Preparation method of p-nitrophenylacetone

A technology of nitropropiophenone and p-nitrophenylacetic acid, which is applied in the field of preparation of p-nitropropiophenone, can solve problems affecting product quality, difficult to remove by-product impurities, cumbersome purchase and storage procedures, etc., and achieve industrial production , the effect of good purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

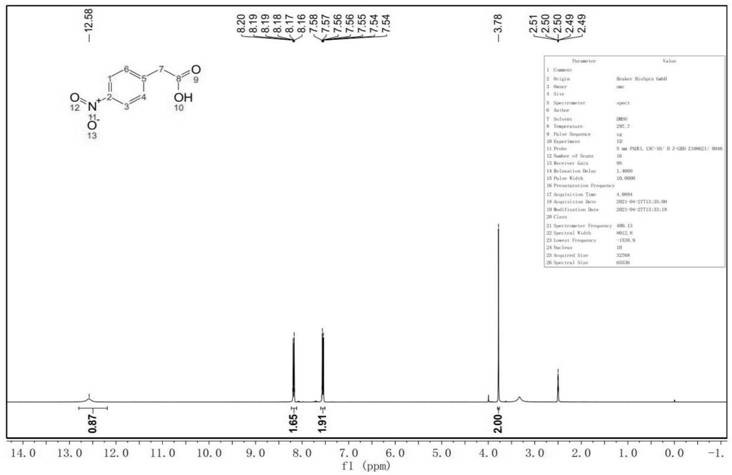

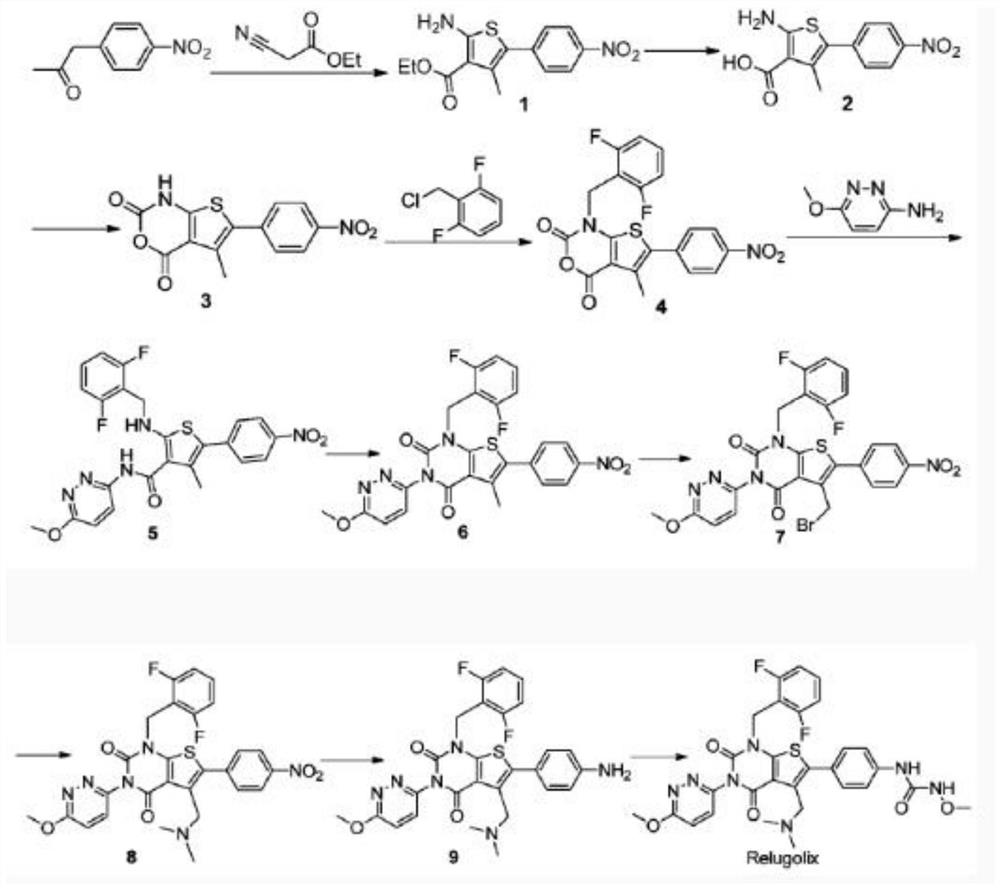

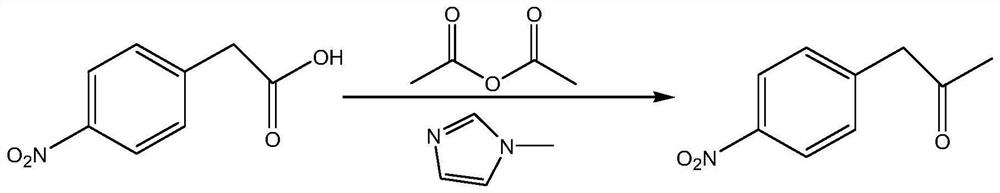

[0033] A kind of preparation method of p-nitropropiophenone, its synthetic route comprises:

[0034]

[0035] Adopt cheap and easy-to-get phenylacetonitrile as starting raw material, obtain p-nitropropiophenone through nitration, hydrolysis, acid chloride, condensation, deacidification, comprising the following steps:

[0036] S1. Nitration: Under the conditions of participation of nitrating agent and dehydrating agent, phenylacetonitrile is nitrated at 15-20°C. The nitrating agent is nitric acid with a concentration of 60-68%, and the catalyst is concentrated sulfuric acid. Phenylacetonitrile, nitrating agent And the molar ratio of the catalyst is 1:1.1-1.2:3.0-5.0;

[0037] S2. Hydrolysis: Complete the hydrolysis process at 100-105°C, precipitate and wash the solid, and obtain p-nitrophenylacetic acid crystals after recrystallization. The solvent used in the recrystallization process includes ethanol and deionized water. The amount of solvent used For 2 times the amount ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com