Process technology and device for simultaneously recovering various gases such as hydrogen and methane gas from petrochemical exhaust gas emissions

A process technology, tail gas technology, applied in membrane technology, gas treatment, chemical instruments and methods, etc., can solve the problem of undisclosed hydrogen-pressure swing adsorption, etc., and achieve the effect of saving energy consumption and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

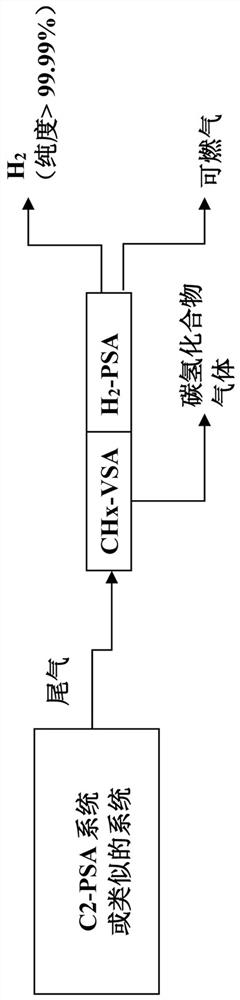

[0099] Separating and recovering hydrogen and hydrocarbon gases from the tail gas of Sinopec C2-PSA unit, and producing gas with higher calorific value.

[0100] The exhaust gas composition of the C2-PSA unit is as follows (in actual operation, the exhaust gas composition often has a fluctuation range of 10%):

[0101]Table 1 Components of exhaust gas from C2-PSA plant

[0102]

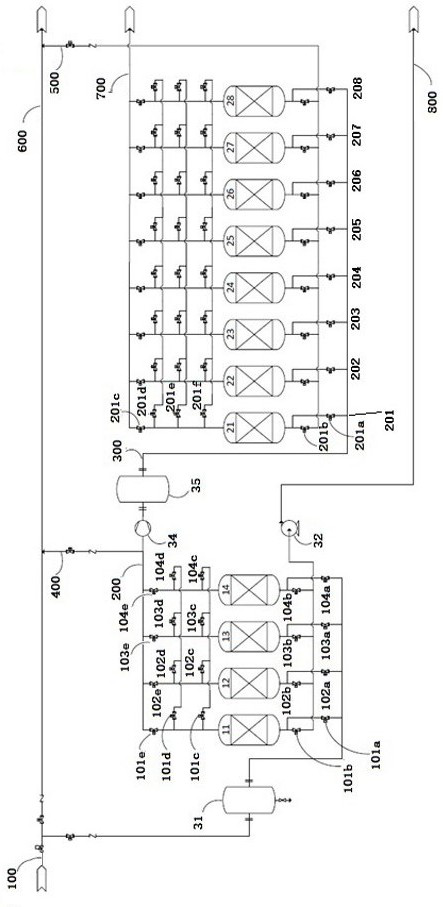

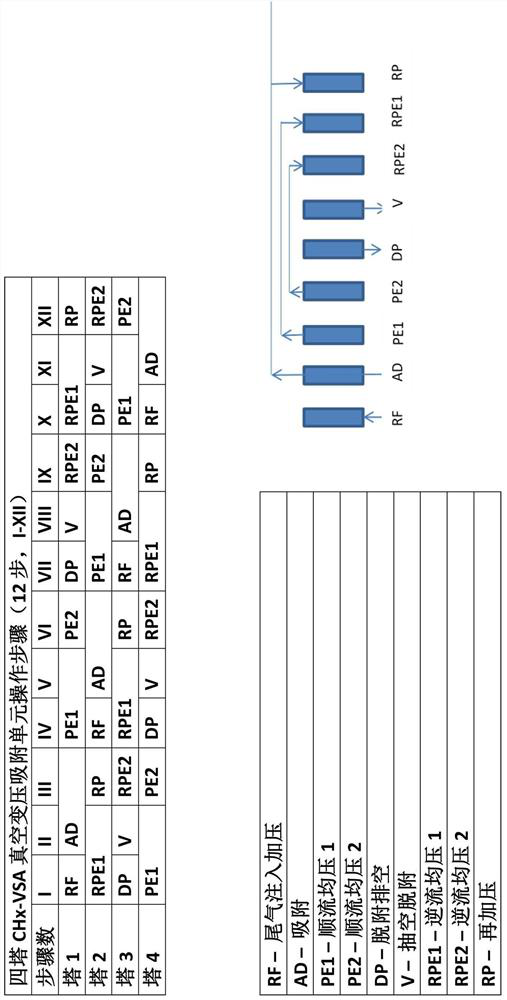

[0103] According to the parameters listed in Table 3 and Table 4 use such as figure 1 Shown gas separation and recovery process technology of the present invention, use such as figure 2 The device shown, such as image 3 The shown CHx-VSA adsorption tower operating steps and process cycle design and Figure 4 Shown H 2 - PSA adsorption tower operation steps and process cycle design to separate the above-mentioned tail gas. Wherein, the number of adsorption towers in the CHx-VSA device is 4, and the diameter of the adsorption towers in each CHx-VSA device is 30 centimeters, and the working len...

Embodiment 2

[0106] Separation and recovery of hydrogen and hydrocarbon gases from the tail gas of Sinopec's similar C2-PSA plant system, and produce gas with higher calorific value.

[0107] The exhaust gas composition in this example is as follows (in actual operation, the exhaust gas composition often has a fluctuation range of 10%):

[0108] Table 2 Exhaust gas components emitted by similar C2-PSA devices

[0109]

[0110] According to the parameters listed in Table 3 and Table 4 use such as figure 1 Shown gas separation and recovery process technology of the present invention, such as figure 2 The device shown, such as image 3 The shown CHx-VSA adsorption tower operating steps and process cycle design and Figure 4 Shown H 2 - PSA adsorption tower operation steps and process cycle design to separate the above-mentioned tail gas. Wherein, the number of adsorption towers in the CHx-VSA device is 4, and the diameter of the adsorption towers in each CHx-VSA device is 300 centime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com