Liquid organic hydrogen storage device and method

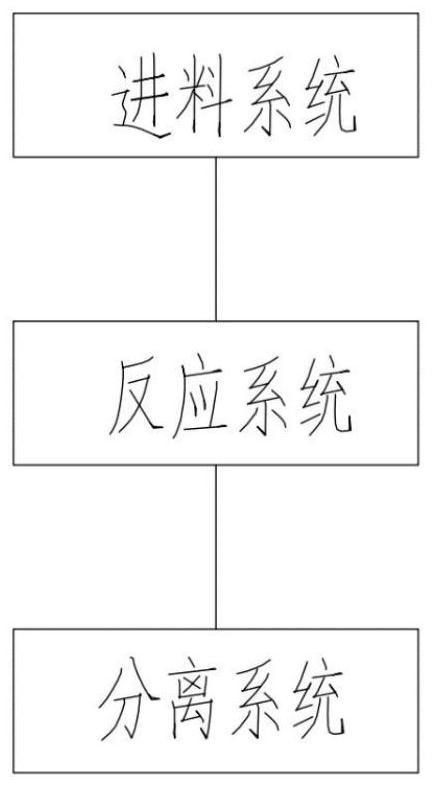

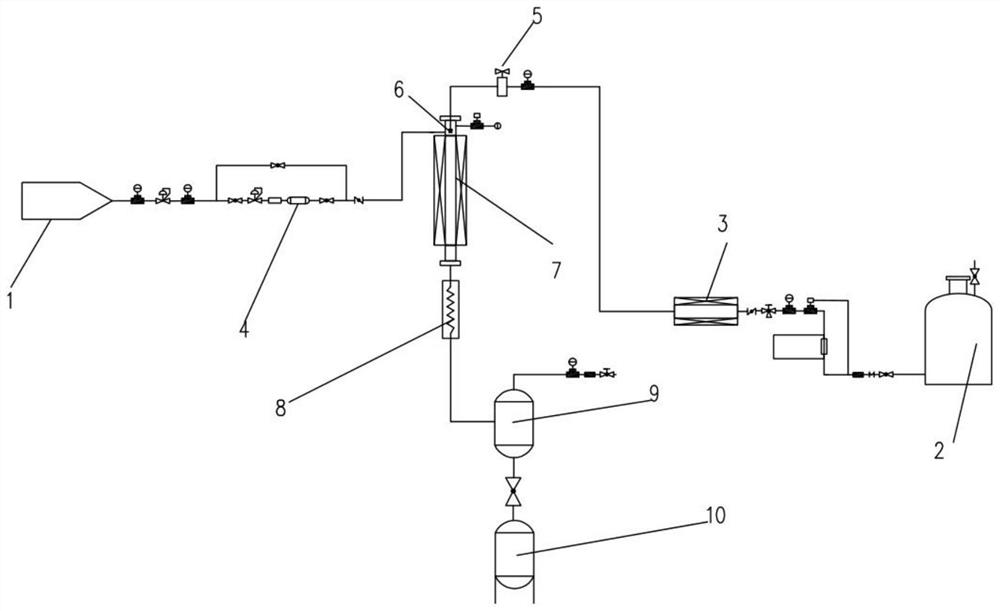

A hydrogen storage device and organic technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve the problems of affecting hydrogen storage efficiency, small contact area, high cost of use, etc., and achieve the effect of improving reaction efficiency and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

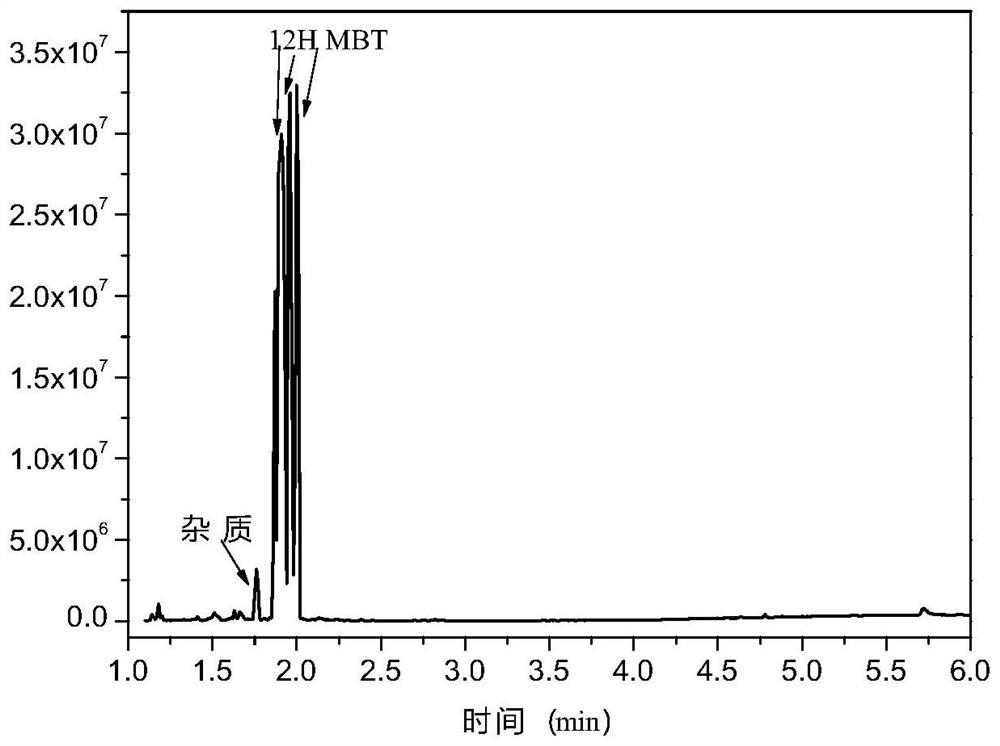

specific example 1

[0060] Using benzyltoluene as hydrogen storage raw material:

[0061] Step a: Before the reaction starts, use a helium leak detector to detect the pipeline, and to ensure that the pipeline is not leaking, use nitrogen to purge the entire pipeline so that there are no other impurity gases in the pipeline;

[0062] Step b: After the temperature is raised to 200°C, hydrogen gas is introduced. During the process of introducing hydrogen, the temperature will drop slightly. After the hydrogen pressure reaches 6MPa, keep it for a period of time to stabilize the temperature. At this time, the pressure range of the electromagnetic valve is set to 6.1-7.1 MPa, and the flow rate of benzyl toluene is set to 5 ml / min by the advection pump. When the temperature returns to the predetermined temperature, open the solenoid valve and the flow pump to feed;

[0063] Step c: After the solenoid valve receives the liquid pressure signal, it automatically opens the valve, and the liquid enters the...

specific example 2

[0066] Using dibenzyltoluene as hydrogen storage raw material:

[0067] Step a: Before the reaction starts, use a helium leak detector to detect the pipeline, and to ensure that the pipeline is not leaking, use nitrogen to purge the entire pipeline so that there are no other impurity gases in the pipeline;

[0068] Step b: After the temperature is raised to 200°C, hydrogen gas is introduced. During the process of introducing hydrogen, the temperature will drop slightly. After the hydrogen pressure reaches 7MPa, keep it for a period of time to stabilize the temperature. At this time, the pressure range of the electromagnetic valve is set to 7.1-8.1 MPa, and the flow rate of dibenzyltoluene is set to 2 ml / min by the advection pump. When the temperature returns to the predetermined temperature, open the solenoid valve and the flow pump to feed;

[0069] Step c: After the solenoid valve receives the liquid pressure signal, it automatically opens the valve, and the liquid enters ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap