Hemp elastic antibacterial denim fabric and processing method thereof

A technology of denim fabric and processing method, applied in textile, fabric, textile and papermaking, etc., can solve the problems of poor elasticity, poor antiseptic and bacteriostatic effect, and poor moisture absorption effect, and achieves improved roughness, excellent antibacterial property, and moisture absorption. Quick release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

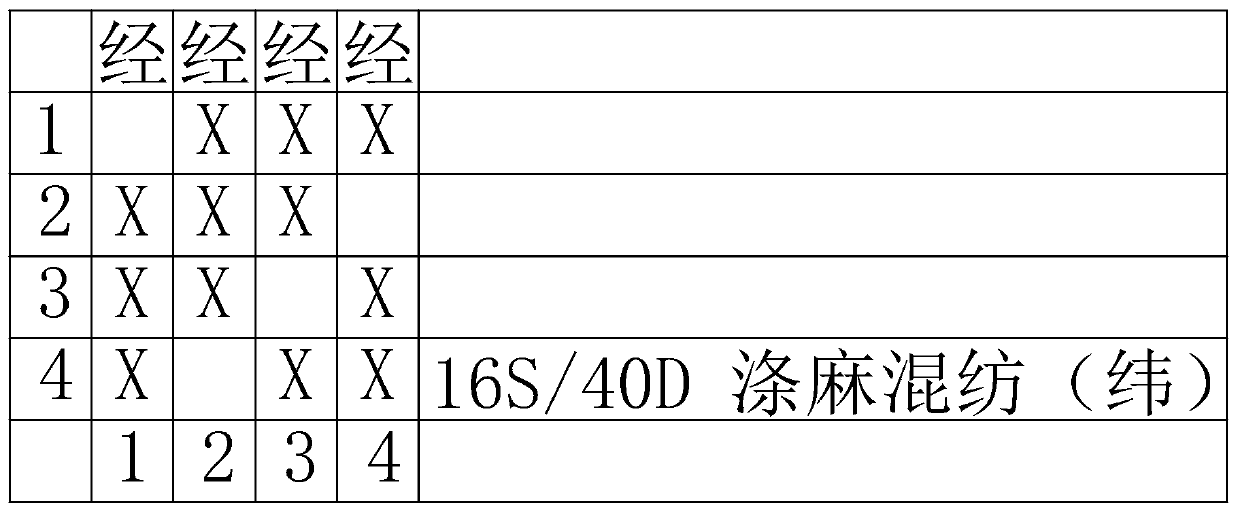

[0018] Such as figure 1 As shown, a hemp elastic antibacterial denim fabric according to the present invention comprises a fabric interwoven with warp yarns of one system and weft yarns of another system. , located in the surface layer in the fabric, the warp and weft yarns are composed of 72% cotton yarn, 19% recycled polyester, 8% hemp fiber, and 1% spandex elastic yarn by weight percentage, and the cotton yarn cotton is white cotton, Fiber length 80% is in 25-35mm, and the use of described cotton is longer than the length requirement of fine-staple cotton 23-33mm, and the fiber diameter width of cotton fiber fineness aspect is 18-25um. The hemp elastic antibacterial denim fabric of the present invention adopts 72% of cotton yarn, 19% of recycled polyester, 8% of hemp fiber, and 1% of spandex elastic yarn. Hemp fiber is a natural plant fiber, which has antiseptic and antibacterial properties, fast moisture absorption and moisture release, and drape Good, no itching and othe...

Embodiment 2

[0022] A processing method of hemp elastic antibacterial denim fabric described in embodiment one, comprises the steps:

[0023] (1) Prepare 72% cotton yarn by weight, 19% recycled polyester, 8% hemp fiber, 1% spandex elastic yarn and make embryo yarn;

[0024] (2) Carry out warping treatment, so that the warping speed is 250m / min; the warping quality requires uniform tension, arrangement, and winding of the sheet yarn, and the middle speed, low tension, and tension are divided into four areas and three layers; at the same time, the yarn is cleaned regularly The thread channel prevents the return pattern from being brought into the warp beam, so as to ensure the quality and production efficiency of the warp beam;

[0025] (3) Carry out sizing and dyeing treatment, the solid content of sizing yarn must reach 11%, the sizing rate is 9.5%-10.5%, the moisture regain rate is 6%-7%, and the elongation rate is 1%-1.5%; the sizing and dyeing includes sizing , Dyeing, dyeing first, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com