A kind of multilayer composite solar cell back sheet film and preparation method thereof

A solar cell and multi-layer composite technology, which is applied in coatings, circuits, photovoltaic power generation, etc., can solve the problems of poor consistency and easy cracking of solar cell backplane films, achieve excellent antibacterial and flame retardant properties, and meet life requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The multi-layer composite solar cell back sheet film of this embodiment includes an intermediate PET base film and a first coating layer and a second coating layer respectively disposed on the upper surface and the lower surface of the PET base film, the second coating layer It is composed of the following raw materials in parts by weight: 40 parts of polytetrafluoroethylene resin, 25 parts of modified epoxy resin, 5 parts of fluorosilicon modified acrylic resin, 1 part of nanometer titanium dioxide and 3 parts of polyethylene glycol.

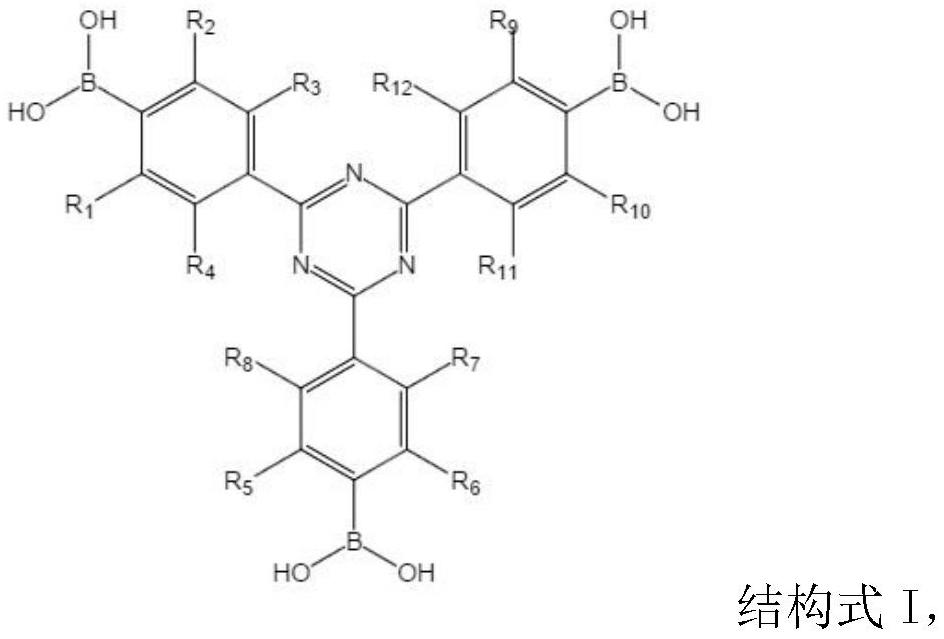

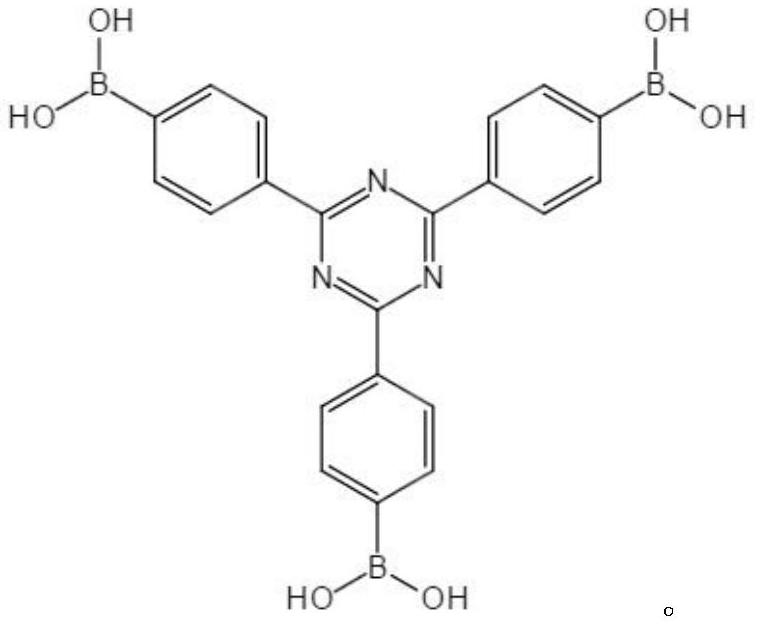

[0025] The first coating is composed of the following raw materials by weight: 40 parts of polytetrafluoroethylene resin, 15 parts of modified epoxy resin, 8 parts of Ag-MOFs material, 1.5 parts of nano inorganic filler, 3 parts of dodecyl Sodium sulfate, 1 part deionized water, 5 parts n-hexane, and 0.1 part fluorine-containing silane coupling agent.

[0026] The modified epoxy resin is polyethylene glycol diglycidyl ether epoxy resin, ...

Embodiment 2

[0035] The multi-layer composite solar cell back sheet film of this embodiment includes an intermediate PET base film and a first coating layer and a second coating layer respectively disposed on the upper surface and the lower surface of the PET base film, the second coating layer It is composed of the following raw materials in parts by weight: 60 parts of polytetrafluoroethylene resin, 35 parts of modified epoxy resin, 10 parts of fluorosilicon modified acrylic resin, 3 parts of nanometer titanium dioxide and 5 parts of polyethylene glycol.

[0036] The first coating is composed of the following raw materials by weight: 50 parts of polytetrafluoroethylene resin, 20 parts of modified epoxy resin, 12 parts of Ag-MOFs material, 1.7 parts of nano inorganic filler, 6 parts of dodecyl Sodium sulfate, 3 parts deionized water, 10 parts n-hexane, and 0.2 part fluorine-containing silane coupling agent.

[0037] The modified epoxy resin is sorbitan polyglycidyl ether epoxy resin. Its...

Embodiment 3

[0044] The multi-layer composite solar cell back sheet film of this embodiment includes an intermediate PET base film and a first coating layer and a second coating layer respectively disposed on the upper surface and the lower surface of the PET base film, the second coating layer It is composed of the following raw materials in parts by weight: 80 parts of polytetrafluoroethylene resin, 45 parts of modified epoxy resin, 15 parts of fluorosilicon modified acrylic resin, 5 parts of nanometer titanium dioxide and 8 parts of polyethylene glycol.

[0045] The first coating is composed of the following raw materials by weight: 60 parts of polytetrafluoroethylene resin, 25 parts of modified epoxy resin, 15 parts of Ag-MOFs material, 1.8 parts of nano inorganic filler, 8 parts of dodecyl Sodium sulfate, 5 parts deionized water, 15 parts n-hexane, and 0.3 part fluorine-containing silane coupling agent.

[0046] The modified epoxy resin is polyethylene glycol diglycidyl ether epoxy re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com