Nutrient solution for improving goose meat quality and preparation method thereof

A nutrient solution and meat quality technology, applied in the field of nutrient solution, can solve the problems of complicated operation steps and high production cost, and achieve the effects of improving health level and disease resistance, convenient feeding management, and bright feathers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

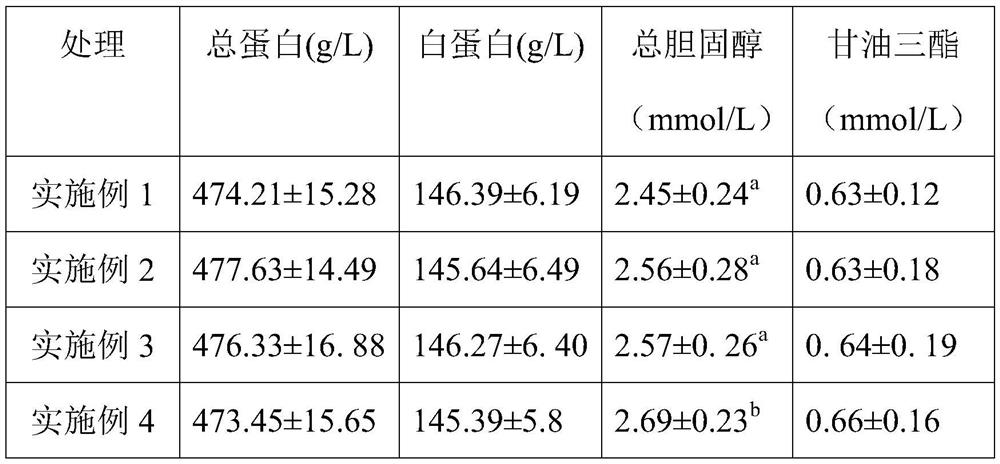

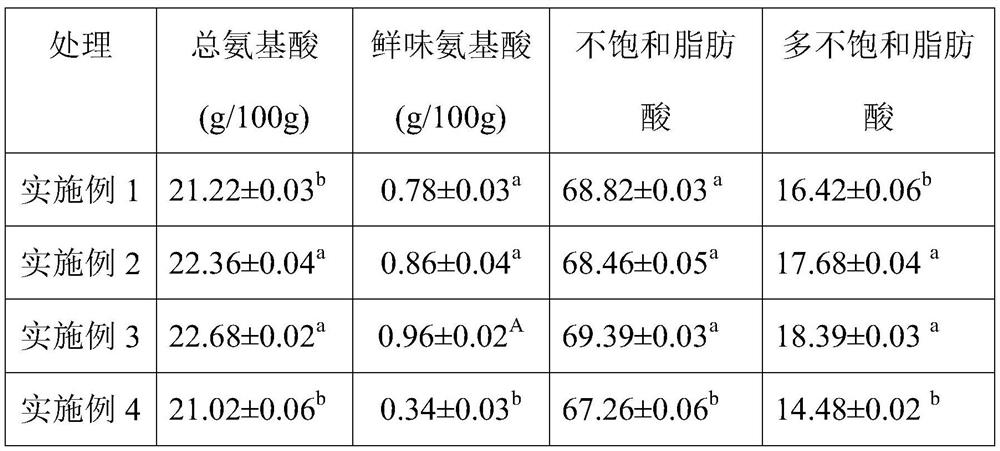

Examples

Embodiment 1

[0029] Raw materials: 46kg of black soldier fly worms, 18kg of live earthworms, 56kg of milk, 0.2kg of protease;

[0030] Auxiliary fermentation agents are: plant lactic acid bacteria 2.3kg, Bacillus coagulans 1.9kg, Bacillus licheniformis 2.2kg, Clostridium butyricum 0.8kg, Candida utilis 3.2kg, Saccharomyces cerevisiae 2.6kg.

[0031] S1), soak black soldier flies fresh worms and live earthworms with fresh milk, then stir and mix with protease to seal them evenly until there is no obvious odor, and install a one-way valve to exhaust during the fermentation process;

[0032] S2), step S1) was fermented with Candida utilis and Saccharomyces cerevisiae for 8 days, stirring once every 1-2 hours, and the temperature was controlled at 27-28°C;

[0033] S3), the mixture obtained in step S2) was mixed with plant lactic acid bacteria, Bacillus coagulans, Clostridium butyricum, and Bacillus licheniformis again in an airtight, mixed and evenly airtightly fermented for 35 days, and the ...

Embodiment 2

[0037] Raw materials: 56kg of black soldier fly worms, 8kg of live earthworms, 0.3kg of protease;

[0038] The auxiliary fermentation agent is: plant lactic acid bacteria 2.9kg, Bacillus coagulans 2.9kg, Bacillus licheniformis 2.2kg, Clostridium butyricum 1.8kg, Candida utilis 3.9kg, Saccharomyces cerevisiae 2.9kg.

[0039] S1), soak black soldier flies fresh worms and live earthworms with fresh milk, then stir and mix with protease to evenly seal until no obvious odor (3-6 months), and install a one-way valve to exhaust during the fermentation process;

[0040]S2), ferment S1), Candida utilis, and Saccharomyces cerevisiae for 12 days, stir once every 2 hours, and control the temperature at 25-26°C;

[0041] S3), mixing the mixture obtained in step S2) again with plant lactic acid bacteria, Bacillus coagulans, Clostridium butyricum, and Bacillus licheniformis, mixing and evenly sealing and fermenting for 35 days, and controlling the temperature at 25-26°C;

[0042] S4), filte...

Embodiment 3

[0045] Raw materials: 26kg of black soldier fly worms, 38kg of live earthworms, 0.4kg of protease;

[0046] Auxiliary fermentation agents are: plant lactic acid bacteria 4.2kg, Bacillus coagulans 1.8kg, Bacillus licheniformis 1.6kg, Clostridium butyricum 1.0kg, Candida utilis 3.4kg, Saccharomyces cerevisiae 3.9kg.

[0047] S1), soak black soldier flies fresh worms and live earthworms with fresh milk, then stir and mix with protease to evenly seal until no obvious odor (3-6 months), and install a one-way valve to exhaust during the fermentation process;

[0048] S2), ferment S1) with Candida utilis and Saccharomyces cerevisiae for 10 days, stir once every 1-2 hours, and control the temperature at 26-28°C;

[0049] S3), the mixture obtained in step S2) is mixed again with plant lactic acid bacteria, Bacillus coagulans, Clostridium butyricum, and Bacillus licheniformis, mixed and evenly sealed and fermented for more than 35 days, and the temperature is controlled at 26-28°C;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com