Modified asphalt and preparation method thereof

A technology of modified asphalt and matrix asphalt, used in building components, building insulation materials, buildings, etc., can solve the problems of poor high and low temperature resistance, easy cracking and deformation, etc. Effects of low temperature elongation and high temperature properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

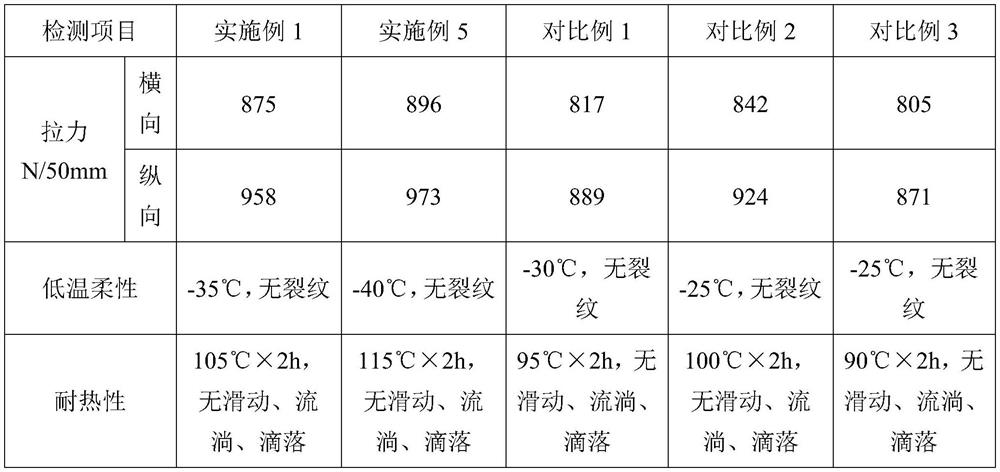

Examples

Embodiment 1

[0033] A modified asphalt, in parts by weight, comprises the following components:

[0034] 35 parts of No. 90 petroleum asphalt, 2 parts of tourmaline powder, 2 parts of nano-montmorillonite, 0.1 part of CA-60 nonionic surfactant, 1 part of GF-6270 dispersion stabilizer, 3 parts of SBS1302, 2 parts of epoxy resin, engine oil 6 parts, 5 parts of tire rubber powder, 25 parts of talcum powder, 0.5 parts of sodium stearoyl lactylate, 1 part of trimethylolpropane trimethacrylate;

[0035] Among them, the fineness of rubber powder is ≥60 mesh; the fineness of talc powder is ≥200 mesh, the particle size of nano-montmorillonite is 100-200nm, the flash point of engine oil is ≥220°C, the tourmaline powder is 200 mesh, and negative ions are released Quantity 5000pcs / cm 3 ;

[0036] Its preparation method comprises the following steps:

[0037] S1, prepare materials according to the formula of the above-mentioned modified asphalt;

[0038] S2. Mix No. 90 petroleum asphalt and engine ...

Embodiment 2

[0042] A modified asphalt, in parts by weight, comprises the following components:

[0043] 50 parts of No. 90 petroleum asphalt, 5 parts of tourmaline powder, 5 parts of nano-plastite, 0.5 parts of PEG6000 non-ionic surfactant, 3 parts of WSG-104H dispersion stabilizer, 8 parts of SBS1401, 6 parts of terpene resin, 12 parts of heavy oil , 15 parts of tire rubber powder, 40 parts of talcum powder, 1 part of sodium stearoyl lactylate, 1.5 parts of trimethylolpropane trimethacrylate;

[0044] Among them, the fineness of the rubber powder is ≥60 mesh; the fineness of the talc powder is ≥200 mesh, the particle size of the nano-calcined stone is 100-200nm, the flash point of the heavy oil is ≥220°C, the tourmaline powder is 500 mesh, and the anion release Quantity 5000pcs / cm 3 ;;

[0045] Its preparation method comprises the following steps:

[0046] S1, prepare materials according to the formula of the above-mentioned modified asphalt;

[0047] S2. Mix No. 90 petroleum asphalt...

Embodiment 3

[0051] A modified asphalt, in parts by weight, comprises the following components:

[0052]40 parts of No. 90 petroleum asphalt, 3 parts of tourmaline powder, 3 parts of nano-silica, 0.2 parts of Abex-2535 nonionic surfactant, 2 parts of GF-6270 dispersion stabilizer, 5 parts of SEBS604T, 4 parts of petroleum resin, softening oil 8 parts, 10 parts of tire rubber powder, 30 parts of talcum powder, 0.8 parts of sodium stearoyl lactylate, 1.2 parts of trimethylolpropane trimethacrylate;

[0053] Among them, the fineness of tire rubber powder is ≥60 mesh; the fineness of talc powder is ≥200 mesh, the particle size of nano-silica is 100-200nm, the flash point of heavy oil is ≥220°C, tourmaline powder is 500 mesh, Release 5000 / cm 3 ;

[0054] Its preparation method comprises the following steps:

[0055] S1, prepare materials according to the formula of the above-mentioned modified asphalt;

[0056] S2. Mix No. 90 petroleum asphalt and softened oil evenly, heat up to 180°C, add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com