Special fertilizer for rice and preparation method and application thereof

A special fertilizer and rice technology, applied in the field of rice special fertilizer and its preparation, can solve the problems of poor health, weakened resistance to germs, easy to get sick, etc., and achieve the effects of improving quality, promoting rice growth, and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

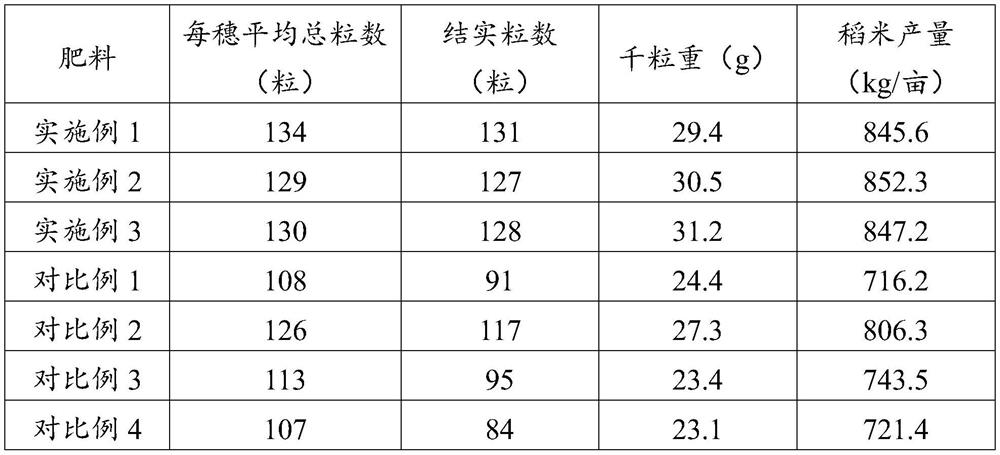

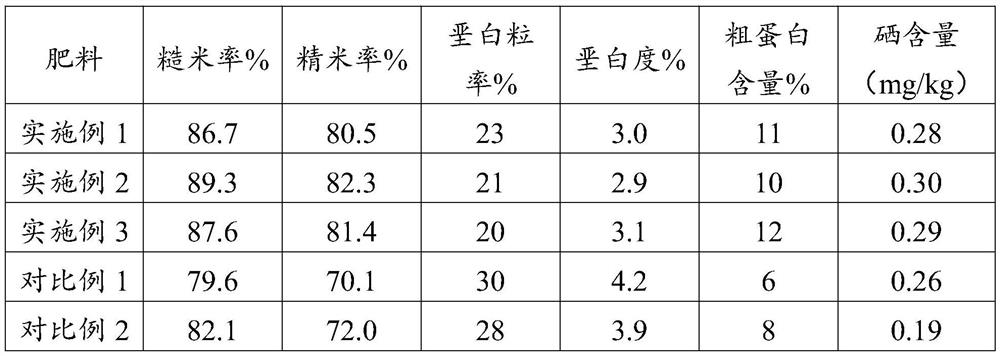

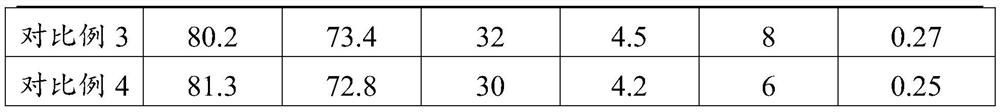

Examples

preparation example Construction

[0053] The present invention also provides the preparation method of described special fertilizer for rice, comprising the steps of:

[0054] (1) Mix feces, straw and microbial inoculum to obtain fermented material, and accumulate and ferment the fermented material for 26-30 days to obtain decomposed organic material;

[0055] (2) Mix the decomposed organic material with urea, dicalcium hydrogen phosphate, diammonium hydrogen phosphate, potassium chloride, potassium fulvic acid, glutamic acid, amino acid chelated zinc and amino acid chelated selenium, and granulate to obtain rice special Fat.

[0056] In the present invention, the accumulation fermentation time is preferably 27-29 days, more preferably 28 days; the water content of the fermentation material during the accumulation fermentation is 61-65%, preferably 62-64%, more preferably 63% ;

[0057] The central temperature of the fermentation heap during the stacking fermentation is 30-60°C, preferably 40-50°C, more pref...

Embodiment 1

[0080] Take 50 kg of cow dung, 30 kg of corn stalks, 30 kg of soybean stalks, 0.2 kg of Bacillus subtilis inoculum, and 1.2 kg of Trichoderma inoculum, and mix them evenly to obtain a fermentation material. Stack and ferment the fermented material at a water content of 61%, and keep the central temperature of the fermentation pile between 30 and 60°C. When the central temperature of the fermentation pile is greater than 60°C, turn the pile immediately. When the temperature is lower than 30°C, the film shall be kept warm. The fermented material was stacked and fermented for 26 days to obtain decomposed organic material.

[0081] Add 28kg urea, 8kg dicalcium hydrogen phosphate, 10kg diammonium hydrogen phosphate, 12kg potassium chloride, 3kg potassium fulvic acid, 2kg glutamic acid, 1.5kg amino acid chelated zinc, 6kg amino acid chelated selenium in the decomposed organic material, Mix evenly, add to a granulator, and granulate to obtain special fertilizer for rice.

[0082] 5...

Embodiment 2

[0086] Take 56kg of chicken manure, 58kg of soybean stalks, 0.25kg of Bacillus subtilis inoculum, and 1.75kg of Trichoderma inoculum, and mix them evenly to obtain the fermentation material. Stack and ferment the fermented material at a water content of 62%, and keep the center temperature of the fermentation pile between 30 and 60°C. When the center temperature of the fermentation pile is higher than 60°C, turn the pile immediately. When the temperature is lower than 30°C, the film shall be kept warm. The fermented material was stacked and fermented for 30 days to obtain decomposed organic material.

[0087] Add 30kg urea, 10kg dicalcium hydrogen phosphate, 9kg diammonium hydrogen phosphate, 10kg potassium chloride, 6kg potassium fulvic acid, 1kg glutamic acid, 2kg amino acid chelated zinc, 5kg amino acid chelated selenium to the decomposed organic material, mix Evenly, add to the granulator and granulate to obtain special fertilizer for rice.

[0088] 6 days before rice tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com