethanol rapidly under the condition of a vacuum of 0.09MPa, then reduce the vacuum to 0.06MPa when the remaining solvent is about 15mL, and continue to slowly evaporate the remaining ethanol. The rotary evaporation temperature is At 45°C, the film was formed by rotary evaporation, and the solvent was removed. In addition, 10 mg of the small molecular peptide QDGNPL was added to 10 mL of deionized water, and then the solution in which the small molecular peptide was dissolved was added to a rotating film-forming flask, and hydrated by rotating and shaking at 45°C for 1 hour at a frequency of 160 rpm....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| encapsulation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com