High-pressure processing method of prepared rehmannia root

A Rehmannia glutinosa, high-pressure technology is applied in the directions of medical preparations, pharmaceutical formulations, and plant raw materials containing active ingredients, which can solve the problems of loss of active ingredients and long processing time of Rehmannia glutinosa, and achieve the effect of ensuring product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

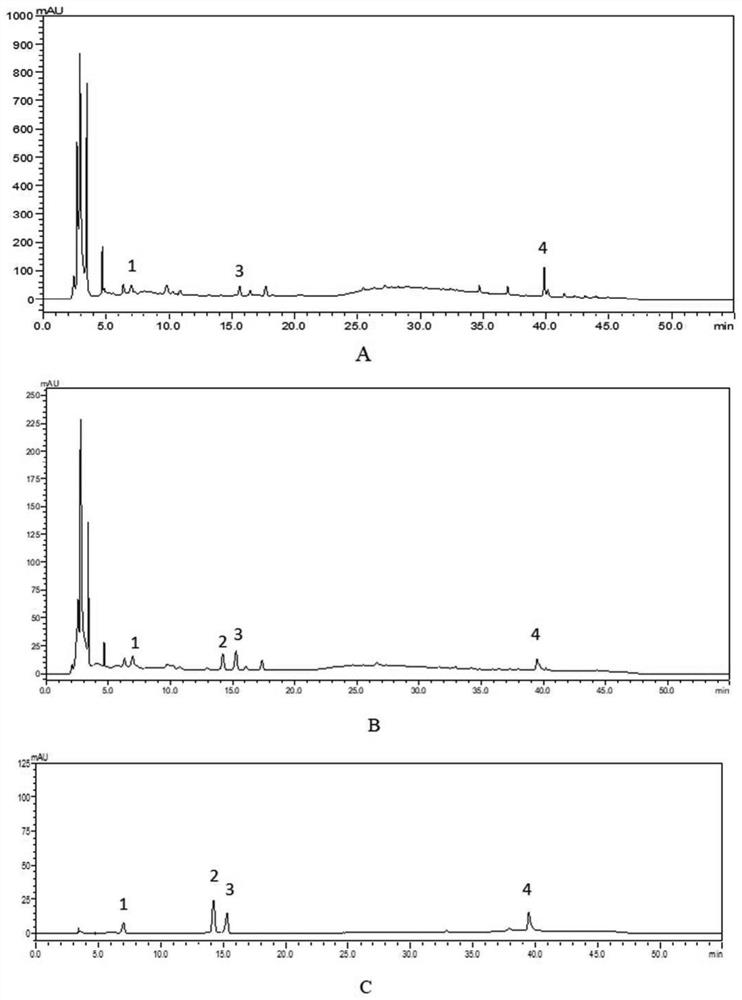

[0015] Embodiment 1 chromatographic condition investigation

[0016] 1. Preparation of the test solution

[0017] Weigh 0.1g of rehmannia glutinosa powder, weigh it accurately, add 25mL of 50% methanol, weigh, heat to reflux for 30 minutes, let cool to room temperature, use 50% methanol to make up the lost weight, and filter through a 0.22μm microporous membrane.

[0018] 2. Preparation of reference solution

[0019] Accurately weigh 4.44, 4.40, 6.02, and 3.49 mg of catalpol, 5-HMF, rehmandin D, and verbascoside in 10 ml volumetric flasks, and dilute to the volume with methanol water (50:50, v / v) ultrapure water. Scale line, sonicate to dissolve completely, and prepare mixed reference substance solutions with concentrations of 0.444, 0.44, 0.602, and 0.349 mg / ml, respectively.

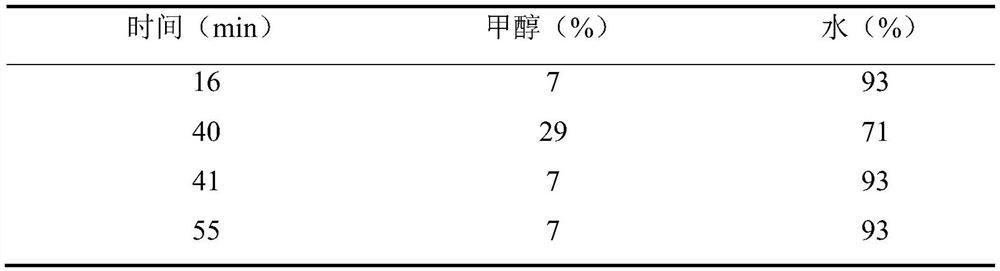

[0020] 3. Chromatographic conditions

[0021] Methanol-water gradient elution (the method is shown in Table 1 below); the flow rate is 1.0 mL / min; the detection wavelength is 210 nm; the column temp...

Embodiment 2

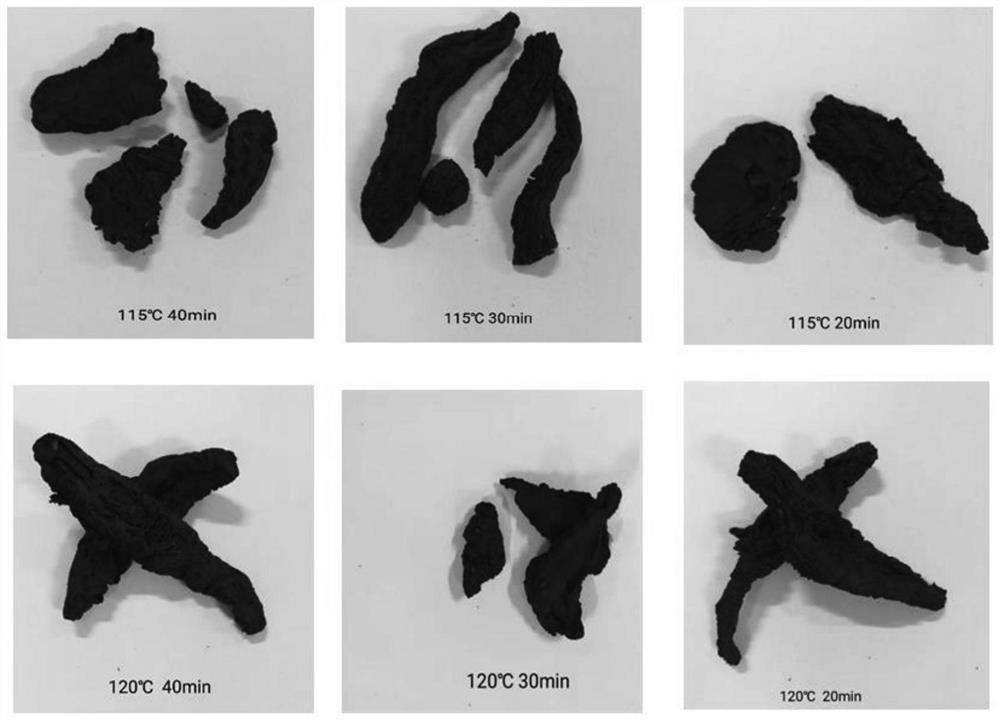

[0041] Embodiment 2 high pressure steaming method twice

[0042] Take raw rehmannia glutinosa, put it in a pressure cooker, set the steaming temperature to 120°C, steam for 10 minutes first, then add 40% water to soak for 4 hours, steam again for 10, 20, 30, and 40 minutes respectively, and the steaming is completed. Take out, slice, dry, measure the content of above-mentioned 4 compositions by the method for embodiment 1. The results are shown in Table 4.

[0043] Table 4:

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com