Method and system for producing modified pitch and carbon black oil from coal tar

A technology for modifying asphalt and carbon black oil, applied in the field of coal tar distillation, which can solve the problems of high fuel energy consumption and high cost, and achieve the effects of reducing cost, improving quality and reducing use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

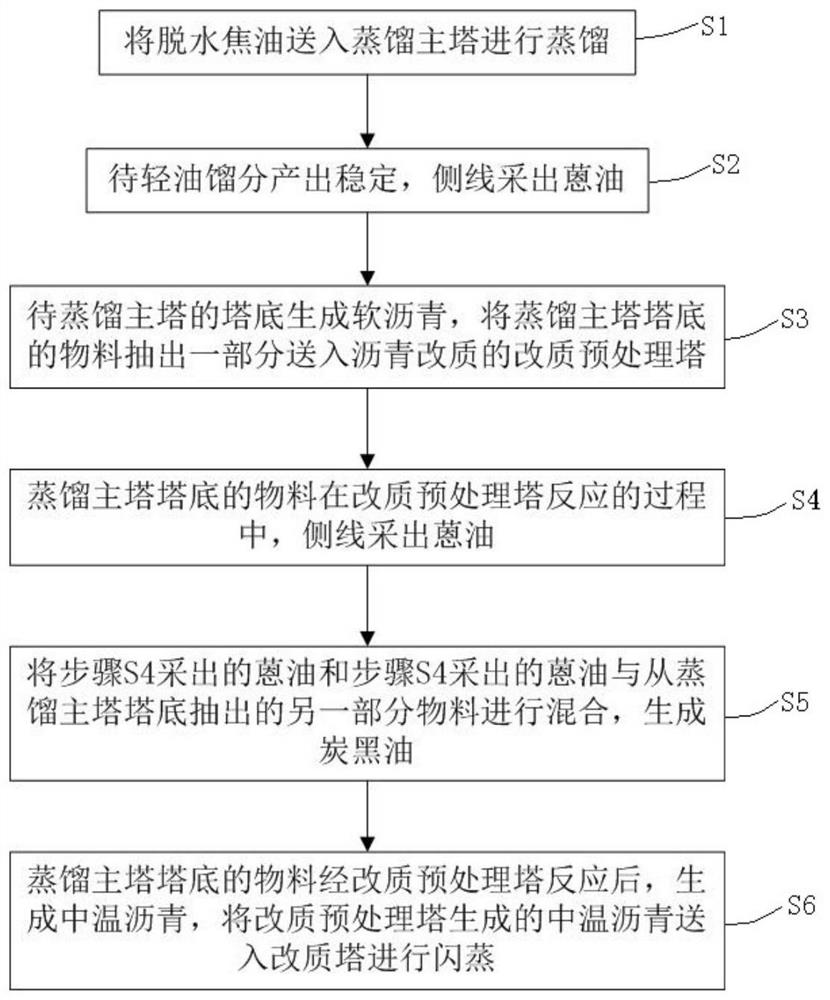

[0032] Such as figure 1 As shown, a kind of coal tar production method of modified pitch and carbon black oil of the preferred embodiment of the embodiments of the present invention comprises the following steps:

[0033] S1, sending the dehydrated tar into the distillation main tower for distillation;

[0034] S2. When the output of light oil fraction is stable, anthracene oil is produced in the side line;

[0035] S3. The bottom of the distillation main tower is to generate soft asphalt, and a part of the material at the bottom of the distillation main tower is taken out and sent to a modified pretreatment tower for asphalt modification;

[0036] S4. During the reaction process of the reforming pretreatment tower, anthracene oil is extracted from the side line of the material at the bottom of the distillation main tower;

[0037] S5, the anthracene oil produced in step S4 and the anthracene oil produced in step S4 are mixed with another part of the material extracted from ...

Embodiment 2

[0042] The difference between this embodiment and Embodiment 1 is that, on the basis of Embodiment 1, step S1 is further described in this embodiment.

[0043] In this embodiment, in step S1, the dehydrated tar is subjected to vacuum distillation in the distillation main column. Vacuum distillation is used to make the internal environment of the distillation main tower a negative pressure, which can reduce the boiling point of the material in the distillation main tower, so that the material can reach a higher temperature while consuming equal fuel energy, and precipitate light oil fractions. The consumption of fuel and energy is reduced, and the cost is reduced. In addition, since the distillation main tower is operated under negative pressure, the distillation temperature is reduced, and the coking of the tube furnace is reduced; and the decompression operation can improve the operating environment and is beneficial to environmental protection.

[0044] Specifically, when th...

Embodiment 3

[0047] The difference between this embodiment and Embodiment 2 is that, on the basis of Embodiment 2, this embodiment further describes step S1.

[0048] In step S1 of this embodiment, the raw tar is sent to the dehydration tower for dehydration and preheating to generate dehydrated tar. During the process of dehydration and preheating of the raw tar in the dehydration tower, light oil fractions are extracted from the side line of the dehydration tower. The raw tar becomes dehydrated tar after heat treatment. During the heat treatment, the raw tar will heat up to remove water and light oil fractions. The light oil fractions extracted from the side line can reduce the light components in the dehydrated tar entering the distillation main tower, making the dehydrated tar The softening point of the dehydrated tar is lowered, which makes it easier to heat up after the dehydrated tar enters the distillation main tower, which can reduce the fuel energy consumed.

[0049] The other st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com