Metal-doped vanadium-based oxide nano material as well as preparation method and application thereof

A nano-material and metal doping technology, applied in vanadium oxide, electrochemical generators, structural parts, etc., can solve the problem of low rate performance battery life, achieve good rate performance, shorten ion diffusion path, and enhance kinetics Effects on performance and cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Example 1: Mg 0.02 V 5 o 12 Preparation of Cathode Active Material for Aqueous Zinc-ion Batteries

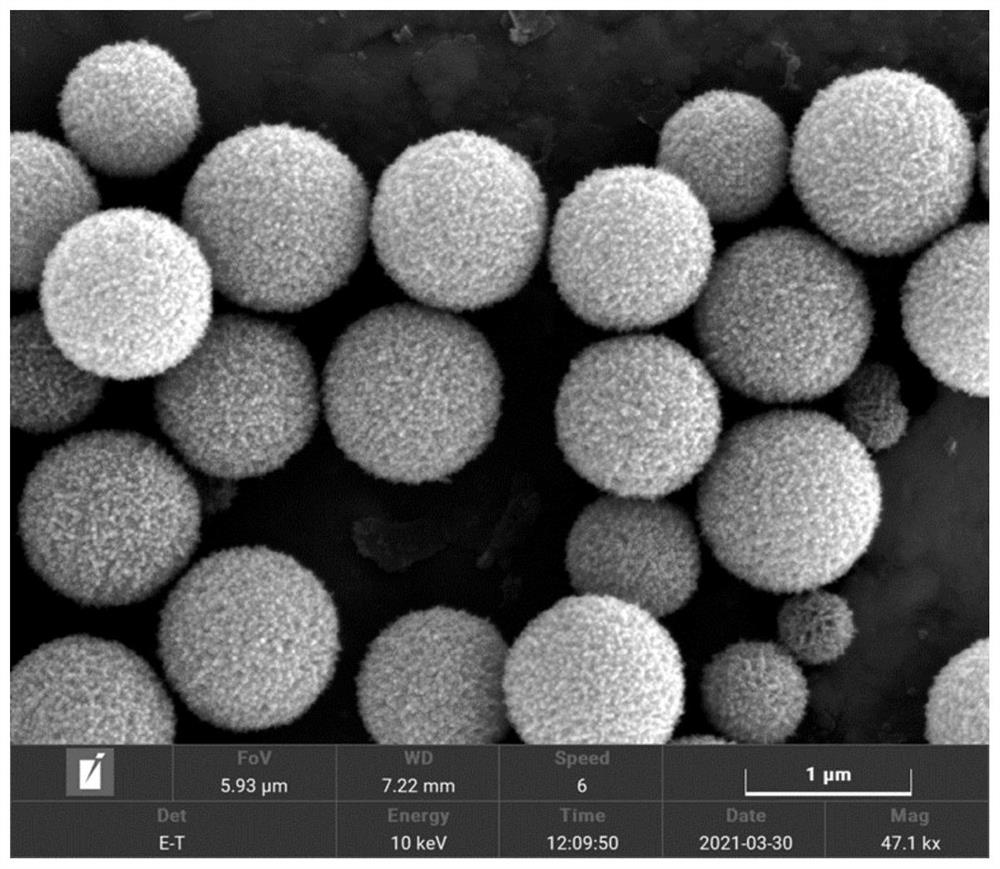

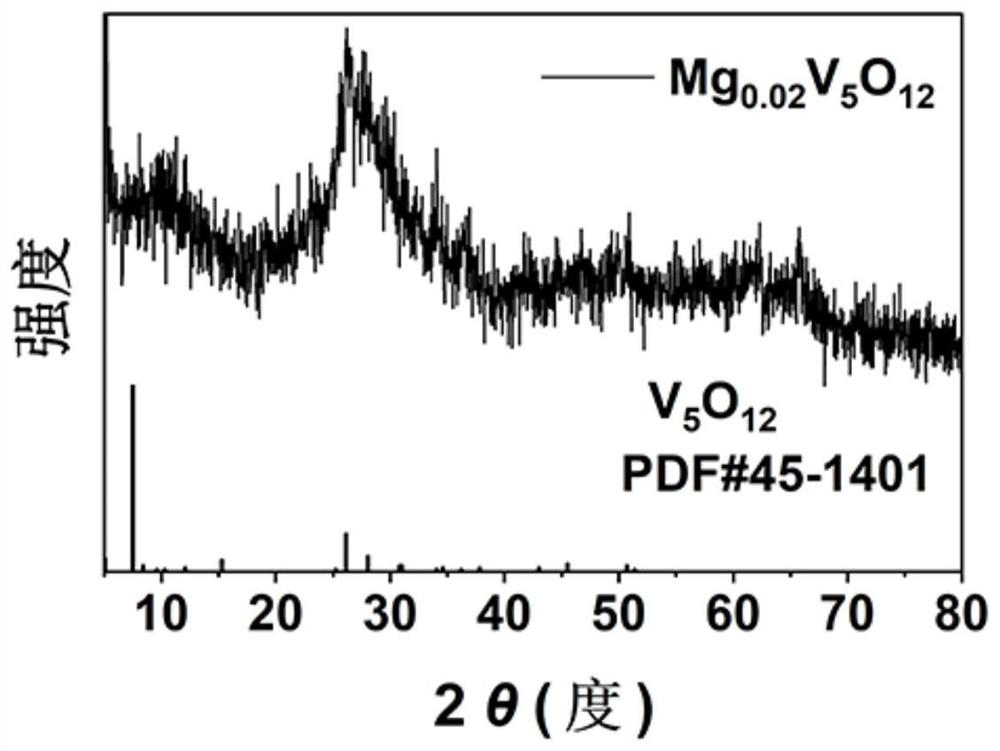

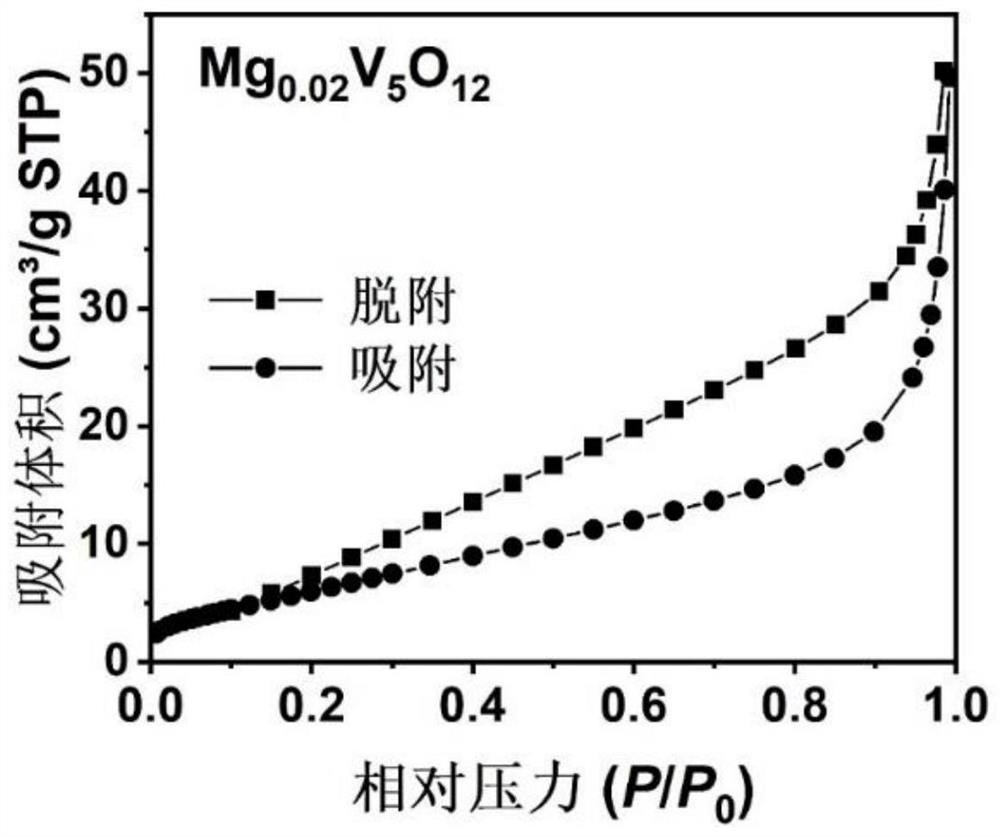

[0052] Will be commercial V 2 o 5 and oxalic acid were dissolved in deionized water at a molar ratio of 1:3 to obtain a precursor solution A with a concentration of 0.33 mol / L. Then magnesium acetate (Mg:V molar ratio of 1:50) was added to precursor solution A to obtain precursor solution B containing magnesium ions. Take 1.2 mL of precursor solution B and add it into a high-pressure digestion tank filled with 20 mL of isopropanol, and react at 200 °C for 2 h. The obtained product was placed in a tube furnace, and annealed at 1 °C / min to 250 °C for 2 h in an air atmosphere to obtain Mg 0.02 V 5 o 12 Porous nanosphere structure, whose FESEM as figure 1 As shown, XRD as figure 2 shown. Its nitrogen adsorption-desorption curve is as follows image 3 As shown, the BET specific surface area is 39.83m 2 / g.

Embodiment 2

[0053] Example 2: Mg 0.01 V 5 o 12 Preparation of Cathode Active Material for Aqueous Zinc-ion Batteries

[0054] Will be commercial V 2 o 5 and oxalic acid were dissolved in deionized water at a molar ratio of 1:3 to obtain a precursor solution A with a concentration of 0.33 mol / L. Then magnesium acetate was added to the precursor solution A (the molar ratio of Mg:V was 1:100) to obtain the precursor solution B containing magnesium ions. Take 2.4 mL of precursor solution B and add it into a high-pressure digestion tank filled with 50 mL of isopropanol solvent, and react at 200 °C for 2 h. The obtained product was placed in a tube furnace, and annealed at 1 °C / min to 250 °C for 2 h in an air atmosphere to obtain Mg 0.01 V 5 o 12 Porous nanosphere structure.

Embodiment 3

[0055] Example 3: Co 0.006 V 5 o 12 Preparation of Cathode Active Material for Aqueous Zinc-ion Batteries

[0056] Will be commercial V 2 o 5 and oxalic acid were dissolved in deionized water at a molar ratio of 1:2 to obtain a precursor solution A with a concentration of 0.5 mol / L. Then cobalt acetate (the molar ratio of Co:V is 1:150) was added to precursor solution A to obtain precursor solution B containing cobalt ions. Take 1.2 mL of precursor solution B and add it into a high-pressure digestion tank filled with 20 mL of isopropanol solvent, and react at 200 °C for 2.5 h. The obtained product was placed in a tube furnace, and annealed at 1 °C / min to 250 °C for 2 h in an air atmosphere to obtain Co 0.006 V 5 o 12 Porous nanosphere structure, whose FESEM as Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com