Method for extracting titanium dioxide from titanium-containing blast furnace slag

A technology of titanium dioxide and blast furnace slag, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of resource waste, unstable titanium alloy composition, and substandard physical and mechanical properties, so as to improve product quality, yield, and treatment The process is simple and easy, and the effect of the titanium extraction process is optimized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

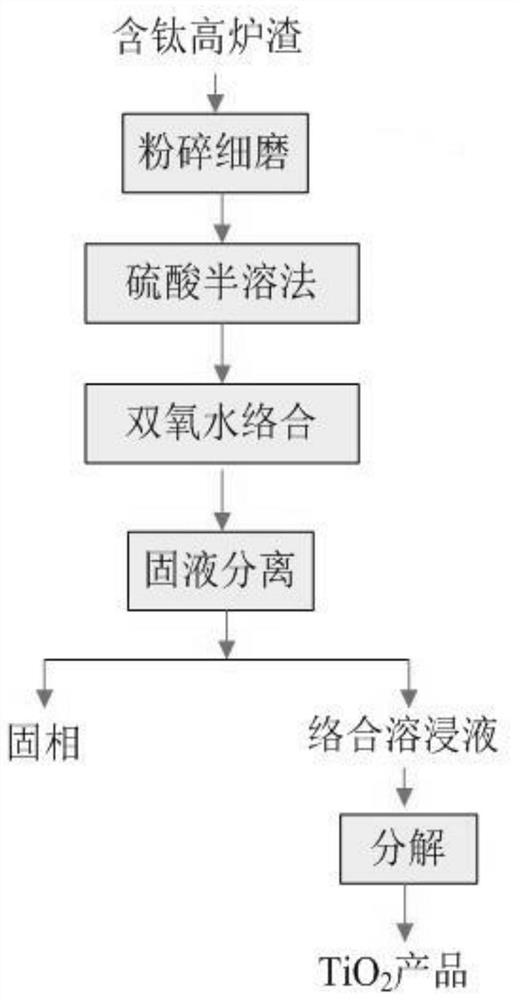

[0042] The steps of the method for extracting titanium dioxide from titanium-containing blast furnace slag are as follows:

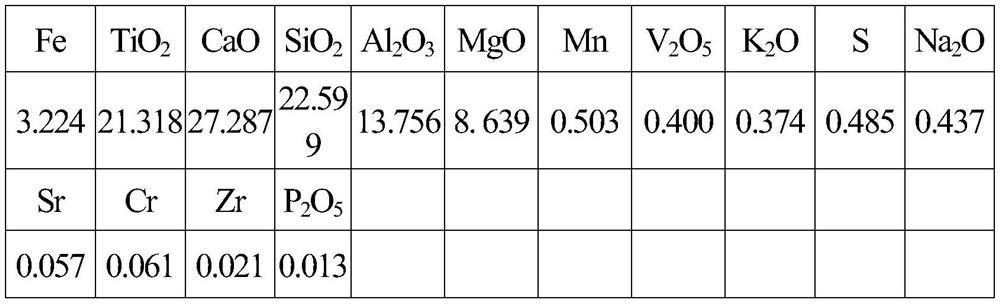

[0043]A. Dry the titanium-containing blast furnace slag and grind it into powder: Take 1000g of blast furnace slag and dry it at 100-110°C for 2-4 hours to constant weight, grind it to -200 mesh (2 The content is 21.318%;

[0044] Table 1 The main chemical composition of Leshan Desheng blast furnace slag (mass percentage%)

[0045]

[0046] B. First add quantitative sulfuric acid to the blast furnace slag powder and stir evenly, then add quantitative hydrogen peroxide and let it stand in the dark for 1 hour to obtain the soaked mixture; wherein, the mass ratio of blast furnace slag powder: sulfuric acid: hydrogen peroxide is 1:0.9 : 0.55, sulfuric acid concentration 98%, hydrogen peroxide concentration 30%;

[0047] C. Separating the soaked mixture from solid to liquid, and washing the filter cake with hydrogen peroxide to obtain a hydrogen peroxide ...

Embodiment 2

[0050] Same as Example 1, the only difference is that the concentration of hydrogen peroxide used is 35%; in step B, the mass ratio of blast furnace slag powder: sulfuric acid: hydrogen peroxide is 1: 0.9: 0.6; in step D, 162.05 g of titanium dioxide, TiO 2 The recovery rate was 76.01%.

Embodiment 3

[0052] Same as Example 1, the only difference is that the concentration of hydrogen peroxide used is 25%; in step B, the mass ratio of blast furnace slag powder: sulfuric acid: hydrogen peroxide is 1: 0.9: 0.5; in step D, 158.02 g of titanium dioxide, TiO 2 The recovery rate was 74.12%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com