Graphene oxide surface arsenic-antimony double-imprinted polymer capable of being magnetically separated in underground medium and preparation method thereof

A graphene surface and imprinted polymer technology, applied in the direction of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve problems such as arsenic and antimony pollution, reduce agglomeration and facilitate elution and recombination, good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

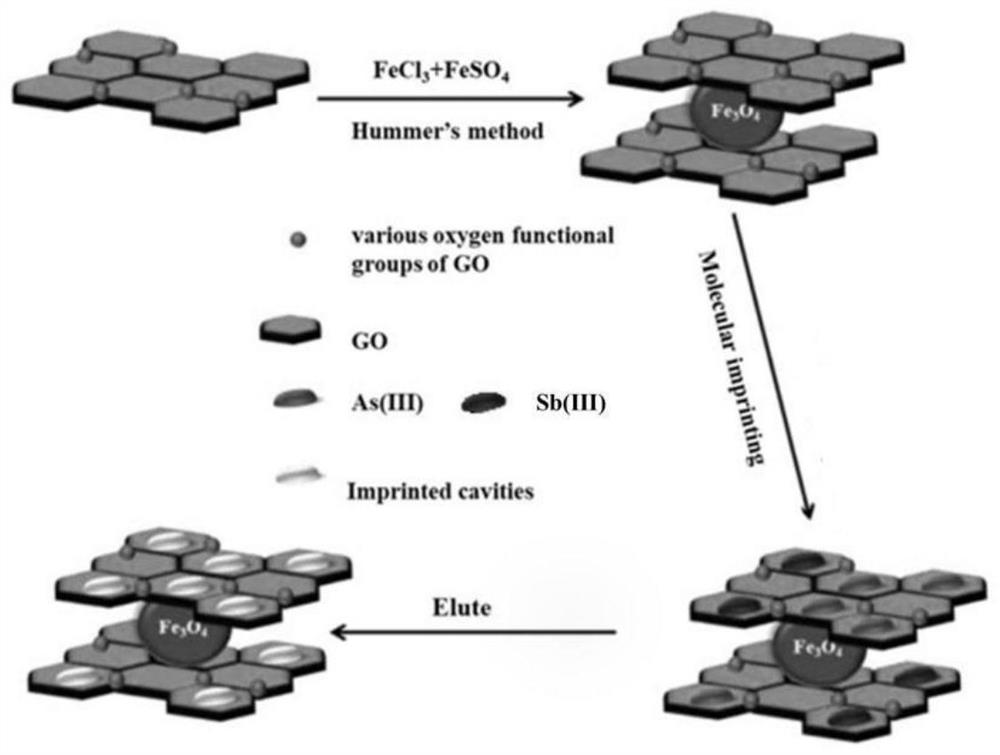

[0040] The preparation method of the arsenic-antimony double imprinted polymer on the surface of graphene oxide that can be magnetically separated in the above-mentioned underground medium comprises the following steps:

[0041] A. Ultrasonic disperse 0.3-0.86g of GO into 0.45L of ultrapure water until GO is evenly dispersed in the ultrapure water to stop, the time is about 1 hour, and then a stable GO suspension is obtained;

[0042] B. Add 2.916g of FeCl 3 and 2.502 g of FeSO 4 ·7H 2 O was dissolved in 50ml of deionized water, and then slowly poured into the suspension of A at room temperature. In order to mix evenly with A, pre-stirring was required for 40 minutes;

[0043] C. Increase the temperature of the solution in step B to 60°C, slowly add ammonia water dropwise to the solution under anaerobic conditions by in-situ precipitation method, so that the pH in the solution is greater than 10, and then continue to increase the temperature to 90°C and continue Stir for 4 ...

Embodiment 1

[0050] A. Ultrasonic disperse 0.3g GO into 450mL of ultrapure water for about 1 hour, and then obtain a stable GO suspension;

[0051] B. Add 2.916g of FeCl 3 and 2.502 g of FeSO 4 ·7H 2 O was dissolved in 50ml of deionized water, then slowly poured into the A suspension at room temperature, and mechanically stirred for 40min;

[0052] C. Increase the temperature of the solution in step B to 60°C, slowly add ammonia water dropwise to the solution under nitrogen protection, so that the pH in the solution is greater than 10, then continue to increase the temperature to 90°C and continue stirring for 4 hours;

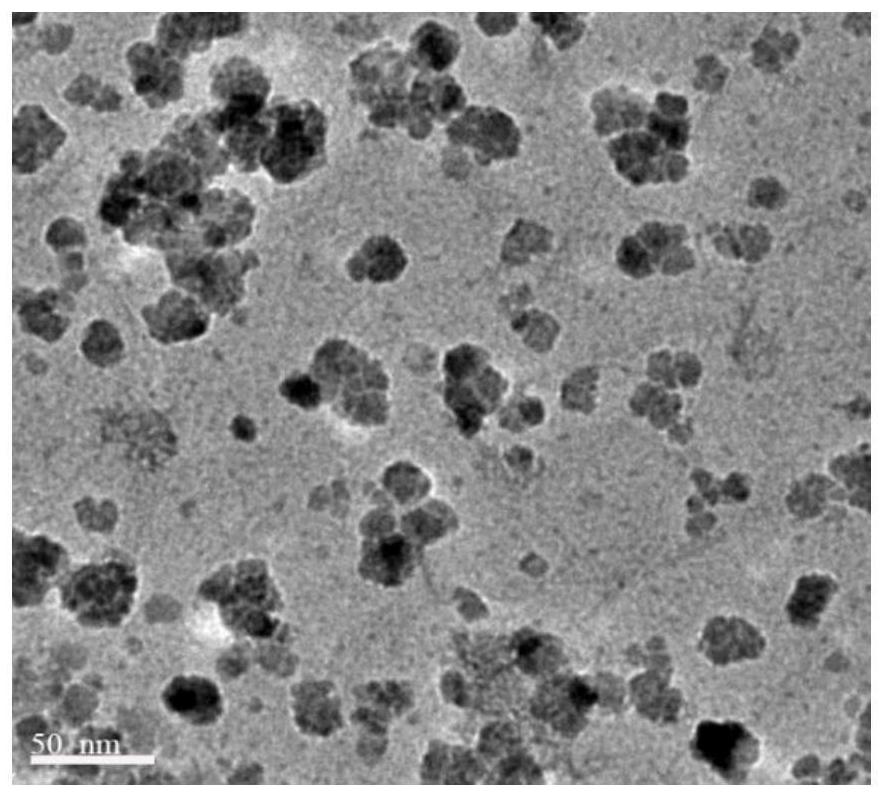

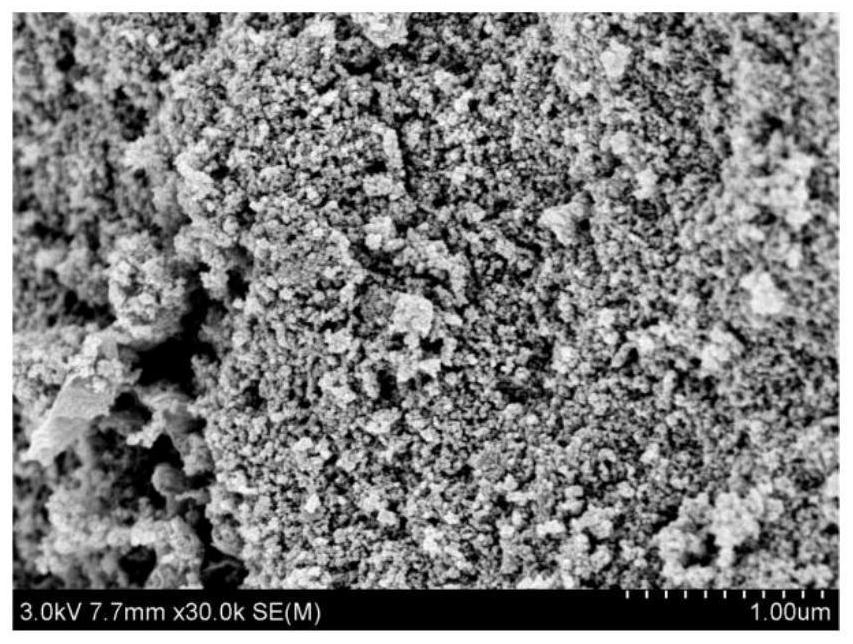

[0053] D. Use a magnet to collect the product in the solution of step C, wash it repeatedly with ethanol and ultrapure water for 3 times, and then put the product in a vacuum drying oven at 60°C to dry to obtain Fe 3 o 4 / GO (MGO) material, where GO and Fe 3 o 4 The mass ratio is 0.14:1.

Embodiment 2

[0055] A. Ultrasonic disperse 0.54g GO into 450mL of ultrapure water for about 1 hour, and then obtain a stable GO suspension;

[0056] B. Add 2.916g of FeCl 3 and 2.502 g of FeSO 4 ·7H 2 O was dissolved in 50ml of deionized water, then slowly poured into the A suspension at room temperature, and mechanically stirred for 40min;

[0057] C. Increase the temperature of the solution in step B to 60°C, slowly add ammonia water dropwise to the solution under nitrogen protection, so that the pH in the solution is greater than 10, then continue to increase the temperature to 90°C and continue stirring for 4 hours;

[0058] D. Use a magnet to collect the product in the solution of step C, wash it repeatedly with ethanol and ultrapure water for 3 times, and then put the product in a vacuum drying oven at 60°C to dry to obtain Fe 3 o 4 / GO (MGO) material, where GO and Fe 3 o 4 The mass ratio is 0.25:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com