Single-sided hot-melt termination adhesive tape for lithium battery and preparation method of single-sided hot-melt termination adhesive tape

A technology for terminating tapes and lithium batteries, applied in the direction of adhesives, adhesive types, film/sheet adhesives, etc. The effect of excellent electrolyte aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

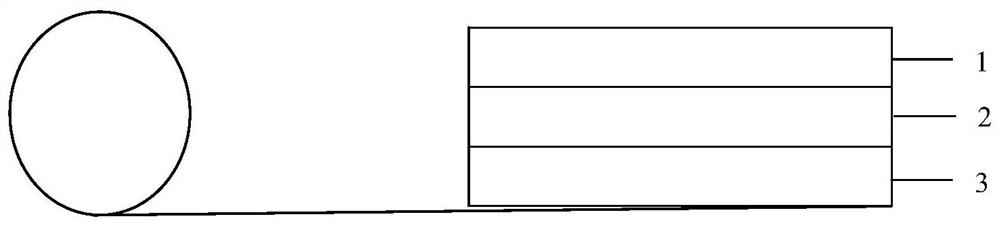

[0030] A single-sided hot-melt terminated adhesive tape for lithium batteries, with a total thickness of 25um, including a first pressure-sensitive adhesive layer, a second adhesive layer, and a third substrate layer arranged in sequence from top to bottom;

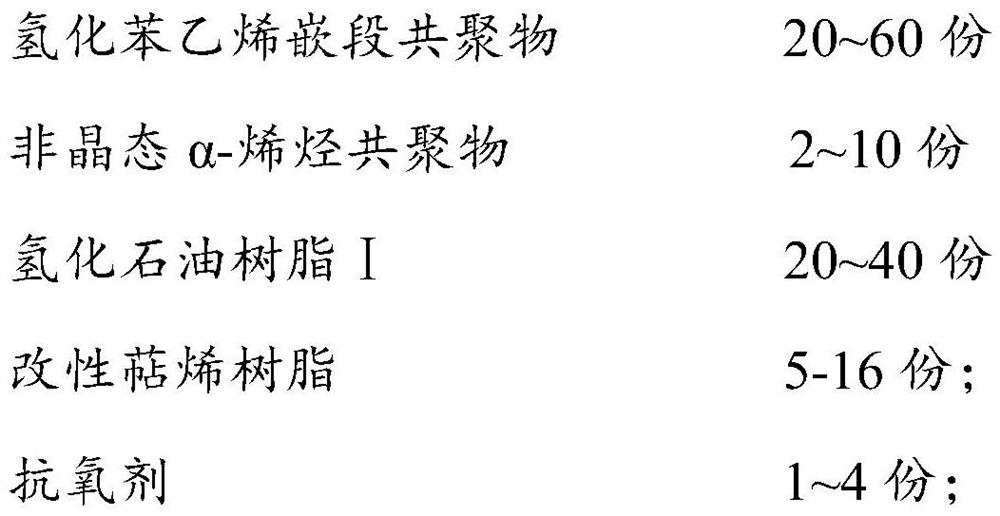

[0031] The coating thickness of the first pressure-sensitive adhesive layer is 10 μm, and includes the following components in parts by weight:

[0032] Hydrogenated styrene block copolymer SEBS G1654 (Kraton) 45 parts, amorphous α-olefin copolymer Vestoplast 408 (Evonik) 5 parts, hydrogenated petroleum resin ARKON P90 (Arakawa) 40 parts, modified terpene resin 5 parts, Antioxidant Irganox 1010 1 part;

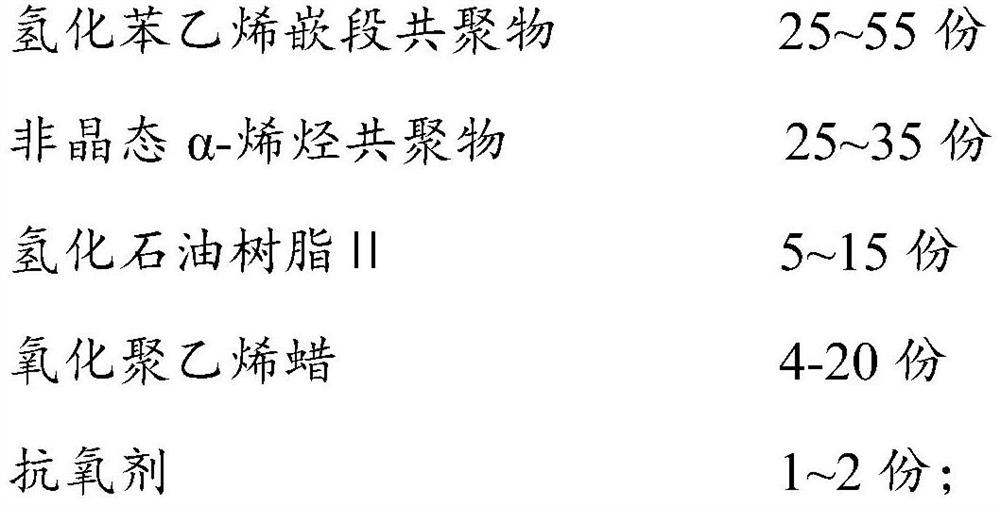

[0033] The coating thickness of the second adhesive layer is 5 μm, and includes the following components in parts by weight:

[0034] Hydrogenated styrene block copolymer SEBS G1654 (Kraton) 40 parts, amorphous α-olefin copolymer Vestoplast 408 (Evonik) 35 parts, hydrogenated petroleum resin ARKON P125 (Arakawa) 15 parts...

Embodiment 2

[0037] A single-sided hot-melt terminated tape for lithium batteries, with a total thickness of 20um, including a first pressure-sensitive adhesive layer, a second adhesive layer, and a third substrate layer arranged in sequence from top to bottom;

[0038] The coating thickness of the first pressure-sensitive adhesive layer is 5 μm, and includes the following components in parts by weight:

[0039] Hydrogenated styrene block copolymer SEBS G1650 (Kraton) 47 parts, amorphous α-olefin copolymer Vestoplast 308 (Evonik) 5 parts, hydrogenated petroleum resin ARKON P100 (Arakawa) 40 parts, modified terpene resin 5 parts, Antioxidant Irganox 1010 1 part;

[0040] The coating thickness of the second adhesive layer is 5 μm, and includes the following components in parts by weight:

[0041] Hydrogenated styrene block copolymer SEBS G1650 (Kraton) 42 parts, amorphous α-olefin copolymer Vestoplast 308 (Evonik) 35 parts, hydrogenated petroleum resin ARKON P125 (Arakawa) 15 parts, oxidize...

Embodiment 3

[0044] A single-sided hot-melt terminated tape for lithium batteries, with a total thickness of 16um, including a first pressure-sensitive adhesive layer, a second adhesive layer, and a third substrate layer arranged in sequence from top to bottom;

[0045] The coating thickness of the first pressure-sensitive adhesive layer is 3 μm, and includes the following components in parts by weight:

[0046] Hydrogenated styrene block copolymer SEPS G1657 (Kraton) 45 parts, amorphous α-olefin copolymer Vestoplast 508 (Evonik) 10 parts, hydrogenated petroleum resin ARKON P115 (Arakawa) 39 parts, modified terpene resin 5 parts, Antioxidant Irganox 1076 1 part;

[0047] The coating thickness of the second adhesive layer is 3 μm, and includes the following components in parts by weight:

[0048] Hydrogenated styrene block copolymer SEPS G1657 (Kraton) 42 parts, amorphous α-olefin copolymer Vestoplast 508 (Evonik) 35 parts, hydrogenated petroleum resin ARKON P140 (Arakawa) 15 parts, oxidized...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com