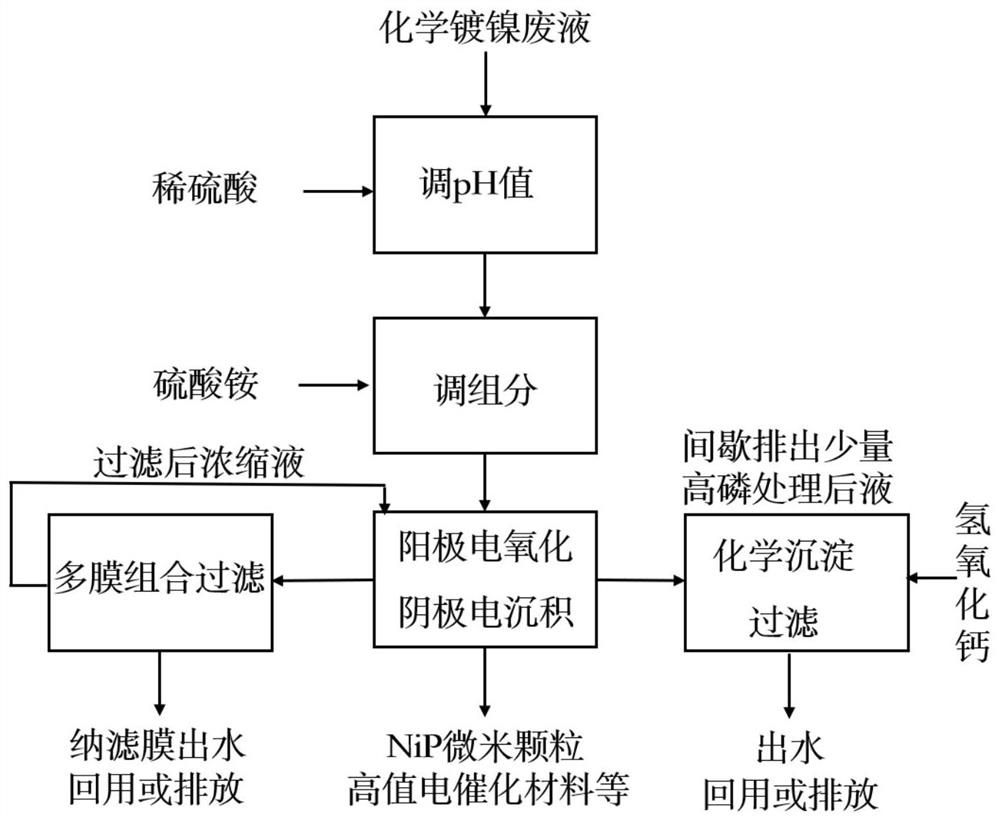

Method for preparing NiP micron particles from chemical nickel plating waste liquid through electrolysis

A technology of electroless nickel plating and micron particles, applied in electrolytic components, electrolytic processes, electrodes, etc., can solve the problems of low added value of waste liquid recovery products, low electrolytic current efficiency, easy pollution of filter membranes, etc., and achieve ion concentration and organic matter The effect of reducing the content, simplifying the stripping process and increasing economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The electroless nickel plating waste solution from a surface treatment company in Hebei was used, and the concentration of nickel ions in the waste solution was 11.7g / L (0.2mol / L). After adding 10L of waste liquid into the adjustment tank, add dilute sulfuric acid to adjust the pH to 1. Add 1320g of ammonium sulfate to the waste liquid and stir to obtain the pretreatment waste liquid whose molar mass concentration of ammonium ion is 2mol / L. The pretreated waste liquid is pumped into the water inlet of the electrochemical treatment tank, and after the waste liquid flows from the water inlet to the water outlet of the electrochemical treatment tank, the DC power supply is turned on, and the electrolytic current density of the cathode plate is set to -2A cm -2 . The waste liquid after cathodic electrolytic treatment enters the tubular ultrafiltration membrane with a filtration operating pressure of 0.5Mpa through the water outlet for filtration. The effluent from the ult...

Embodiment 2

[0045] Change the ammonium sulfate in the embodiment into 132g, and all the other remain unchanged. Then turn on the DC power supply to treat the waste liquid for 30 minutes, and the concentration of phosphite in terms of P element is 201g / L>200g / L. Until white calcium phosphite precipitates out in the solution, no particles are produced by electrolysis on the cathode graphite plate, and no black NiP micron particles appear on the bottom of the cathode mechanism.

Embodiment 3

[0047] The electroless nickel plating waste solution from a surface treatment company in Hebei was used, and the concentration of nickel ions in the waste solution was 11.7g / L (0.2mol / L). After adding 10L waste liquid into the adjustment tank, add dilute sulfuric acid to adjust the pH to 3.5. All the other are the same as in Example 1, and after turning on the DC power supply to treat the waste liquid for 35 minutes, the concentration of phosphite in terms of P element is 202g / L>200g / L. Black NiP micron particles were collected from the bottom of the cathode mechanism, but the amount of the particles was significantly smaller than in Example 1, and there were some black particles produced by electrolysis on the cathode graphite plate. The quality of the effluent after filtration by the roll-type nanofiltration membrane meets the requirements in Table 3 of my country's current electroplating pollutant discharge standard (GB21900-2008): total nickel≤0.1mg / L, total phosphorus≤1mg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com