Continuous SiC fiber-reinforced refractory metal-based composite material based on nano-multilayer structure and preparation method and application of continuous SiC fiber-reinforced refractory metal-based composite material

A refractory metal, nano-multilayer technology, applied in metal material coating process, coating, ion implantation plating, etc., can solve problems such as excessive molding temperature, interface reaction SiC fiber reinforcement performance degradation, etc., to achieve release Residual stress, abundant optional types, and the effect of suppressing interface reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

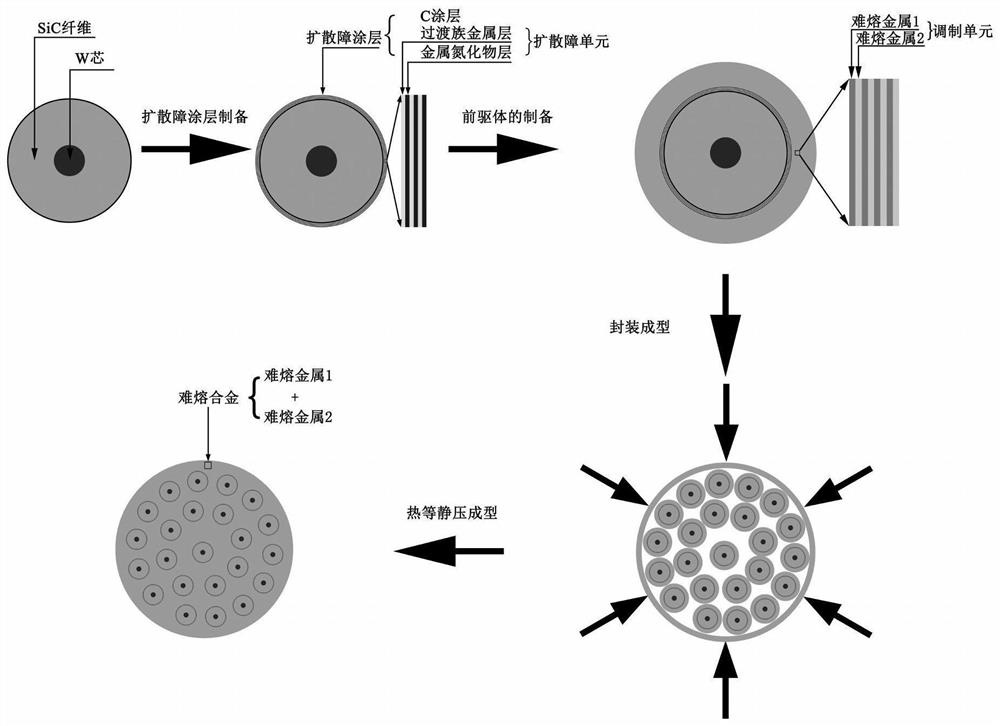

[0034] The present invention provides a method for preparing a continuous SiC fiber-reinforced refractory metal matrix composite material based on a nano-multilayer structure described in the above technical solution, comprising the following steps:

[0035] (1) Using a transition metal target, the first magnetron sputtering is carried out on the surface of a continuous SiC fiber with a carbon coating under an inert gas to form a transition metal layer;

[0036] (2) Using a transition metal target, under nitrogen-inert mixed gas, performing second magnetron sputtering on the surface of the transition metal layer to form a transition metal nitride layer to obtain a diffusion barrier unit;

[0037] (3) repeating the preparation operation of the transition metal layer and the transition metal nitride layer on the surface of the diffusion barrier unit to obtain a diffusion barrier coating; the number of repetitions is ≥ 0 times;

[0038] (4) Under an inert gas, using refractory me...

Embodiment 1

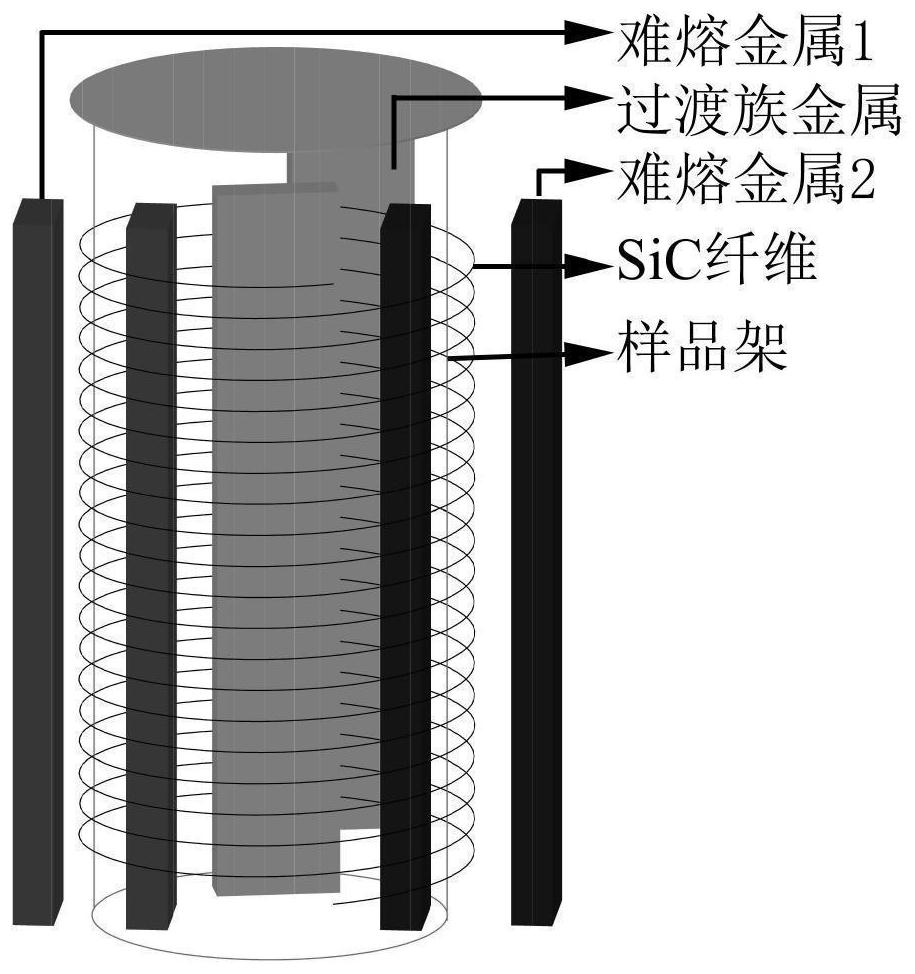

[0068] (1) According to figure 1 The multi-magnetron sputtering device shown and figure 2 The preparation process shown prepares continuous SiC fiber-reinforced refractory metal matrix composites based on nano-multilayer structure, and the specific steps are as follows:

[0069] Fix the continuous SiC fiber with carbon coating on the rectangular sample holder, keep the distance between single fibers at 0.2 mm, and put it into the sample chamber of the multi-target magnetron sputtering equipment; put the Ti target, Nb refractory target and The W refractory targets were respectively placed in the multi-target magnetron sputtering equipment, and the distance between each target and the sample was kept at 10 cm.

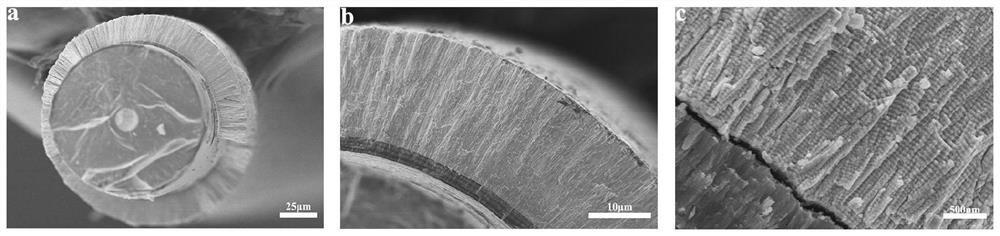

[0070] (2) Vacuum the multi-magnetron sputtering equipment until the background vacuum is lower than 8×10 -4 Pa, the rotation speed of the sample is 50r / h, argon gas is passed through, and the continuous SiC fiber with carbon coating on the surface is sputtered and cl...

Embodiment 2

[0077] A continuous SiC fiber-reinforced refractory metal matrix composite based on a nano-multilayer structure was prepared according to the method of Example 1, the difference from Example 1 is that:

[0078] In step (6), the deposition current of the refractory metal W is 1.5A, the deposition time is 320 min, and the thickness of the composite Nb / W refractory metal layer is 24 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com