Highland barley whole grain bread and production method thereof

A whole grain and highland barley technology, applied in the field of highland barley whole grain bread and its preparation, can solve the problems of difficulty in forming highland barley, small specific volume of bread, lack of agglomeration of highland barley flour, etc. The effect of improving taste structure and specific volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

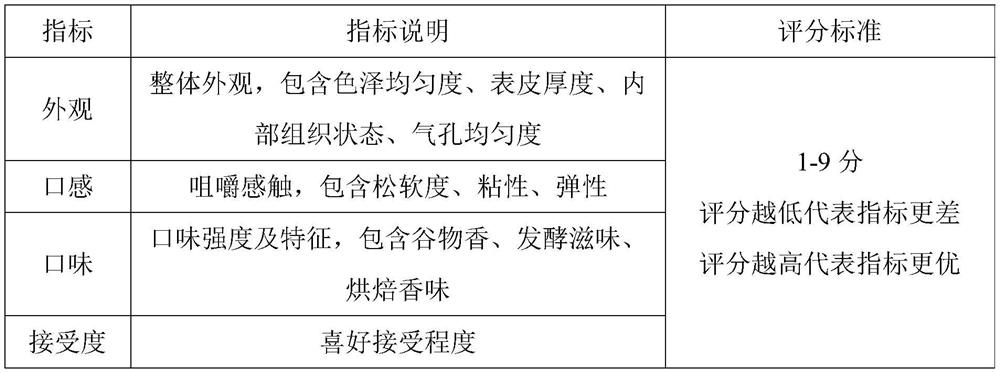

Method used

Image

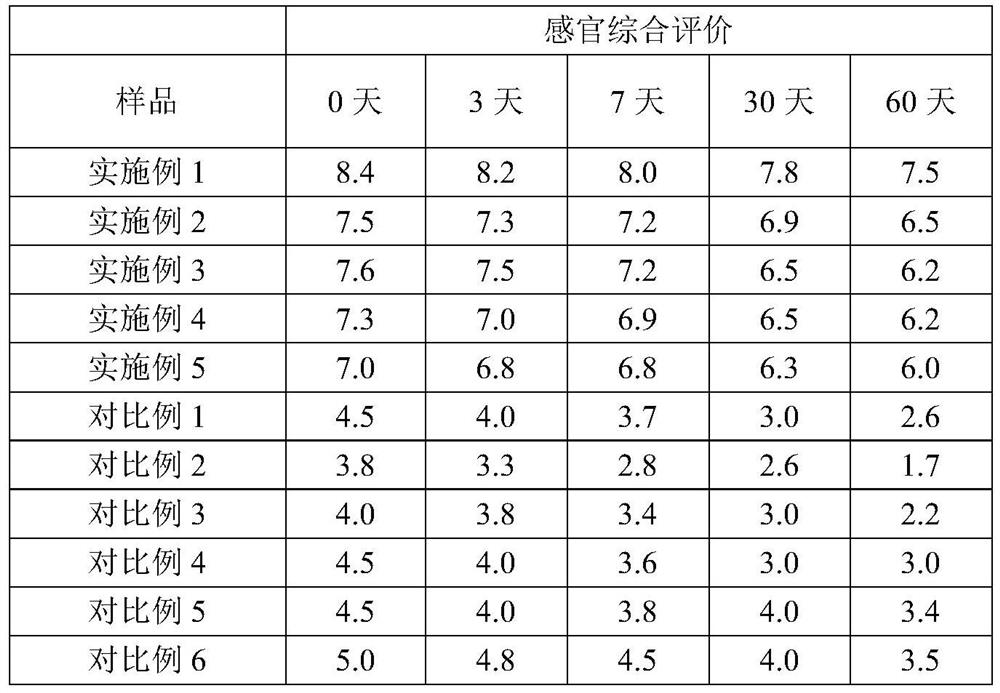

Examples

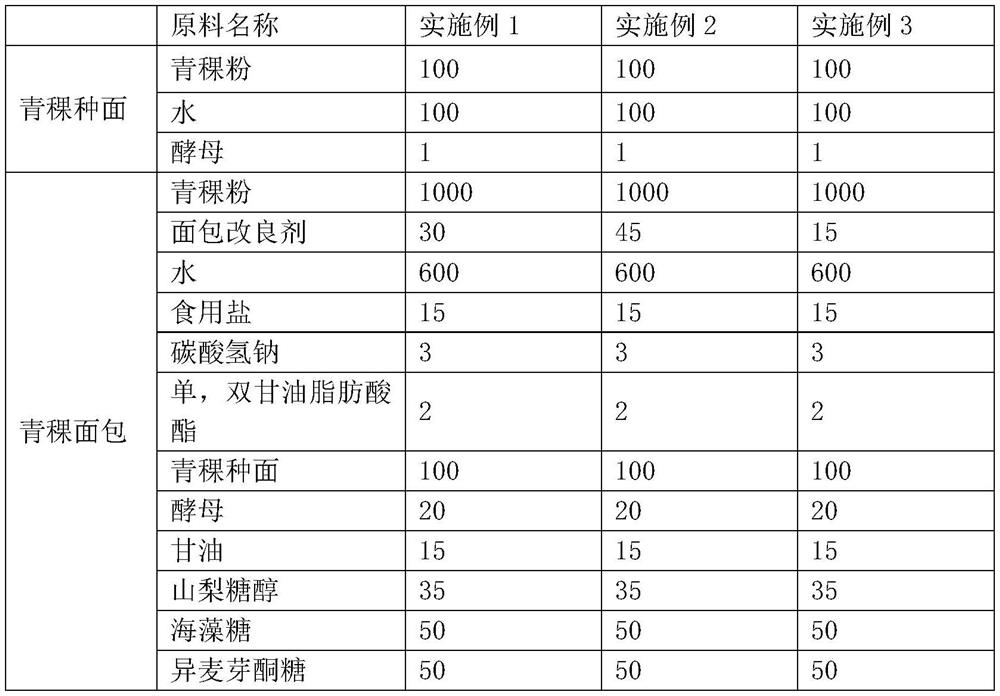

Embodiment 1

[0036] According to the recipe of Example 1 in Table 2, the highland barley whole grain bread was made according to the following steps.

[0037] (1) Preparation of highland barley flour: Soak the whole highland barley for 6.0 hours (<45°C), fully absorb water, and perform steam explosion: pressure 0.8MPa, time 3min; drying condition: 55°C, 20h. Finally pulverize to highland barley flour 80-100 order;

[0038] (2) Preparation of highland barley flour: mix highland barley powder: water at a mass ratio of 1:1, add yeast in an amount of 1% of the highland barley powder, and carry out low-temperature fermentation. The fermentation time is 16±2h, and the fermentation temperature is 0-4°C (to twice as large);

[0039] (3) Dough preparation: add highland barley flour, highland barley powder, bread improver, water and other auxiliary materials in sequence according to the formula, and beat to form a film;

[0040] (4) Segmentation: the dough whipped into a film in step (3) is divide...

Embodiment 2

[0045] The method for referring to Example 1 prepares highland barley whole grain bread, the difference is that the parameter conditions of highland barley whole grain bread are adjusted according to the formula of Example 2 in Table 2, and other conditions are the same as in Example 1.

Embodiment 3

[0047] The method for referring to Example 1 prepares highland barley whole grain bread, the difference is that the parameter conditions of highland barley whole grain bread are adjusted according to the formula of Example 3 in Table 2, and other conditions are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com