Hydrophobic and oleophobic coating as well as preparation method and product thereof

A hydrophobic and oleophobic coating technology, which is applied in textiles and papermaking, fiber types, ultrasonic/sonic fiber treatment, etc., can solve problems such as limiting the use of initiators, and achieve the effect of improving oleophobic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Place a strip material made of 70% nylon 66 in the reaction chamber of the plasma chamber, and continuously evacuate the reaction chamber to make the vacuum degree reach 80 millitorr; feed helium gas with a flow rate of 50 sccm, and start the plasma discharge to the substrate Pretreatment is carried out. The pretreatment stage is pulse discharge. The discharge power supply is a pulse bias power supply in constant power mode. The power is 400W, the pulse frequency is 50KHz, the duty cycle is 10%, and the discharge time is 5 seconds.

[0049] Then, hexamethylcyclohexasiloxane is vaporized and introduced into the reaction chamber, the pressure is constant at 80 mTorr, the monomer flow rate is 300ul / min, the coating stage is pulse discharge, the power is 400W, the pulse frequency is 50KHz, and the duty cycle The ratio is 10%, the temperature inside the chamber is 55°C, the vaporization temperature of the monomer is 110°C, and the coating process time is 320 seconds.

[0050...

Embodiment 2

[0056] Put the clothing cloth made of polyester fiber into the reaction chamber of the plasma chamber, and perform coating according to the method described in the above-mentioned embodiment 1. After the coating is finished, the clothes cloth made of polyester fiber is tested, and the polyester fiber material is measured. The static hydrophobic angle of the clothing fabric is 150 degrees.

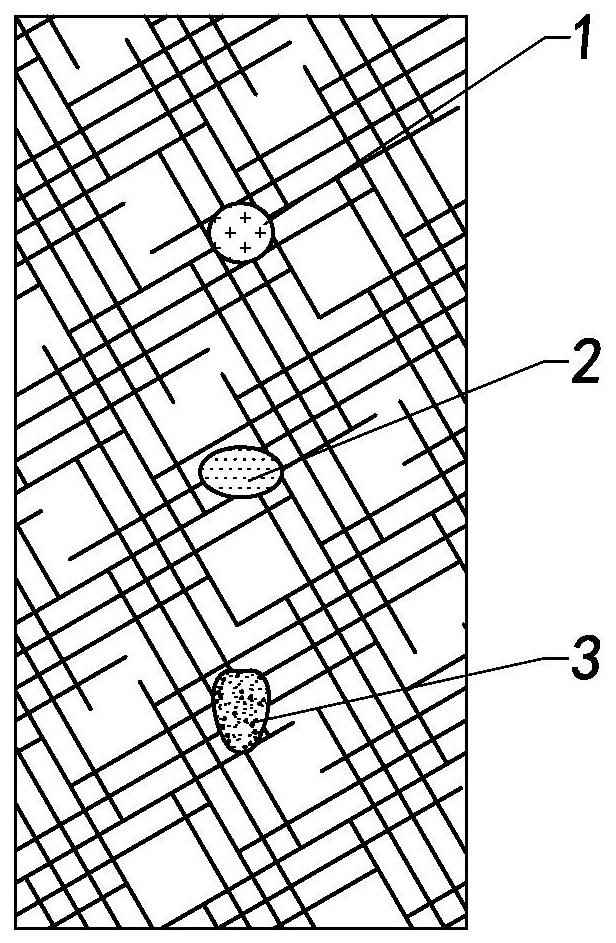

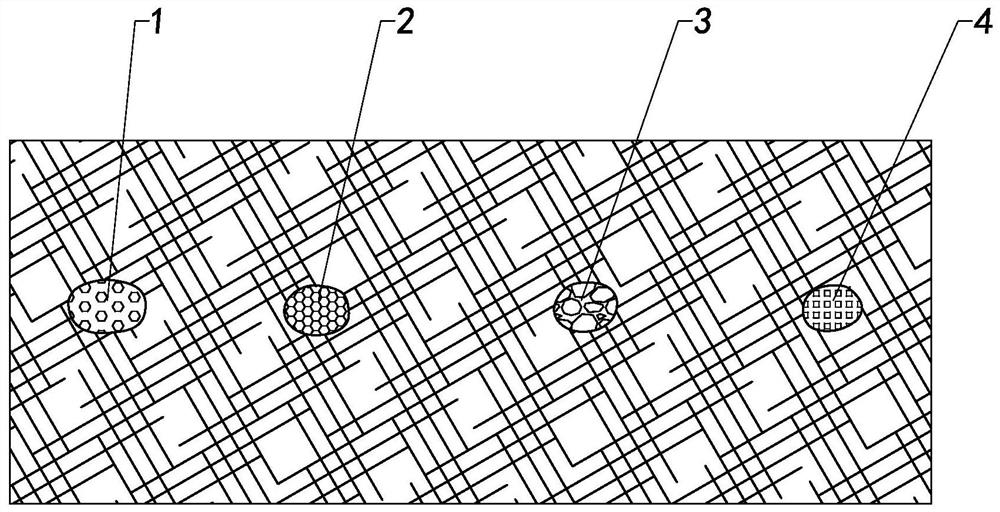

[0057] The oleophobic angle of the polyester fiber clothing fabric measured with olive oil is 120 degrees, the oleophobic angle measured with salad oil is 123 degrees, and the oleophobic angle measured with sunflower oil is 123 degrees. can refer to attached image 3 , image 3 1-water, 2-olive oil, 3-salad oil, 4-sunflower oil.

[0058] Test the waterproof and oil-proof grade according to the above-mentioned test method, the waterproof grade is 5, and the oil-proof grade is 4.

Embodiment 3

[0060] Put the cloth made of cotton into the reaction chamber of the plasma chamber, and perform coating according to the method described in the above-mentioned embodiment 1. After the coating is finished, the cloth made of cotton is tested, and the static hydrophobic angle of the cloth made of cotton is measured as 140 degrees, waterproof level is 5. The static oleophobic angle measured with n-hexadecane is 111 degrees, the oleophobic angle measured with n-tetradecane is 100 degrees, the oleophobic angle measured with n-dodecane is 83 degrees, and the oil resistance level is level 4.

[0061] The comparative example of embodiment 1

[0062] Scheme (1) only deposits the first layer of the coating, the raw material is hexamethylcyclohexasiloxane, and the strip-shaped material made of 70% nylon 66 is placed in the reaction chamber of the plasma chamber, and the reaction chamber is continuously pumped Vacuum to make the vacuum degree reach 80 millitorr; pass helium gas, the fl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap