Composite diaphragm for reducing energy consumption of hydrogen production by alkaline electrolyzed water

A technology of composite diaphragm and electrolyzed water, which is applied in the direction of diaphragm, electrolytic components, electrolytic process, etc., can solve the problems of low efficiency and high energy consumption, achieve the effects of reducing cost, improving electrical conductivity and gas barrier performance, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

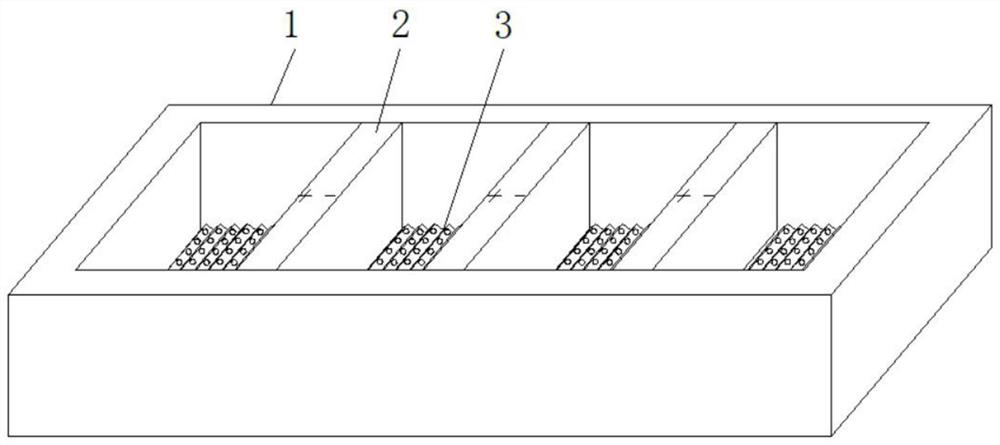

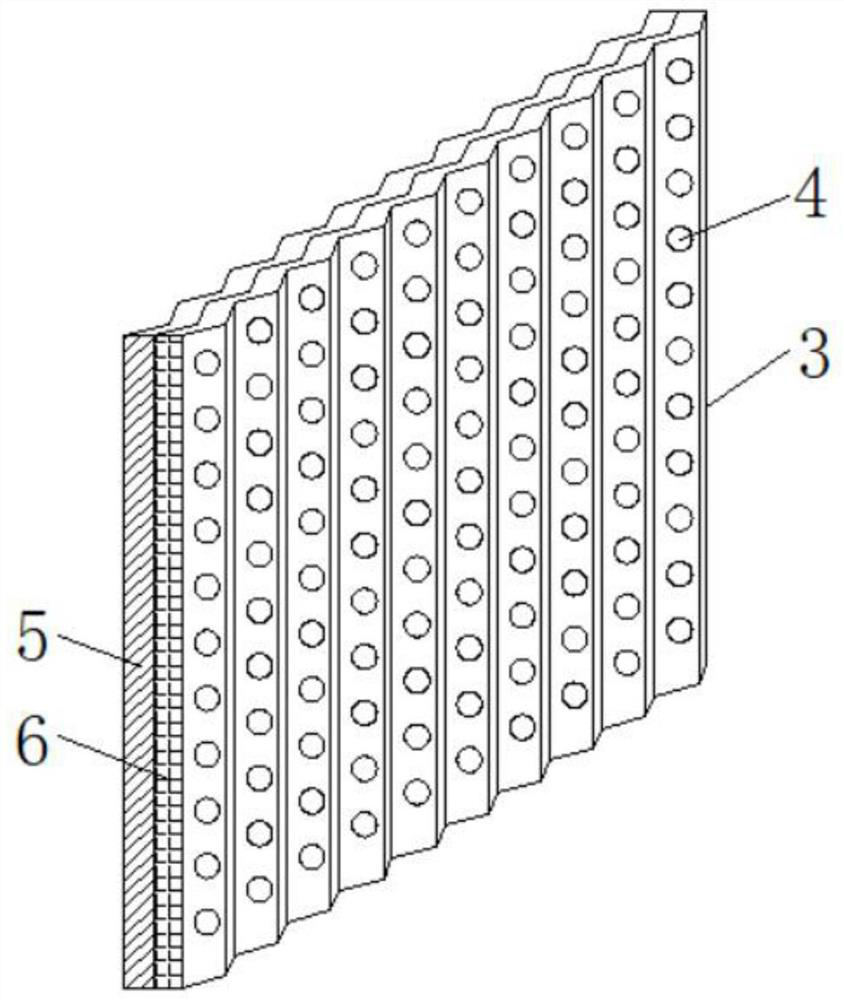

[0033] A composite diaphragm for reducing the energy consumption of alkaline electrolyzed water for hydrogen production, comprising a water electrolyzer 1 and a composite diaphragm 3, the interior of the water electrolyzer 1 is provided with three electrodes 2, and the inner bottom of the water electrolyzer 1 is provided with a composite diaphragm 3, The surface of the composite diaphragm 3 is provided with several through holes 4, and the inner material of the composite diaphragm 3 is respectively provided with an organic layer 5 and an inorganic layer 6, and the raw materials of the composite diaphragm 3 include fluorocarbon compounds and metal oxide particles, wherein the organic part is made of polymer Tetrafluoroethylene, the inorganic part usually uses TiO with good chemical stability and hydrophilic 2 , ZrO 2 , Y2O 3 and other metal oxide particles.

[0034] A composite diaphragm for reducing the energy consumption of hydrogen production by alkaline electrolysis of wa...

Embodiment 2

[0058] A composite diaphragm for reducing the energy consumption of alkaline electrolyzed water for hydrogen production, comprising a water electrolyzer 1 and a composite diaphragm 3, the interior of the water electrolyzer 1 is provided with three electrodes 2, and the inner bottom of the water electrolyzer 1 is provided with a composite diaphragm 3, The surface of the composite diaphragm 3 is provided with several through holes 4, and the inner material of the composite diaphragm 3 is respectively provided with an organic layer 5 and an inorganic layer 6, and the raw materials of the composite diaphragm 3 include fluorocarbon compounds and metal oxide particles, wherein the organic part is made of polymer For tetrafluoroethylene, the inorganic part usually adopts metal oxide particles such as TiO2, ZrO2, Y2O3 and the like with good chemical stability and hydrophilicity.

[0059] A composite diaphragm for reducing the energy consumption of hydrogen production by alkaline electr...

Embodiment 3

[0082] A composite diaphragm for reducing the energy consumption of alkaline electrolyzed water for hydrogen production, comprising a water electrolyzer 1 and a composite diaphragm 3, the interior of the water electrolyzer 1 is provided with three electrodes 2, and the inner bottom of the water electrolyzer 1 is provided with a composite diaphragm 3, The surface of the composite diaphragm 3 is provided with several through holes 4, and the inner material of the composite diaphragm 3 is respectively provided with an organic layer 5 and an inorganic layer 6, and the raw materials of the composite diaphragm 3 include fluorocarbon compounds and metal oxide particles, wherein the organic part is made of polymer For tetrafluoroethylene, the inorganic part usually adopts metal oxide particles such as TiO2, ZrO2, Y2O3 and the like with good chemical stability and hydrophilicity.

[0083] A composite diaphragm for reducing the energy consumption of hydrogen production by alkaline electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com