Fireproof explosion-proof water-based environment-friendly coating for automobile engine compartment

A technology for engine compartments and environmentally friendly coatings, applied in the direction of fire-resistant coatings, anti-corrosion coatings, coatings, etc., can solve problems such as waste of resources, poor coating performance, and lack of solubility, and achieve enhanced heat resistance and wear-resistant fire resistance , the effect of good fire and explosion-proof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the above-mentioned automotive engine cabin fire explosion-proof water-proof coating includes the following steps: adding the leveling agent, defoamer, dispersant, anti-semers and deionized water to aqueous resin, and stir dispersion uniform, then add water infiltration After the phosphate antifolinous pigment and nano-inorganic pigment, the mixture was grounded evenly, and the mixture was grinded to less than 10 μm, i.e., the automotive engine compartment fire explosion-proof water resistant coating.

[0029] The coating method of the above-mentioned automobile engine compartment fire explosion-proof water-proof coating includes the following steps: spray the coating to the engine compartment, level 10 to 15 min; bake the coated engine compartment at 80 ° C for 35min, bake Placing room temperature and temperature dropped to normal temperature, place 24 to 72 h.

Embodiment 1~ Embodiment 6

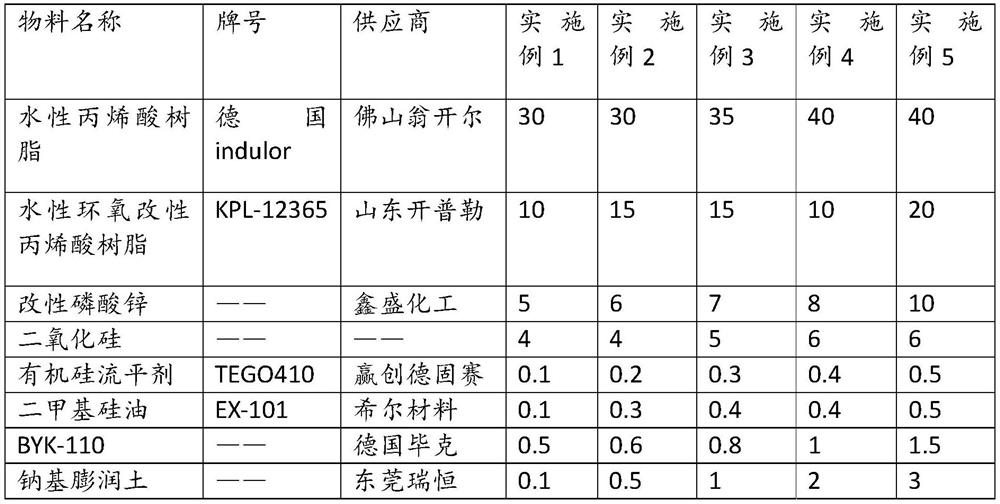

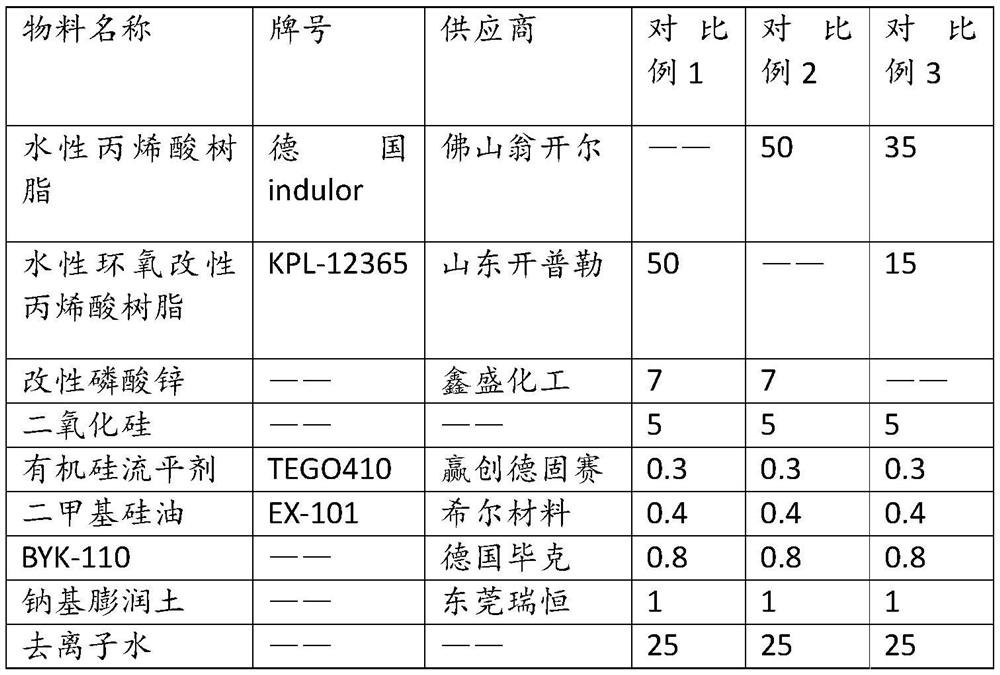

[0031] An automobile engine compartment fire explosion-proof water-proof environmental protection coating, including the following weight materials: See Table 1.

[0032]

[0033]

Embodiment 1~ Embodiment 5

[0034] Examples 1 to Example 5 The preparation method of automobile engine compartment fire explosion-proof water-proof coating, including the following steps:

[0035] According to the amount of formulation of Table 1, the formulation amount of Indulor German aqueous acrylic resin was mixed with aqueous epoxy modified acrylic resin, dispersed at 1200 r / min for 5 min; then the stirring speed was reduced to 800R / min; After dispersion of the rust resistance and nano-inorganic pigment, the aqueous acrylic resin is added to a mixture of aqueous acrylic resin and aqueous epoxy modified acrylic acid resin; stirred is uniform, then add a graft, defoamer, dispersant while stirring. And antitonion. After stirring, it is ground to the fineness of less than 30 μm, that is, the car engine compartment fire explosion-proof waterborne coating is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com