A kind of preparation method of nano energy storage material and lithium ion battery containing it

A technology for lithium ion batteries and energy storage materials, which is applied in the field of preparation of lithium ion batteries and nano-silicon energy storage materials, can solve the problems of limited capacity improvement, lithium ion consumption, accelerated capacity, etc., and achieves good stretch recovery and buffer volume. Shrinkage changes and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

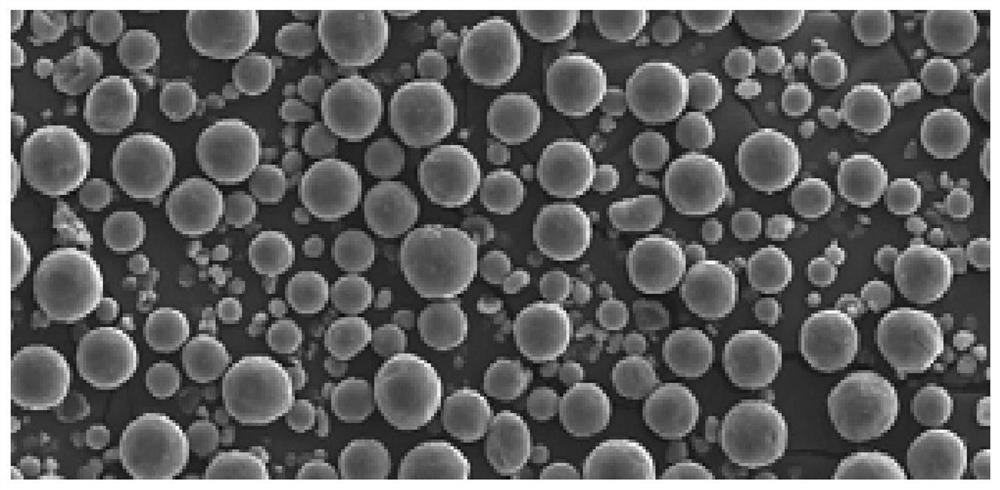

Image

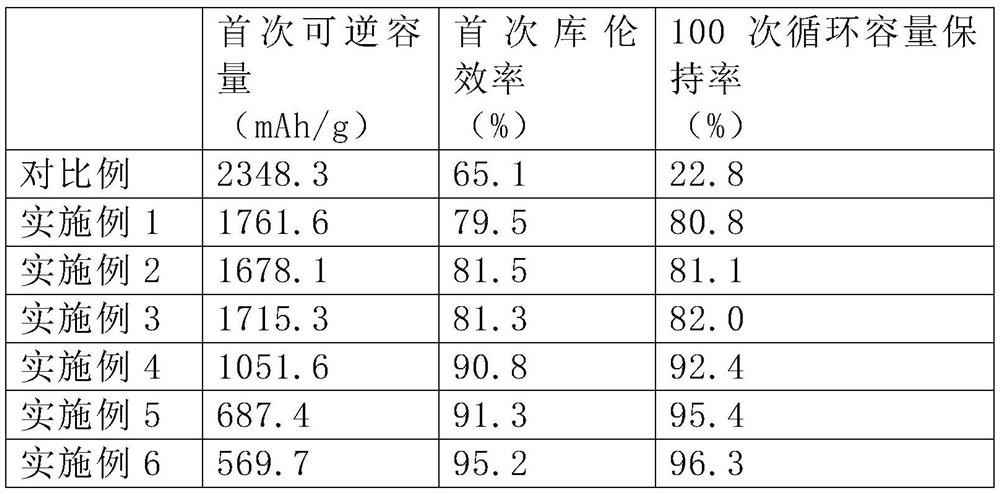

Examples

Embodiment 1

[0031] Step 1. Select 100 parts of silicon particles with a D50 particle size of 300nm and 1.5 parts of siloxane coupling agent γ-aminopropyltriethoxysilane KH550, and after mechanical mixing, ultrasonically disperse them in absolute ethanol. Ultrasound at ℃ for 2 hours to carry out surface grafting treatment, filter and dry for later use;

[0032] Step 2. Add 8 parts of hexadecyltrimethoxysilane to 100 parts of aqueous solution at 30°C for 1 hour for hydrolysis, add 5 parts of the product from Step 1 as a nucleating substance and disperse evenly, heat up to 60°C, and the pH value is Polymerization coating of siloxane emulsion was carried out under weakly acidic conditions of 6, and the reaction time was 1 hour. At this time, the pH value was adjusted to 10, and then 10 parts of hexadecyltrimethoxysilane, 2 parts of tetrabutyl silicate The ester continued to react for 3 hours, and was filtered and dried to obtain D50 as a microsphere substance of 1.8 microns;

[0033] Step 3....

Embodiment 2

[0035] Step 1. Select 100 parts of silicon particles with a D50 particle size of 150nm and 2 parts of siloxane coupling agent γ-glycidyl ether propyl trimethoxysilane KH560, and disperse them in ethylene glycol by ultrasonic after mechanical mixing. Ultrasonic at 40°C for 2 hours to carry out surface grafting treatment, filter and dry for later use;

[0036] Step 2. Add 15 parts of dimethyldimethoxysilane to 100 parts of aqueous solution and hydrolyze at 30°C for 0.5 hours, add 8 parts of the product from Step 1 as a nucleating substance and disperse evenly, heat up to 50°C, and the pH value is Polymerization coating of siloxane emulsion was carried out under the neutral condition of 7, and the reaction time was 1 hour. At this time, the pH value was adjusted to 9, and 10 parts of phenyltrimethoxysilane was added to continue the reaction for 3 hours, filtered and dried to obtain D50 2.5 micron microspheres;

[0037]Step 3. Mix 10 parts of coke with 50 parts of synthetic sanda...

Embodiment 3

[0039] Step 1. Select 100 parts of silicon particles with a D50 particle size of 500nm and 2 parts of siloxane coupling agent γ-(methacryloyloxy)propyltrimethoxysilane KH570, and after mechanical mixing, ultrasonically disperse in anhydrous In ethanol, supersonicate at 50°C for 0.5 hours to carry out surface grafting treatment, filter and dry for later use;

[0040] Step 2. Add 5 parts of dimethyldiethoxysilane, 10 parts of cyclohexyltrimethoxy, and 3 parts of ethyl orthosilicate to 100 parts of aqueous solution at 30°C for 0.5 hours to hydrolyze 15 parts of the product of step 1 Add as a nucleating substance to disperse evenly, raise the temperature to 50°C, and carry out copolymerization coating of silicone emulsion under a weak alkalinity with a pH value of 8. The reaction time is 4 hours, and filter and dry to obtain microspheres with a D50 of 4 microns substance;

[0041] Step 3. Dissolve 10 parts of coal tar pitch in 40 parts of N-methylpyrrolidone, then add 20 parts of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com