Two-step packaging method of flexible piezoelectric fiber composite material

A fiber composite material, piezoelectric fiber composite technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, components of piezoelectric devices or electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive Devices and other directions can solve the problems of increased difficulty in manual alignment, less difficulty in alignment, and easy sliding, and achieve the effect of reducing the difficulty of electrode alignment, efficient and stable packaging, and easy and tight combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

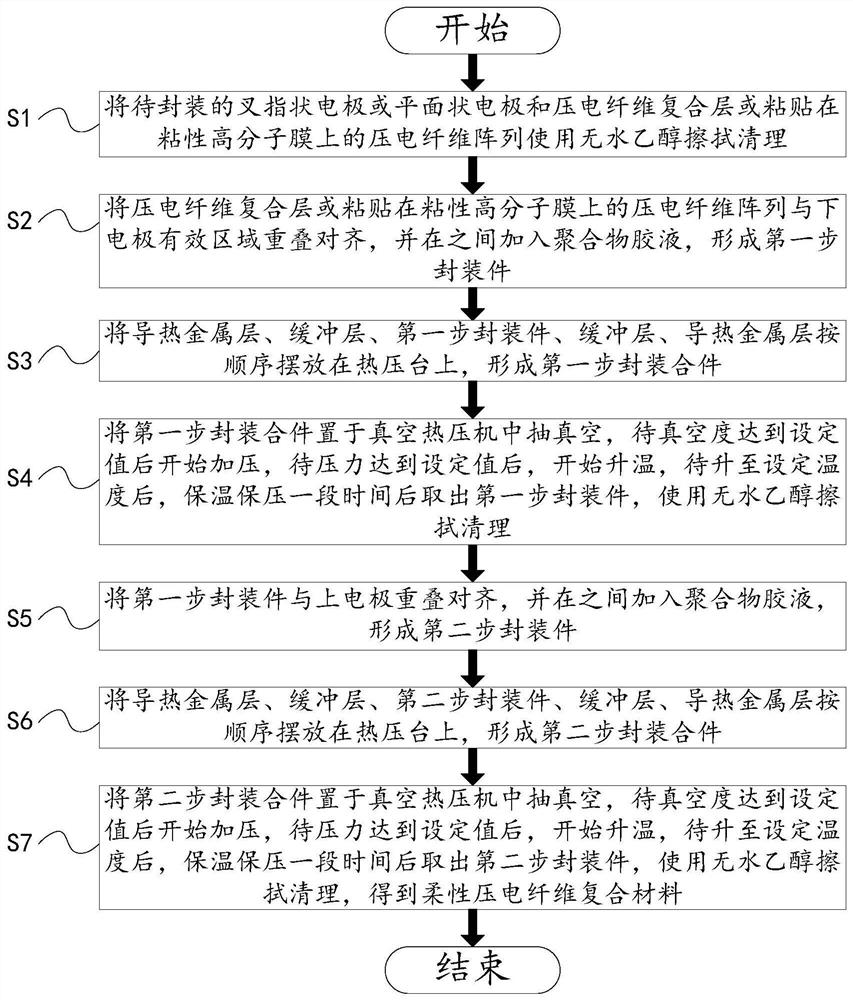

[0032] see Figure 1-Figure 7 , the present invention provides a technical solution: a two-step packaging method for flexible piezoelectric fiber composite materials, such as figure 1 shown, including the following steps:

[0033] S1. Wipe and clean the interdigitated electrode or planar electrode to be packaged and the piezoelectric fiber composite layer or the piezoelectric fiber array pasted on the viscous polymer film with absolute ethanol;

[0034] S2. Overlap and align the piezoelectric fiber composite layer or the piezoelectric fiber array pasted on the viscous polymer film with the effective area of the lower electrode, and add polymer glue between them to form the first step package;

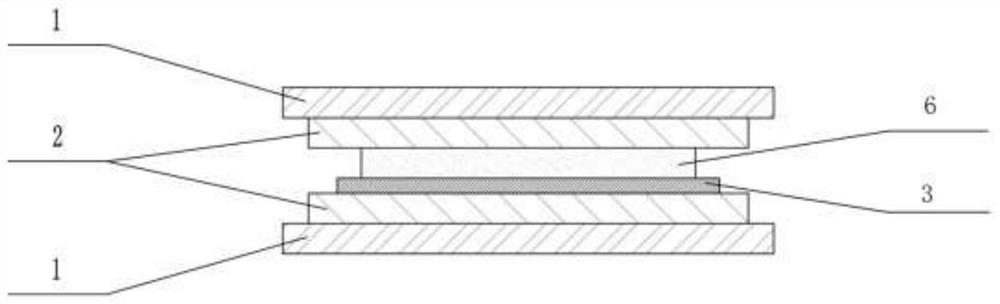

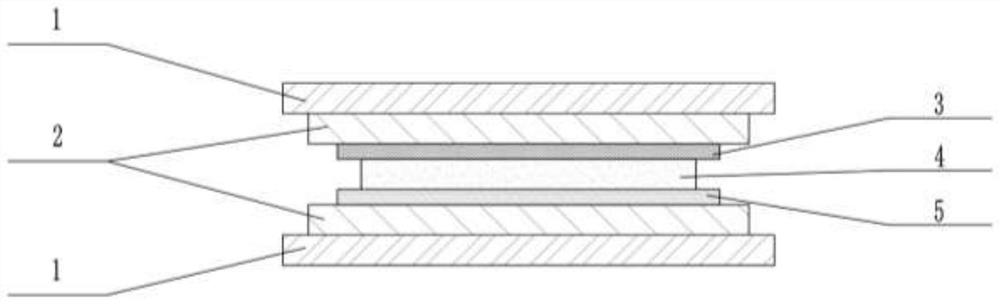

[0035] S3. Place the heat-conducting metal layer, the buffer layer, the first-step package, the buffer layer, and the heat-conducting metal layer on the heat-pressing table in order to form the first-step package;

[0036] S4. Place the first step of packaging assembly in a vacuum h...

Embodiment 2

[0061] Use the two-step packaging method to package the planar electrode type flexible piezoelectric fiber composite material with a size of 10.5mm*8mm*2mm, and test its output voltage signal. The specific process of the two-step packaging is as follows:

[0062] 1. First, the piezoelectric fiber composite layer is prepared, and the piezoelectric fiber composite layer and the planar electrodes should be wiped and cleaned with absolute ethanol before packaging. The area occupied by the piezoelectric fiber array is 5mm*5mm, the thickness is 0.2mm, the planar electrode is composed of polyimide film and copper plated on the film, and the effective electrode area is 5mm*5mm.

[0063] 2. Use an electronic balance to weigh 10g of epoxy resin, and prepare polymer glue.

[0064] 3. Carry out the first step of encapsulation. After uniformly coating a layer of polymer glue on the inner surface of the lower plane electrode, at the same time, evenly coat the upper surface of the piezoelect...

Embodiment 3

[0073] Use the two-step packaging method to package the interdigitated electrode type flexible piezoelectric fiber composite material with a size of 82mm*42mm*3mm, and test its strain. The specific process of the two-step packaging is as follows:

[0074] 1. First prepare the piezoelectric fiber array pasted on the viscous polymer film. Before packaging, the piezoelectric fiber array and the interdigitated electrodes should be wiped and cleaned with absolute ethanol. Among them, the piezoelectric fiber array occupies an area of 65mm*33mm and a thickness of 0.2mm. The interdigitated electrodes are composed of polyimide film and copper plated on the film. The effective electrode area is 65mm*33mm. The viscous polymer film For UV film.

[0075] 2. Use an electronic balance to weigh 10g of epoxy resin, and prepare polymer glue.

[0076] 3. Carry out the first step of encapsulation. After uniformly coating a layer of polymer glue on the inner surface of the lower interdigitated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com