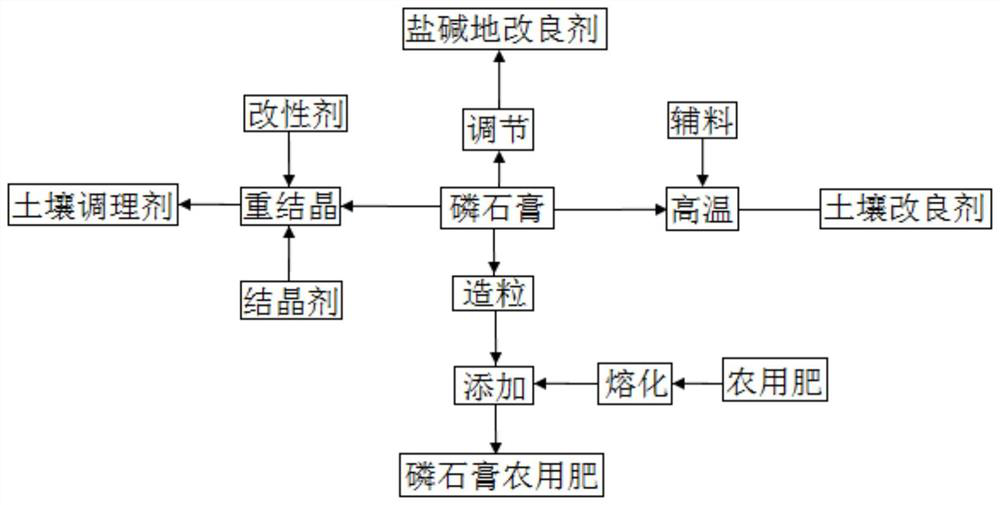

Method for preparing soil conditioner by using ardealite as raw material through high-temperature calcination

A soil conditioner and high-temperature calcination technology, which is applied in the field of solid waste resource utilization, can solve the problems of long processing process, low consumption of phosphogypsum, poor processing effect, etc., and achieves simple process, easy control and operation. , The effect of repairing the status quo of soil compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] After the phosphogypsum collected from the slag dump is crushed through a 50-mesh sieve, it is granulated by adding water, and the particle size is maintained between 2mm-5mm, and then sent into the calciner, protected by a nitrogen atmosphere, and treated at 300°C for 1 hour , to obtain phosphogypsum particles;

[0026] Take phosphogypsum freshly discharged from the wet-process phosphoric acid process as an auxiliary material, add the auxiliary material and phosphogypsum particles at a mass ratio of 0.5:1, and stir at a stirring speed of 100r / min for 30 minutes to obtain the product.

Embodiment 2

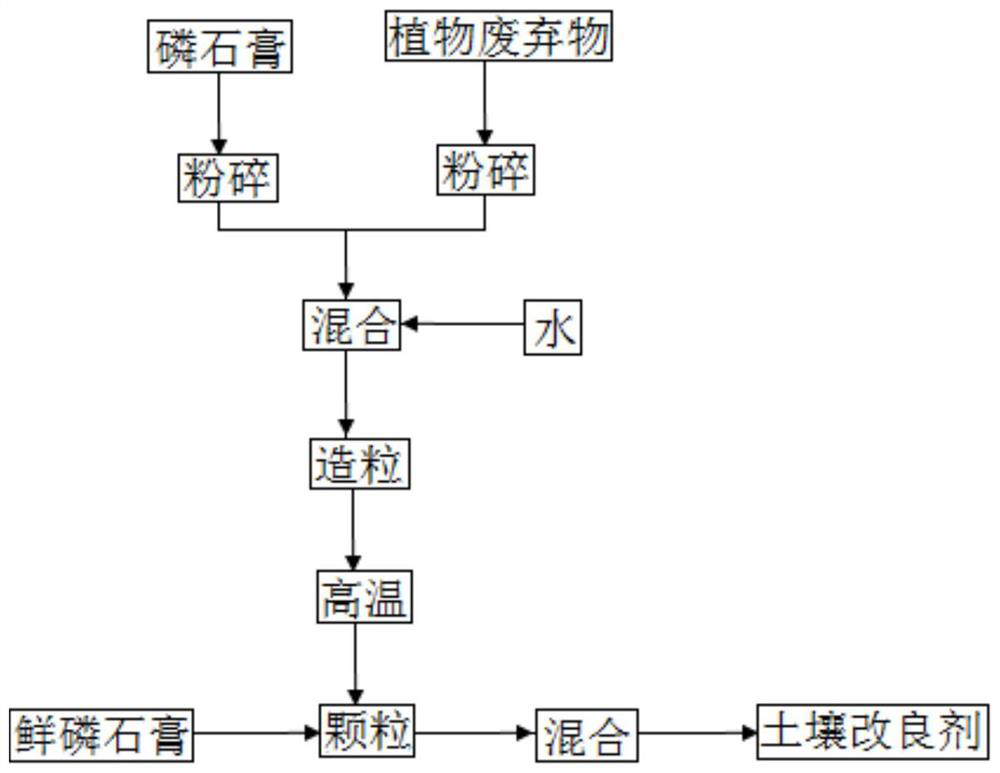

[0028] Such as figure 2 As shown, the phosphogypsum collected from the slag dump was crushed through a 50-mesh sieve to obtain phosphogypsum powder; the plant waste (corn straw) was crushed and passed through a 50-mesh sieve to obtain plant powder; the phosphogypsum powder Mix with plant powder according to the mass ratio of 1:0.01, add water to granulate, and then send it into a calciner, protect it in a nitrogen atmosphere, and treat it at a temperature of 300°C for 1 hour to obtain phosphogypsum particles; other operations are prepared according to the operation method of Example 1, Instantly.

Embodiment 3

[0030] Such as figure 2 As shown, the phosphogypsum collected from the slag dump was crushed through a 50-mesh sieve to obtain phosphogypsum powder; the plant waste (trimmed tea tree dead branches) was crushed and passed through a 50-mesh sieve to obtain plant powder; Mix phosphogypsum powder and plant powder according to the mass ratio of 1:0.05, add water to granulate, and then send it into a calciner, protect it in a nitrogen atmosphere, and treat it at a temperature of 500°C for 1 hour to obtain phosphogypsum granules; other operations are carried out according to the operation method of Example 1. Operation processing preparation, that is.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com