Pressure-sensitive adhesive composition and adhesive article comprising the pressure-sensitive adhesive composition

A pressure-sensitive adhesive, composition technology, applied in the direction of polymer adhesive additives, film/sheet adhesives, adhesive types, etc., can solve uncommon problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0132] All parts, percentages, ratios, etc. in the examples, as well as in the remainder of this specification, are by weight unless otherwise indicated.

[0133] Materials used in the examples

[0134]

[0135]

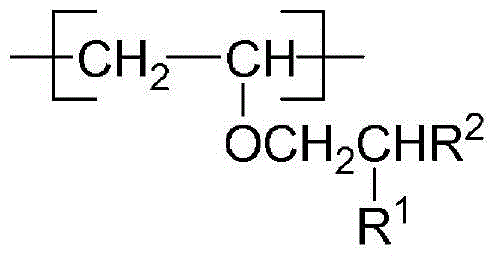

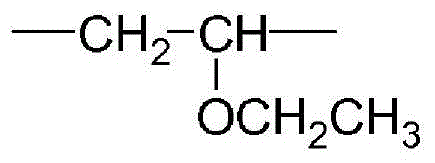

[0136] Preparation of vinyl ethers used in the examples

[0137] The mixtures of PdTFA, DPP, BVE, the indicated alcohols, and TEA heated to 75°C over time under nitrogen are shown in Table 1. Cool and filter the reaction mixture through a short plug of silica in a sintered glass funnel. The silica was washed with 20 mL of hexane each time. The filtrate was concentrated under vacuum to afford a yellow crude product. The crude product was mixed with equal parts of hexane and purified by column chromatography on silica gel using hexane as solvent. The collected fractions were concentrated under vacuum to afford the final product as a colorless oil (Preparations 1-5) or white solid (Preparations 6-7). Details are recorded in Table 1 (below).

[0138]

...

example 1 to 7 and comparative example A to C

[0154] Polymers were prepared and tested as follows. From silicone rubber sheet (1.59 mm thick, part no. DSP6038GP-062, Diversified Silicone Products, Santa Fe Springs, California) Cut a rectangular mold with internal dimensions of 25.4mm x 12.7mm. The silicone mold was placed between two microscope slides and the slides were held together by clamps. A mixture of the desired vinyl ether monomer, butanediol divinyl ether (BDDVE) and 1% by weight boron trifluoride diethyl ether (BTFE solution) in the amounts reported in Table 3 was mixed in a vial and then injected into the mold middle. The clamped assemblies were left standing on edge and left at room temperature for 24 hours. The assembly was then cooled with dry ice for five minutes, and one slide was carefully removed to leave solidified polymer on the surface of one slide.

[0155] table 3

[0156] example vinyl ether monomer Vinyl ether monomer, g BDDVE crosslinker, g BTFE solution, g Comparat...

example 8-14 and comparative example 4-6

[0160] Pressure sensitive adhesive (PSA) copolymer slabs were prepared and tested according to the same method used for Examples 1-7. Table 5 (below) records the amounts of components used to prepare each example.

[0161] table 5

[0162]

[0163] Adhesion of the samples was determined using the Probe Adhesion Test according to Test Method 3. The results are reported in Table 6 (below).

[0164]

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com