Preparation method and application of phthalocyanine-derived functional carbon quantum dot modified CIZS quantum dot composite photocatalyst

A technology of carbon quantum dots and quantum dots, which is applied in the preparation of composite photocatalysts and functional carbon quantum dots modified CIZS quantum dot composite photocatalysts, can solve the problems that the role of CDs has not been clearly proved, and achieve high-efficiency photocatalytic hydrogen production , Facilitate mass production, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

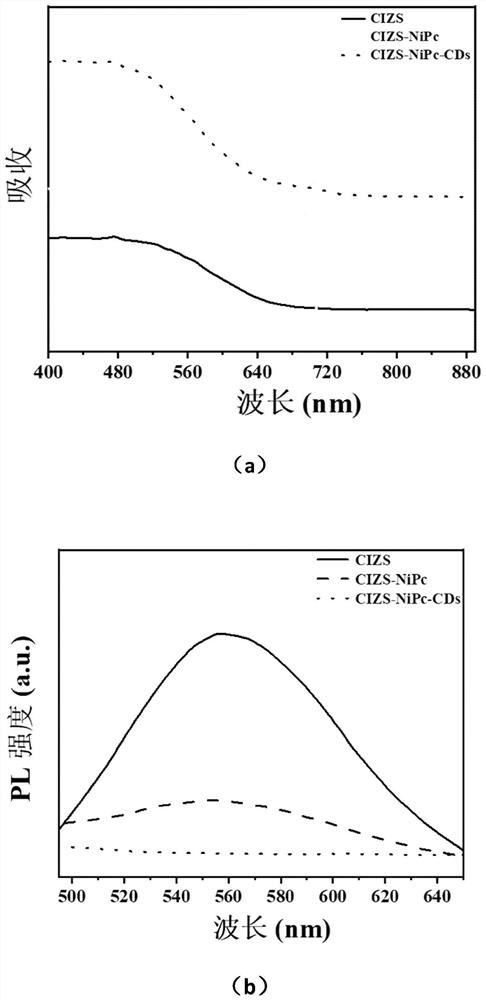

Method used

Image

Examples

Embodiment 1

[0030] (1) Preparation of CDs-NiPc precursor:

[0031] Pipette 100mg of CDs and 4.48mg of nickel phthalocyanine solution into a transparent glass bottle and dilute to 20mL solution. The above solution was hydrothermally reacted in an autoclave at 140°C for 4 hours, and then used in the next step after cooling.

[0032] (2) Preparation of CIZS-CDs-NiPc composite photocatalyst:

[0033] Weigh 19.80mg of CIZS quantum dots and dissolve them in 14.00mL of water, add 0.20mg of CDs-NiPc precursor, stir ultrasonically, and conduct a hydrothermal reaction in an autoclave at 110°C for 4 hours, wash after the reaction to obtain a CIZS-CDs-NiPc composite catalyst of light.

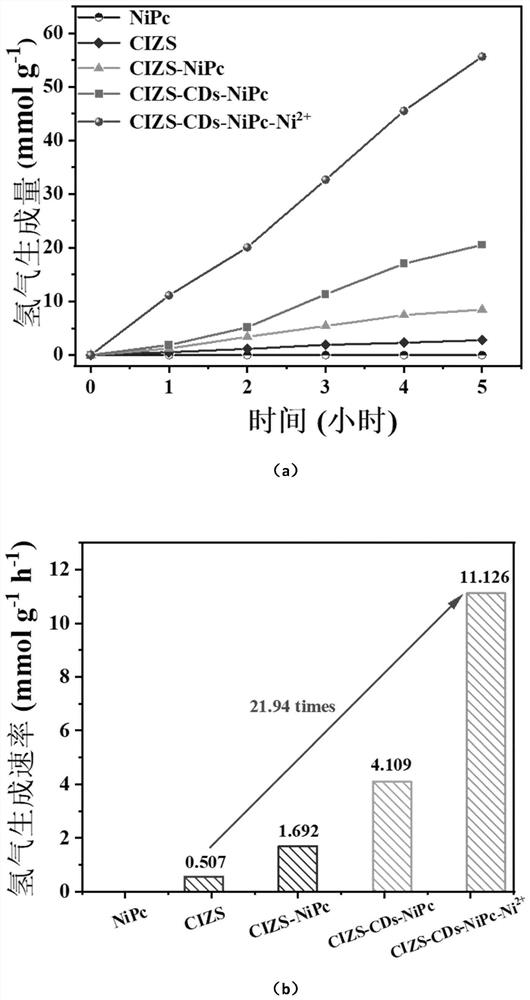

[0034] Take 0.02g of CIZS-CDs-NiPc composite photocatalyst and 0.528g of L-ascorbic acid and add them to the photoreactor. 2 After the gas in the bottle is exhausted. Turn on the customized xenon lamp irradiation under the condition of magnetic stirring, and take samples and analyze every 1h.

[0035] The hydrogen...

Embodiment 2

[0037] (1) Preparation of CDs-NiPc precursor:

[0038] Pipette 104mg of CDs and 4.40mg of nickel phthalocyanine solution into a transparent glass bottle and dilute to 20mL solution. The above solution was hydrothermally reacted in an autoclave at 140°C for 4 hours, and then used in the next step after cooling.

[0039] (2) Preparation of CIZS-CDs-NiPc composite photocatalyst:

[0040]Weigh 19.80mg of CIZS quantum dots and dissolve them in 14.00mL of water, add 0.20mg of CDs-NiPc precursor, stir ultrasonically, and conduct a hydrothermal reaction in an autoclave at 110°C for 4 hours, wash after the reaction to obtain a CIZS-CDs-NiPc composite catalyst of light.

[0041] Take 0.02g of CIZS-CDs-NiPc composite photocatalyst and 0.528g of L-ascorbic acid and add them to the photoreactor. 2 After the gas in the bottle is exhausted. Turn on the customized xenon lamp irradiation under the condition of magnetic stirring, and take samples and analyze every 1h.

[0042] The rate of h...

Embodiment 3

[0044] (1) Preparation of CDs-NiPc precursor:

[0045] Pipette 106mg of CDs and 8.84mg of nickel phthalocyanine solution into a transparent glass bottle and dilute to 20mL solution. The above solution was hydrothermally reacted in an autoclave at 140°C for 4 hours, and then used in the next step after cooling.

[0046] (2) Preparation of CIZS-CDs-NiPc composite photocatalyst:

[0047] Weigh 19.64mg of CIZS quantum dots and dissolve them in 14.10mL of water, add 0.40mg of CDs-NiPc precursor, stir ultrasonically, and react hydrothermally in an autoclave at 110°C for 4 hours, wash after the reaction, and obtain CIZS-CDs-NiPc composite catalyst of light.

[0048] Take 0.02g of CIZS-CDs-NiPc composite photocatalyst and 0.528g of L-ascorbic acid and add them to the photoreactor. 2 After the gas in the bottle is exhausted. Turn on the customized xenon lamp irradiation under the condition of magnetic stirring, and take samples and analyze every 1h.

[0049] The hydrogen production...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com