Preparation method of milk protein loaded astaxanthin emulsion combined with polyphenol and glycosylation modification

A milk protein and astaxanthin technology, applied in the field of food processing, can solve the problems of low cost, poor stability of astaxanthin, low bioavailability, etc., to improve poor stability, improve antioxidant performance, and reduce the risk of hyperglycemia. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The preparation method of whey protein isolate combined with caffeic acid and glycosylation modification provided in this example comprises the following steps:

[0042] (1) Preparation of whey protein isolate-caffeic acid covalent substance:

[0043] Dissolve 1 g whey protein isolate in 100 mL PBS (10 mM, pH=7.4), add 0.25 g ascorbic acid and 1 mL H 2 o 2 (5mol / L), fully oscillate and let stand at room temperature for 2 hours, add 0.2g caffeic acid, mix well and continue to stand for 24 hours, then dialyze the solution for 48 hours and vacuum freeze-dry it to obtain whey protein isolate-coffee Acid Covalent Powder.

[0044] (2) Glycosylation modification of whey protein isolate-caffeic acid covalent substance:

[0045]Dissolve whey protein isolate-caffeic acid covalent powder and glucose in water at a mass ratio of 1:1, adjust the pH to 7.4, and mix thoroughly; freeze-dry the mixed solution, and freeze-dry the powder at a temperature of 60°C and humidity Maillard r...

Embodiment 2

[0048] The preparation method of combined caffeic acid and glycosylated modified casein provided in this example, the specific scheme is as follows:

[0049] (1) Preparation of casein-caffeic acid covalent substance:

[0050] Dissolve 1 g of casein in 100 mL of PBS (10 mM, pH=7.4), add 0.25 g of ascorbic acid and 1 mL of H 2 o 2 (5mol / L), fully shaken and left at room temperature for 2h, add 0.2g of caffeic acid, mix well and continue to stand for 24h, then dialyze the solution for 48h and vacuum freeze-dry it.

[0051] (2) Glycosylation modification of casein-caffeic acid covalent species

[0052] Dissolve casein-caffeic acid covalent powder and glucose in water at a mass ratio of 1:1, adjust the pH to 7.4, and mix thoroughly; freeze-dry the mixed solution, and freeze-dry the powder at a temperature of 60°C and a humidity of 79%. Maillard reaction (24h) was carried out under the condition to obtain casein-caffeic acid-glucose covalent complex.

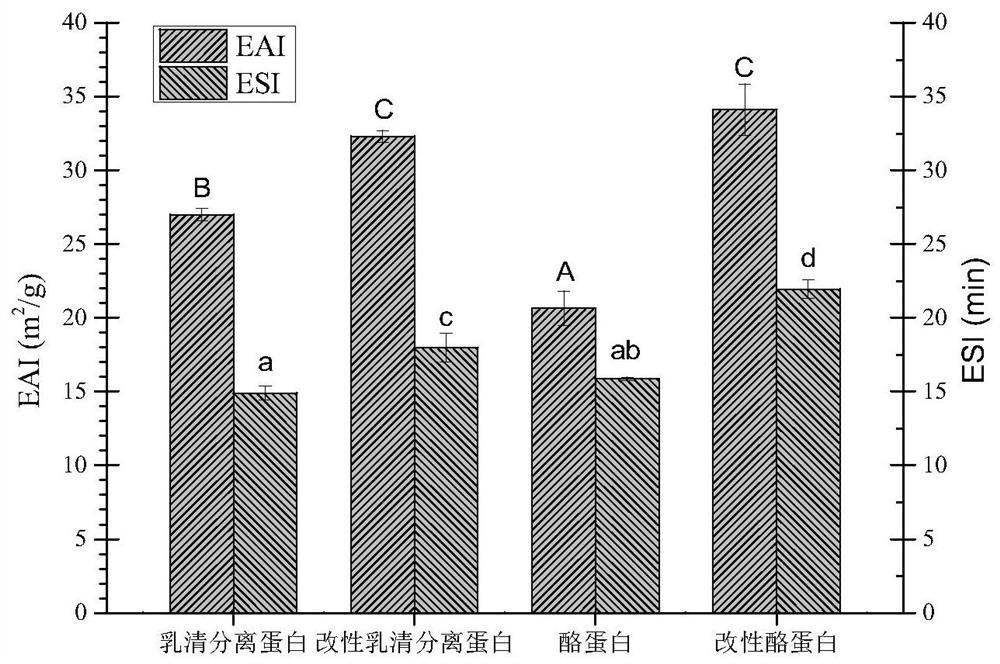

[0053] The control group o...

Embodiment 3

[0055] The method for preparing the astaxanthin-loaded emulsion of combined caffeic acid and glycosylated modified casein provided in this example is as follows:

[0056] (1) Preparation of casein-caffeic acid covalent substance:

[0057] Dissolve 1 g of casein in 100 mL of PBS (10 mM, pH=7.4), add 0.25 g of ascorbic acid and 1 mL of H 2 o 2 (5mol / L), fully shaken and left at room temperature for 2h, add 0.2g of caffeic acid, mix well and continue to stand for 24h, then dialyze the solution for 48h and vacuum freeze-dry it.

[0058] (2) Glycosylation modification of casein-caffeic acid covalent substance:

[0059] Dissolve casein-caffeic acid covalent powder and glucose in water at a mass ratio of 1:1, adjust the pH to 7.4, and mix thoroughly; freeze-dry the mixed solution, and freeze-dry the powder at a temperature of 60°C and a humidity of 79%. Maillard reaction (24h) was carried out under the condition to obtain casein-caffeic acid-glucose covalent complex.

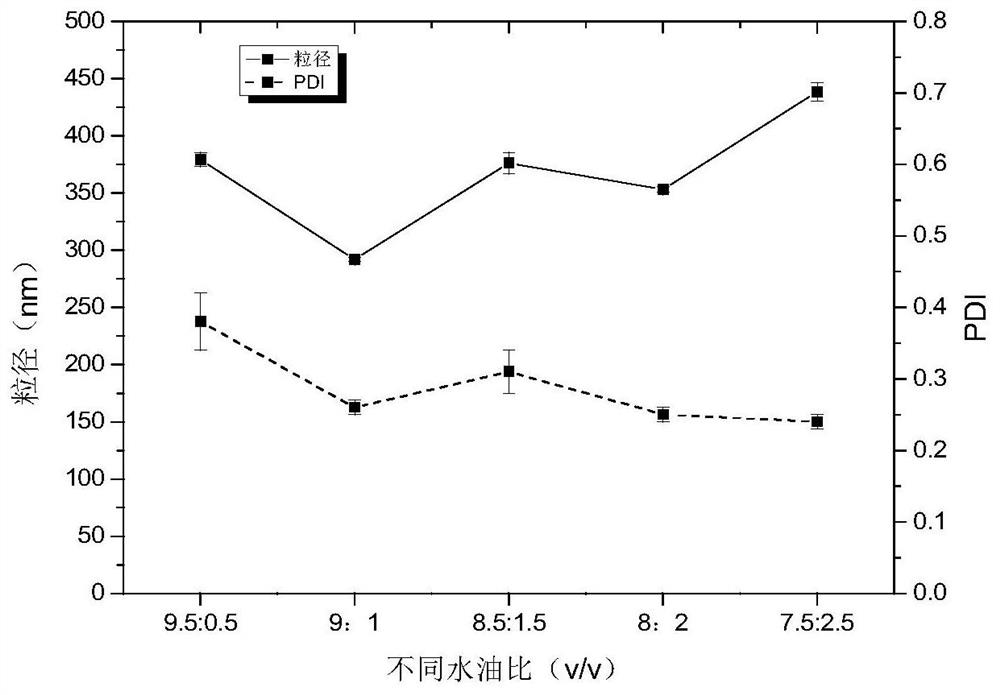

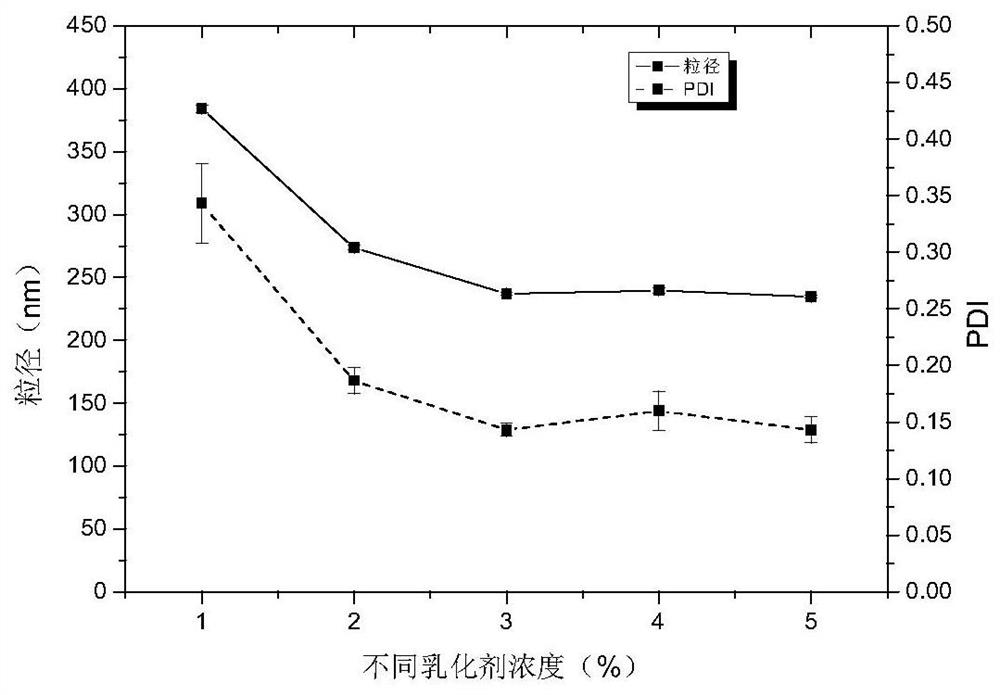

[0060] (3)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com