Silicon carbide diode and preparation method thereof

A silicon carbide diode, silicon carbide technology, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as instability, and achieve the effects of improving uniformity, improving device performance, and high flat top uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

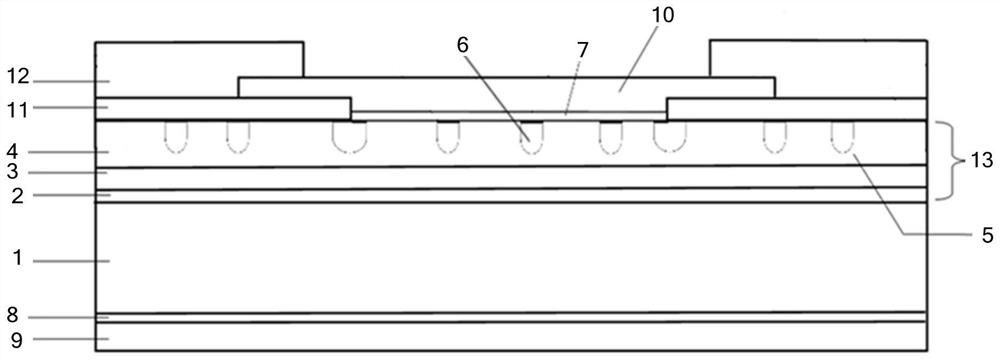

[0057] Such as figure 1 As shown, this embodiment provides a silicon carbide diode, including a silicon carbide substrate 1, a multi-layer epitaxial layer, a plurality of P-type voltage divider rings 5, a plurality of P-type diffusion regions 6, a Schottky barrier layer 7, Ohmic contact layer 8 , back metal electrode 9 , front metal electrode 10 , silicon dioxide film 11 and polyimide layer 12 . Both the back metal electrode 9 and the silicon carbide substrate 1 are arranged on the ohmic contact layer 8, the ohmic contact layer 8 is located between the back metal electrode 9 and the silicon carbide substrate 1, and the multilayer epitaxial layer 13 is arranged on the silicon carbide substrate 1 , the silicon carbide substrate 1 is located between the multilayer epitaxial layer 13 and the ohmic contact layer 8, and both ends of the multilayer epitaxial layer 13 are provided with a silicon dioxide film 11, and the multilayer epitaxial layer 13 is located between the silicon diox...

Embodiment 2

[0071] Those skilled in the art can understand this embodiment as a more specific description of Embodiment 1.

[0072] Such as figure 1 As shown, this embodiment provides a silicon carbide diode prepared by laser activation and laser ohmic contact and its preparation method, a silicon carbide diode, a silicon carbide substrate 1, a silicon carbide isolation buffer layer 2, a multi-layer epitaxial layer, a multi-layer A P-type voltage divider ring 5, a plurality of P-type diffusion regions 6, a Schottky barrier layer 7, an ohmic contact layer 8, a back metal electrode 9, a front metal electrode 10, a silicon dioxide film 11 and a polyimide layer 12.

[0073] The silicon carbide isolation buffer layer 2 is grown on the silicon carbide substrate 1, and the first epitaxial layer 3 and the second epitaxial layer 4 are grown on the silicon carbide isolation buffer layer 2 (the silicon carbide isolation buffer layer 2, the first epitaxial layer 3, The second epitaxial layer 4 form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com