Quick repair material for anti-freezing and anti-salt-freezing airport cement pavement and preparation method of quick repair material

A repair material and anti-salt-freeze technology, applied in the field of building materials, can solve the problems of anti-freeze, poor anti-salt-freeze performance, high price, secondary damage, etc., and achieve excellent waterproof effect, easy implementation, and excellent anti-freeze effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

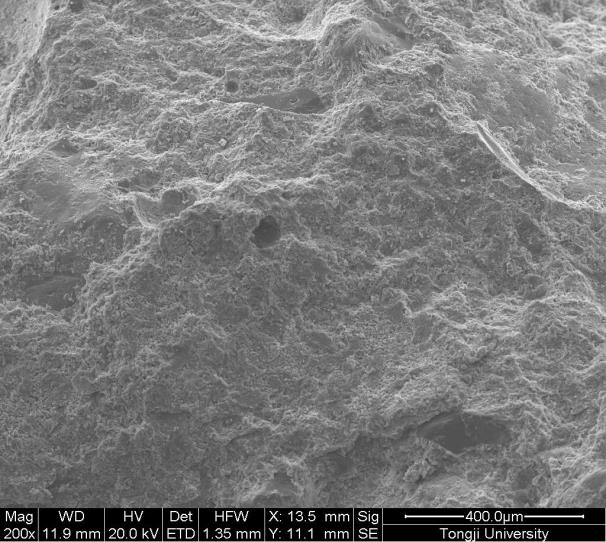

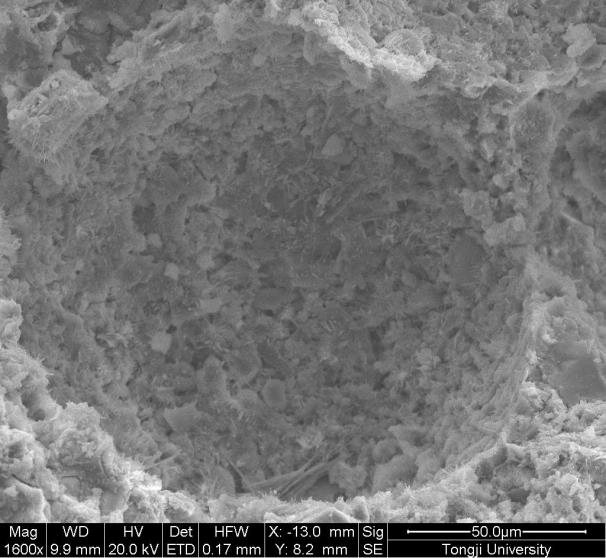

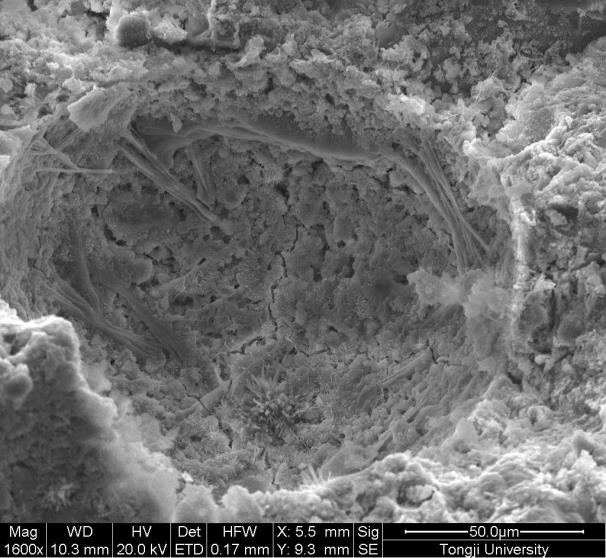

Image

Examples

Embodiment 1

[0043] A quick repair material for frost-resistant and salt-freeze airport cement pavement, which is prepared by the following method:

[0044] (1) Weigh 100 parts by mass of powder and 40 parts by mass of liquid:

[0045]Weigh the powder: Weigh 5 parts of 625 aluminate cement, 16 parts of 525 sulphoaluminate cement, 18 parts of 525 Portland cement, and 7 parts of 200~400 mesh hemihydrate gypsum powder according to the weight fraction required by each raw material , 2 parts of primary fly ash, 2 parts of ultra-fine silica fume of 1000~2000 mesh, 48.26 parts of mixed quartz sand (4.8 parts of 8~10 mesh quartz sand, 33.8 parts of 20~40 mesh quartz sand, 70~140 mesh quartz sand 9.66 parts), 0.3 parts of tartaric acid, 0.02 parts of lithium sulfate, 0.1 part of polycarboxylate superplasticizer powder, 0.1 part of polyether defoamer, 0.3 part of 400 viscosity hydroxypropyl methylcellulose;

[0046] Weigh liquid materials: Weigh 8 parts of silica sol, 12 parts of styrene-butadiene ...

Embodiment 2

[0052] A quick repair material for frost-resistant and salt-freeze airport cement pavement, which is prepared by the following method:

[0053] (1) Weigh 100 parts by mass of powder and 40 parts by mass of liquid:

[0054] Weigh the powder: Weigh 7 parts of 625 aluminate cement, 15 parts of 725 sulfoaluminate cement, 16 parts of 525 Portland cement, and 8 parts of 200~400 mesh hemihydrate gypsum powder according to the weight fraction required by each raw material , 2.5 parts of primary fly ash, 3.5 parts of superfine silica fume of 1000~2000 mesh, 45.26 parts of mixed quartz sand (4.5 parts of 8~10 mesh quartz sand, 31.7 parts of 20~40 mesh quartz sand, 70~140 mesh quartz sand 9.06 parts), retarder (combination of tartaric acid and sodium gluconate) 0.5 parts, lithium carbonate 0.04 parts, polycarboxylate superplasticizer powder 0.25 parts, defoamer (organic silicon defoamer and polyether Combination) 0.2 parts, 400 viscosity hydroxypropyl methylcellulose 0.4 parts;

[0055...

Embodiment 3

[0062] A quick repair material for frost-resistant and salt-freeze airport cement pavement, which is prepared by the following method:

[0063] (1) Weigh 100 parts by mass of powder and 40 parts by mass of liquid:

[0064] Weigh the powder: Weigh 10 parts of 625 aluminate cement, 20 parts of 725 sulfoaluminate cement, 20 parts of 525 Portland cement, and 10 parts of 200~400 mesh hemihydrate gypsum powder according to the weight fraction required by each raw material , 3 parts of primary fly ash, 5 parts of superfine silica fume of 1000~2000 mesh, 50 parts of mixed quartz sand (5 parts of quartz sand of 8~10 mesh, 35 parts of quartz sand of 20~40 mesh, 35 parts of quartz sand of 70~140 mesh 10 parts), retarder (combination of sodium gluconate and citric acid) 1 part, early strength agent (combination of lithium sulfate and lithium carbonate) 0.05 parts, polycarboxylate superplasticizer powder 0.4 parts, defoamer (combination of silicone defoamer and mineral oil defoamer) 0.3 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com