Barrier film for food paper and paperboard, food paper and paperboard

A technology for food paper and barrier film, which is applied to the barrier film for paperboard and the fields of food paper, food paper and cardboard, can solve the problems of insufficient barrier performance, easy adhesion, etc., and achieves good continuity and airtightness, good ethanol resistance, Effects of low solubility parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

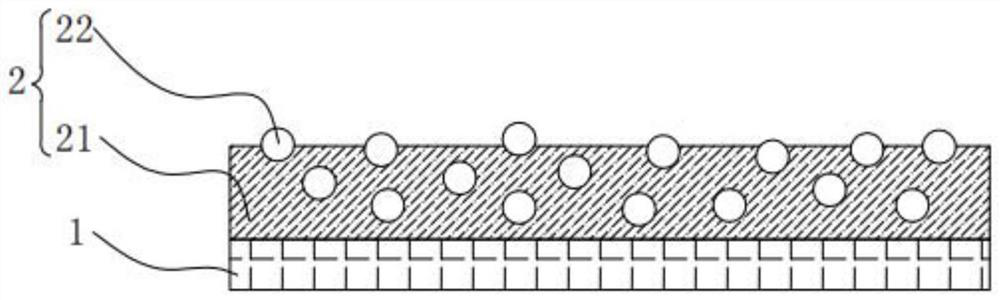

Image

Examples

preparation example Construction

[0040] In some embodiments, the preparation method of the component A comprises the following steps:

[0041] ① Add water and emulsifier to the reaction bottle. ②Heating to raise the temperature, adding the pre-emulsified monomer mixture with a calculated Tg of -20-10°C and an initiator to initiate polymerization. ③Add neutralizer to adjust pH value, and obtain emulsion with particle size range of 0.02-0.2 microns through selection and matching of emulsifiers and adjustment of hydrophilic-lipophilic balance of monomers.

[0042] In some embodiments, the preparation method of the component B comprises the following steps:

[0043] ① Add water and emulsifier to the reaction bottle. ②Heating to raise the temperature, adding the pre-emulsified monomer mixture with a calculated Tg of 10-120°C and an initiator to initiate polymerization. The addition method of its monomer and initiator can be the same as the preparation process of component A, or a different addition method can b...

Embodiment 1

[0069] This embodiment is used to illustrate the barrier coating for food paper disclosed by the present invention, food paper and its preparation method, including the following steps:

[0070]Step 1: Prepare acrylate copolymer emulsion component A and acrylate copolymer emulsion component B by means of emulsion polymerization, and obtain acrylate emulsion component C by dispersion polymerization in an alcohol-water mixed solvent, wherein it has been determined that in component A: The solid content is 38.8%, the average particle size of the polyacrylate is 65nm, and the Tg value is -7°C. In component B: the solid content is 40.1%, the average particle diameter of polyacrylate is 71nm, and the Tg value is 50°C. In component C: the solid content is 20.7%, the average particle size of polyacrylate is 3.6 μm, and the Tg value is 103°C.

[0071] Step 2: Mix component A, component B and component C with a mass ratio of 46:46:8, add wetting agent, thickener, defoamer and pH regula...

Embodiment 2

[0074] This embodiment is used to illustrate the barrier coating for food paper disclosed by the present invention, food paper and its preparation method, including the following steps:

[0075] Step 1: Prepare acrylate copolymer emulsion component A and acrylate copolymer emulsion component B by means of emulsion polymerization, and obtain acrylate emulsion component C by dispersion polymerization in an alcohol-water mixed solvent, wherein it has been determined that in component A: The solid content is 45.2%, the average particle diameter of the polyacrylate is 76nm, and the Tg value is -16°C. In component B: the solid content is 46.1%, the average particle diameter of polyacrylate is 52nm, and the Tg value is 58°C. In component C: the solid content is 25.3%, the average particle diameter of polyacrylate is 4.7 μm, and the Tg value is 95°C.

[0076] Step 2: Mix component A, component B and component C with a mass ratio of 65:35:7, add wetting agent, thickener, defoamer and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com