High-weather-resistance anti-sticking coating and preparation method thereof

An anti-sticking and coating technology, applied in anti-fouling/underwater coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of expensive fluorine-containing resins, slow drying speed, and high cost of use, and achieve improved wiping performance , strong adhesion, excellent wear-resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

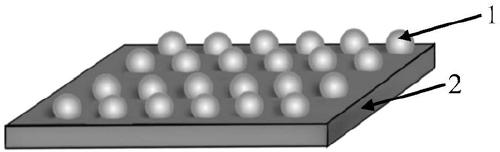

Image

Examples

Embodiment 1~3

[0045] The preparation method of high weather resistance anti-sticking coating comprises the following steps:

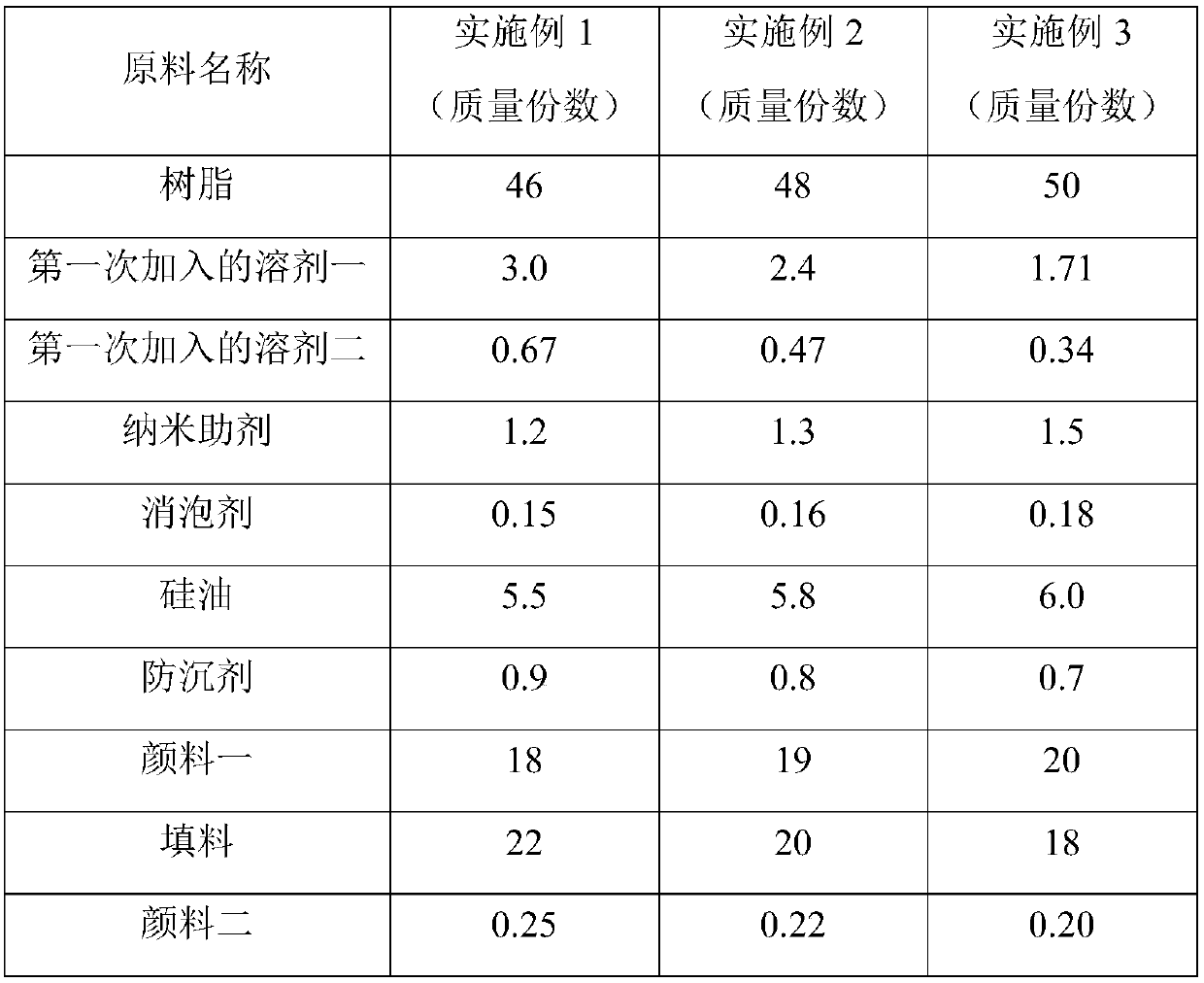

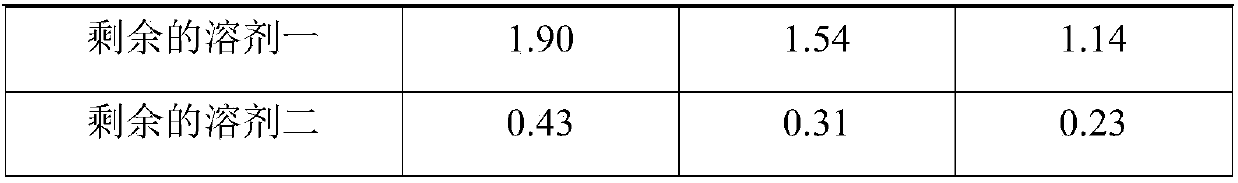

[0046] Step 1, prepare the main agent: mix the resin, solvent 1 and solvent 2 added for the first time, stir evenly, then add defoamer and nano additives, disperse for 5 minutes, then slowly add anti-sedimentation agent and silicone oil, After dispersing for 3 minutes, add pigment 1, filler and pigment 2 in order, disperse at 850r / min for 10min, then increase the speed and disperse at 3000r / min for 20min, then reduce the speed to 1600r / min, then add the remaining Solvent 1 and the remaining solvent 2 can be continuously dispersed for 3 minutes; the mass parts of each component in Step 1 of Examples 1-3 are shown in Table 1.

[0047] Table 1

[0048]

[0049]

[0050] Step 2: mix the main agent and the curing agent uniformly to prepare the paint, and see Table 2 for the mass parts ratio of the main agent and the curing agent in Step 2 of Examples 1-3.

[0051]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com