Emulsion type acrylate pressure-sensitive adhesive capable of being repeatedly uncovered and pasted

A pressure-sensitive adhesive and acrylate technology, which is applied in the field of pressure-sensitive adhesives, can solve the problems of large sizing thickness, easy coating stickiness, easy occurrence of adhesion, etc. Smooth and safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

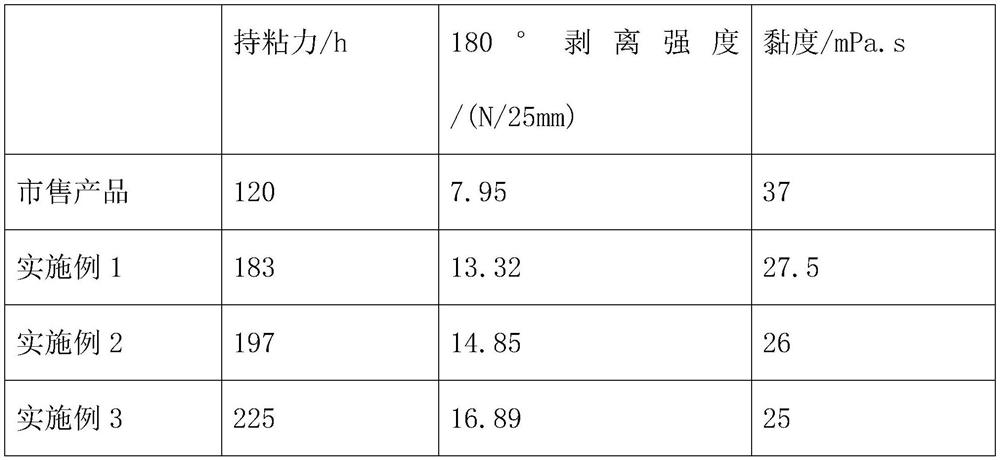

Embodiment 1

[0026] The invention provides a reusable emulsion-type acrylate pressure-sensitive adhesive for peeling and sticking. The raw materials used (by weight) include 20-40 parts of non-ionic emulsifier, 2-7 parts of ionic emulsifier, 2-7 parts of ammonium sulfate, 700-900 parts of water, 550-750 parts of butyl acrylate, 60-80 parts of methyl methacrylate, 100-200 parts of a-ethylhexyl acrylate, 20-40 parts of acrylic acid, 0.1-0.5 parts of nano sepiolite, 1-5 parts of silane coupling agent, and 0.5-1.5 parts of isopropyl triisostearyl titanate.

[0027] Specifically in this example, the raw materials used (by weight) include 20 parts of nonionic emulsifier, 2 parts of ionic emulsifier, 2 parts of ammonium persulfate, 700 parts of water, 550 parts of butyl acrylate, methacrylic acid 60 parts of methyl ester, 100 parts of a-ethylhexyl acrylate, 20 parts of acrylic acid, 0.1 part of nano sepiolite, 1 part of silane coupling agent, 0.5 part of isopropyl triisostearyl titanate.

[0028...

Embodiment 2

[0036] The invention provides a reusable emulsion-type acrylate pressure-sensitive adhesive for peeling and sticking. The raw materials used (by weight) include 20-40 parts of non-ionic emulsifier, 2-7 parts of ionic emulsifier, 2-7 parts of ammonium sulfate, 700-900 parts of water, 550-750 parts of butyl acrylate, 60-80 parts of methyl methacrylate, 100-200 parts of a-ethylhexyl acrylate, 20-40 parts of acrylic acid, 0.1-0.5 parts of nano sepiolite, 1-5 parts of silane coupling agent, and 0.5-1.5 parts of isopropyl triisostearyl titanate.

[0037] Specifically in this example, the raw materials used (by weight) include 30 parts of nonionic emulsifier, 5 parts of ionic emulsifier, 5 parts of ammonium persulfate, 800 parts of water, 650 parts of butyl acrylate, methacrylic acid 70 parts of methyl ester, 150 parts of a-ethylhexyl acrylate, 30 parts of acrylic acid, 0.3 parts of nano sepiolite, 3 parts of silane coupling agent, and 1 part of isopropyl triisostearyl titanate.

[...

Embodiment 3

[0046] The invention provides a reusable emulsion-type acrylate pressure-sensitive adhesive for peeling and sticking. The raw materials used (by weight) include 20-40 parts of non-ionic emulsifier, 2-7 parts of ionic emulsifier, 2-7 parts of ammonium sulfate, 700-900 parts of water, 550-750 parts of butyl acrylate, 60-80 parts of methyl methacrylate, 100-200 parts of a-ethylhexyl acrylate, 20-40 parts of acrylic acid, 0.1-0.5 parts of nano sepiolite, 1-5 parts of silane coupling agent, and 0.5-1.5 parts of isopropyl triisostearyl titanate.

[0047] Specifically in this example, the raw materials used (by weight) include 40 parts of nonionic emulsifier, 7 parts of ionic emulsifier, 7 parts of ammonium persulfate, 900 parts of water, 750 parts of butyl acrylate, methacrylic acid 80 parts of methyl ester, 200 parts of a-ethylhexyl acrylate, 40 parts of acrylic acid, 0.5 parts of nano sepiolite, 5 parts of silane coupling agent, and 1.5 parts of isopropyl triisostearyl titanate. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com