High dye-carrying adhesive for disperse dye wash-free printing and preparation method

A disperse dye, no-wash technology, applied to the application of printing adhesives in polyester disperse dye no-wash printing, and the preparation of silicone-modified acrylate adhesives, which can solve the problem of difficult to ensure silicone-modified monomers Problems such as copolymerization, large difference in latex particle size, emulsion breaking stability, etc., to achieve the effect of improving hand feeling, low equipment requirements, and improving rubbing color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) 1.16g sodium dodecyl sulfate (SDS), 0.77g propyleneoxypropyl alkylphenol-based polyether ammonium sulfate (V-20S) and 0.77g fatty alcohol polyoxyethylene ether (O-10) Dissolve in 70 g of deionized water, heat up (60° C.) and stir (800 r / min) for 15 minutes, mix well, and cool the solution to room temperature to obtain a pre-emulsion.

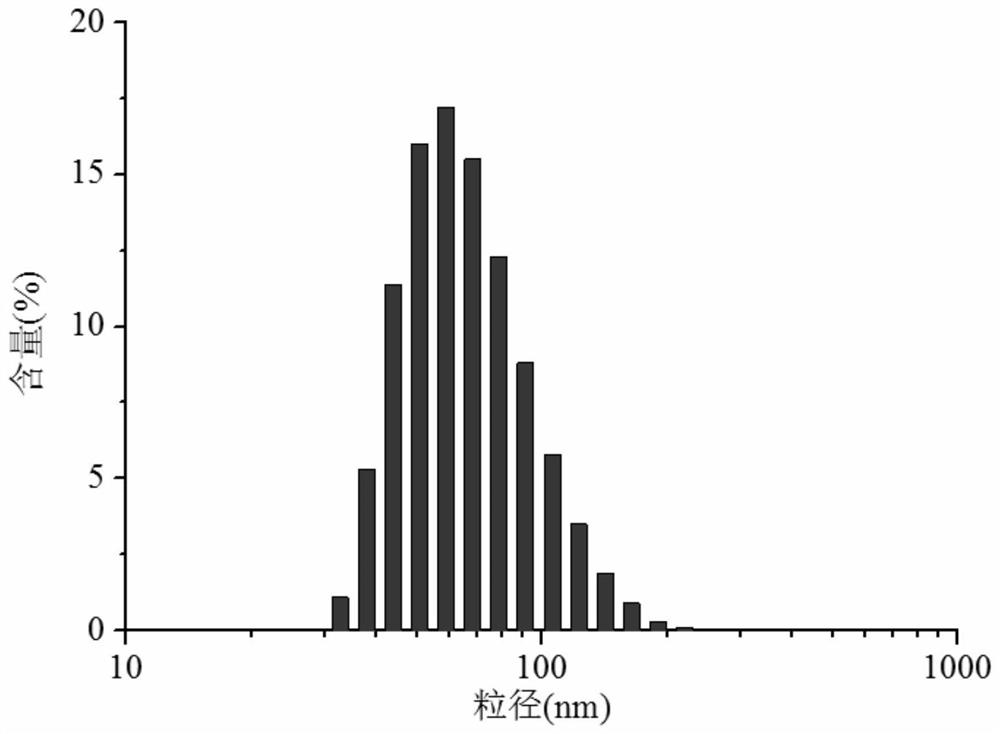

[0027] (2) 22g isooctyl acrylate, 18g methyl methacrylate and 1.6g double-ended vinyl polysiloxane (the structure is shown in the figure below, the average degree of polymerization n is 24), 0.6g acrylic acid, n-hexadecane 1.5g was mixed evenly, added to the above-mentioned pre-emulsion, stirred at a high speed of 1200r / min for 15 minutes, and then ultrasonically pulverized in an ice-water bath for 20 minutes to obtain a fine emulsion.

[0028]

[0029] (3) take by weighing above-mentioned 1 / 3 of the mini-emulsion and pour it into the reaction vessel, add 3.3g initiator solution (0.3g ammonium persulfate is dissolved in 10g water),...

Embodiment 2

[0043] (1) 1.16g sodium dodecyl sulfate (SDS), 0.77g propyleneoxypropyl alkylphenol-based polyether ammonium sulfate (V-20S) and 0.77g fatty alcohol polyoxyethylene ether (O-10) Dissolve in 70 g of deionized water, heat up (60° C.) and stir (800 r / min) for 15 minutes, mix well, and cool the solution to room temperature to obtain a pre-emulsion.

[0044] (2) 19g isooctyl acrylate, 21g methyl methacrylate and 1.6g double-ended vinyl polysiloxane (the structure is shown in the figure below, the average degree of polymerization n is 24), 0.6g acrylic acid, n-hexadecane 1.5g was mixed evenly, added to the above-mentioned pre-emulsion, stirred at a high speed of 1200r / min for 15 minutes, and then ultrasonically pulverized in an ice-water bath for 20 minutes to obtain a fine emulsion.

[0045]

[0046] (3) take by weighing above-mentioned 1 / 3 of the mini-emulsion and pour it into the reaction vessel, add 3.3g initiator solution (0.3g ammonium persulfate is dissolved in 10g water),...

Embodiment 3

[0055] (1) Dissolve 2.7g of sodium dodecyl sulfate (SDS) in 70g of deionized water, heat up (60°C) and stir (800r / min) for 15 minutes, mix well, and cool the solution to room temperature to obtain a pre-emulsion.

[0056] (2) 22g isooctyl acrylate, 18g methyl methacrylate and 1.6g double-terminated vinyl polysiloxane (the structure is shown in the figure below, the average degree of polymerization n is 24), 0.6g acrylic acid, 1.5g normal ten Hexane was mixed evenly, added to the above-mentioned pre-emulsion, stirred at a high speed of 1200 r / min for 15 minutes, and then ultrasonically pulverized in an ice-water bath for 20 minutes to obtain a fine emulsion.

[0057]

[0058] (3) take by weighing above-mentioned 1 / 3 of the mini-emulsion and pour it into the reaction vessel, add 3.3g initiator solution (0.3g ammonium persulfate is dissolved in 10g water), stir and be warmed up to 78 ℃, treat the emulsion as blue light and warm up to 82 ℃, The remaining 2 / 3 of the mini-emulsio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com