Foamed ceramic and preparation method thereof

A technology of foam ceramics and silt, applied in the field of foam ceramics and its preparation, can solve the problems of mechanical strength and high porosity, and achieve a balance between flexural strength and porosity, high porosity, and strong gas sealing ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

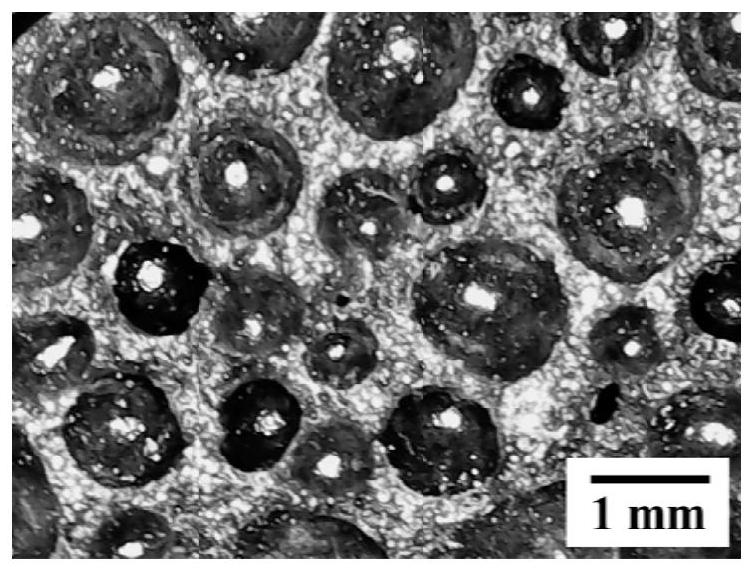

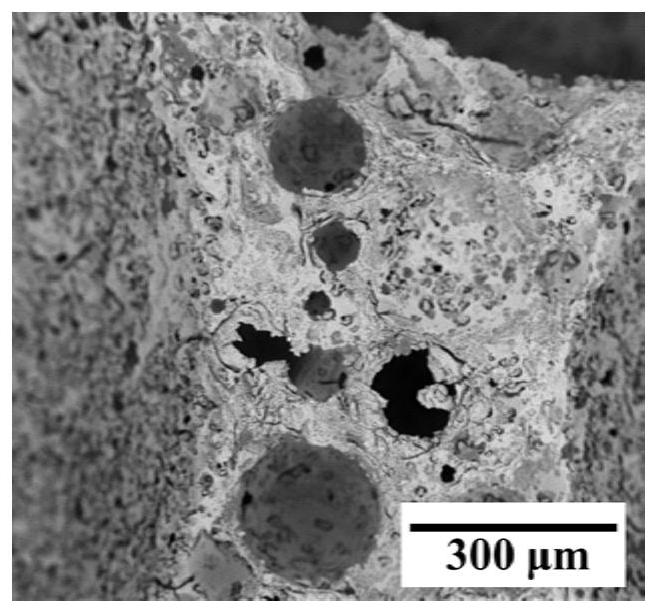

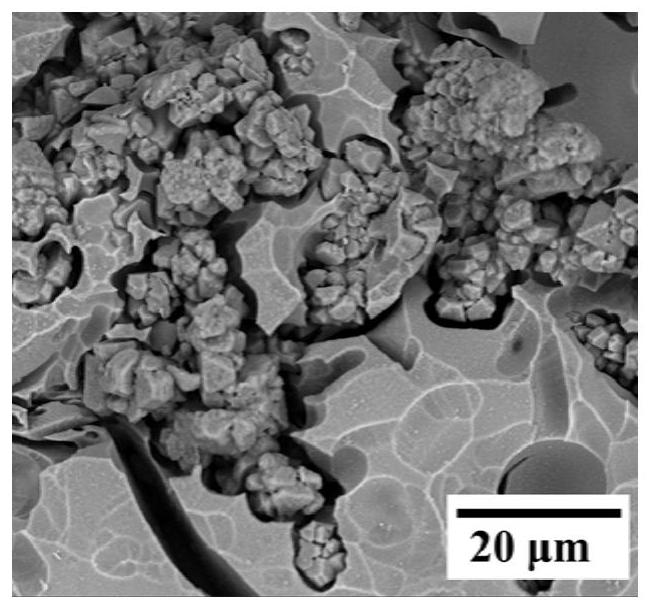

Image

Examples

Embodiment 1

[0032] This embodiment provides a kind of foamed ceramics, including the following raw materials: 75g of silty shale, 10g of fly ash, 15g of steel slag, 0.2g of silicon carbide; the particle size of the silty shale is 80 mesh, and the The particle size is 100 mesh, the particle size of steel slag is 100 mesh, and the particle size of silicon carbide is 700 mesh; in terms of mass percentage, the composition of the silty shale includes 67.79% SiO 2 , 8.52% CaO, 7.64% Al 2 o 3 , 3.28% Fe 2 o 3 , 1.66% MgO, 1.37% K 2O; In terms of mass percentage, the composition of fly ash includes 45.10% SiO 2 , 23.89%Al 2 o 3 , 12.86% Fe 2 o 3 , 3.33% CaO, 1.72% K 2 O, 1.60% Na 2 O, 1.29% MgO; in terms of mass percentage, the composition of steel slag includes 42.25% CaO, Fe 2 o 3 +FeO25.14%, 15.60%SiO 2 , 7.07% MgO, 1.80% Al 2 o 3 .

[0033] The preparation method of above-mentioned ceramic foam comprises the steps:

[0034] (1) Mix silty shale, fly ash, steel slag, and silico...

Embodiment 2

[0038] This embodiment provides a kind of foamed ceramics, including the following raw materials: 70g of silty shale, 17g of fly ash, 13g of steel slag, 0.2g of silicon carbide; the particle size of the silty shale is 150 mesh, and the The particle size is 150 mesh, the particle size of steel slag is 150 mesh, and the particle size of silicon carbide is 700 mesh; in terms of mass percentage, the composition of the silty shale includes 67.79% SiO 2 , 8.52% CaO, 7.64% Al 2 o 3 , 3.28% Fe 2 o 3 , 1.66% MgO, 1.37% K 2 O; In terms of mass percentage, the composition of fly ash includes 45.10% SiO 2 , 23.89%Al 2 o 3 , 12.86% Fe 2 o 3 , 3.33% CaO, 1.72% K 2 O, 1.60% Na 2 O, 1.29% MgO; in terms of mass percentage, the composition of steel slag includes 42.25% CaO, Fe 2 o 3 +FeO25.14%, 15.60%SiO 2 , 7.07% MgO, 1.80% Al 2 o 3 .

[0039] The preparation method of above-mentioned ceramic foam comprises the steps:

[0040] (1) Mix silty shale, fly ash, steel slag, and sili...

Embodiment 3

[0043] This embodiment provides a kind of foamed ceramics, including the following raw materials: 65g of silty shale, 18g of fly ash, 17g of steel slag, 0.3g of silicon carbide; the particle size of the silty shale is 100 mesh, and the The particle size is 100 mesh, the particle size of steel slag is 100 mesh, and the particle size of silicon carbide is 700 mesh; in terms of mass percentage, the composition of the silty shale includes 67.79% SiO 2 , 8.52% CaO, 7.64% Al 2 o 3 , 3.28% Fe 2 o 3 , 1.66% MgO, 1.37% K 2 O; In terms of mass percentage, the composition of fly ash includes 45.10% SiO 2 , 23.89%Al 2 o 3 , 12.86% Fe 2 o 3 , 3.33% CaO, 1.72% K 2 O, 1.60% Na 2 O, 1.29% MgO; in terms of mass percentage, the composition of steel slag includes 42.25% CaO, Fe 2 o 3 +FeO25.14%, 15.60%SiO 2 , 7.07% MgO, 1.80% Al 2 o 3 .

[0044] The preparation method of above-mentioned ceramic foam comprises the steps:

[0045] (1) Mix silty shale, fly ash, steel slag, and sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com