Lithium ion battery positive electrode material and preparation method and application thereof

A technology for lithium ion batteries and cathode materials, which is applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve problems such as incompatibility and difficulty in optimizing the performance of ternary materials, and achieve simple preparation methods, improved electrical conductivity and chemical stability. Sexuality, the effect of reducing side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

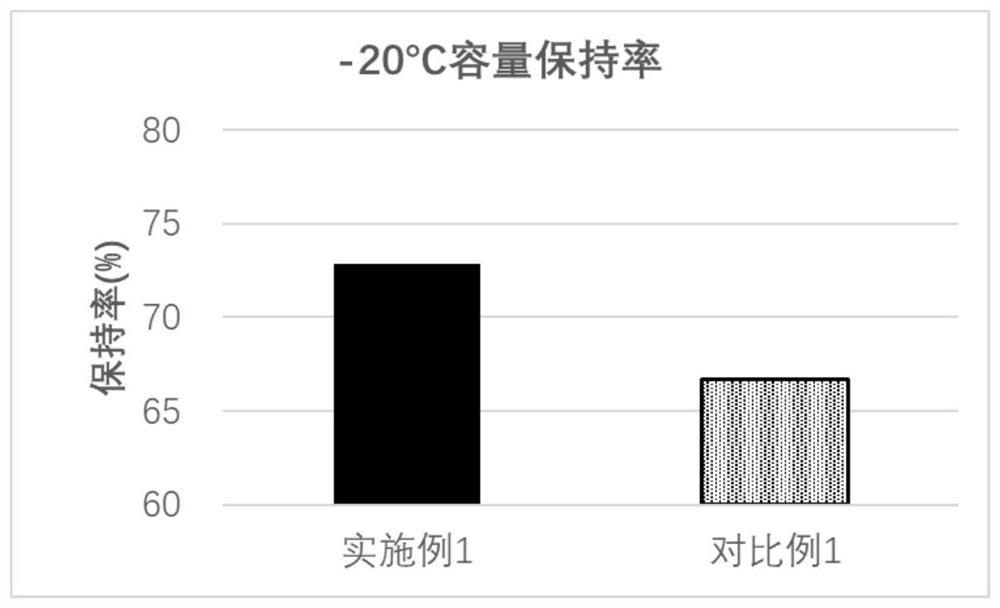

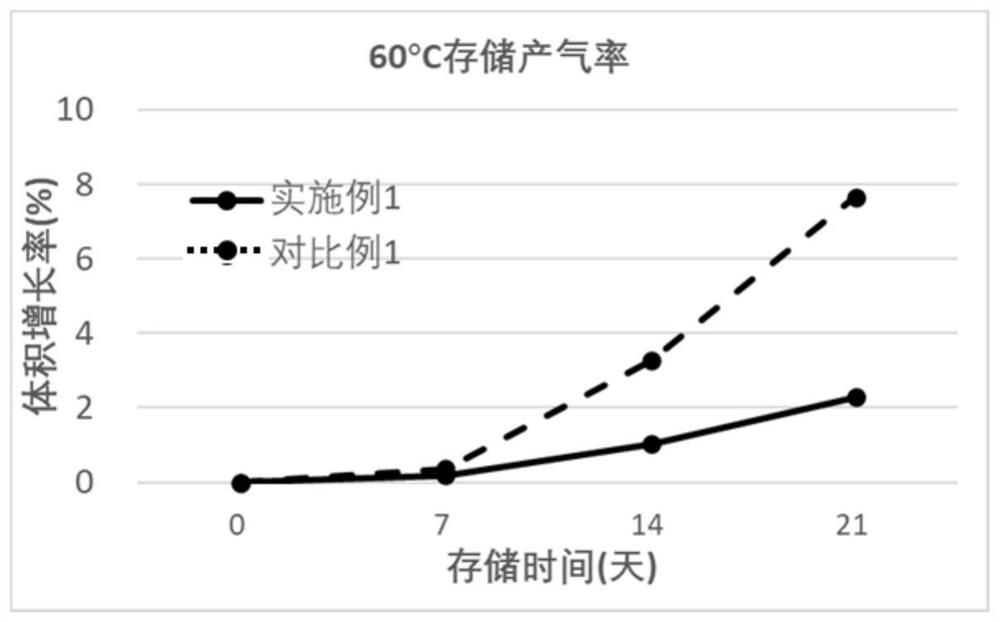

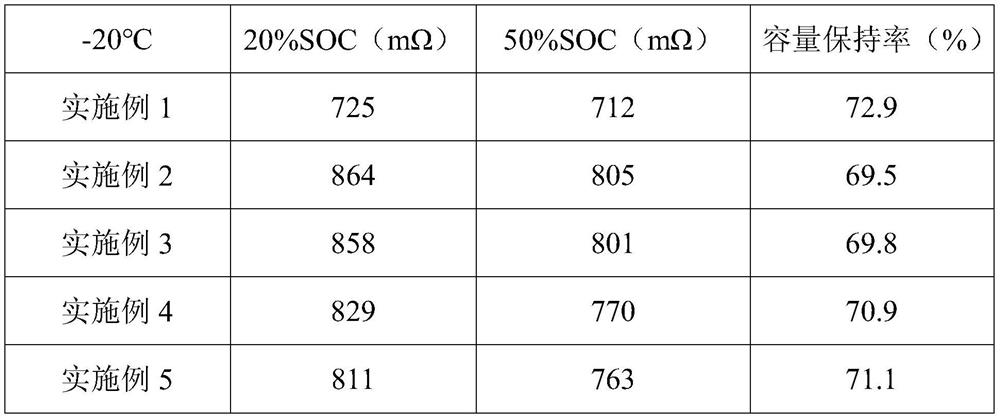

Embodiment 1

[0041] This embodiment provides a method for preparing a positive electrode sheet, the method comprising the following steps:

[0042] (1) Al 2 W 3 o 12 and LiNi 0.64 co 0.09 mn 0.27 o 2 After mixing, it is sintered at 525°C for 20 hours at one time to obtain the positive electrode material of lithium ion battery. The LiNi 0.64 co 0.09 mn 0.27 o 2 It is a secondary ball, the D50 particle size is 11μm, the Al 2 W 3 o 12 and LiNi 0.64 co 0.09 mn 0.27 o 2 The mass ratio is 0.4:99.6;

[0043] (2) Lithium-ion battery positive electrode material, conductive carbon black, conductive carbon tube, polyvinylidene fluoride and nitrogen methyl pyrrolidone mass ratio is 97.5:1:0.5:1:40, conductive carbon black, conductive carbon tube, poly Stirring the vinylidene fluoride and nitrogen methyl pyrrolidone at 500 rpm for 2 hours to obtain a conductive slurry, mixing the obtained conductive slurry with the positive electrode material of the lithium ion battery and stirring at ...

Embodiment 2

[0046] This embodiment provides a method for preparing a positive electrode sheet, the method comprising the following steps:

[0047] (1) Al 2 W 3 o 12 and LiNi 0.5 co 0.3 mn 0.2 o 2 After mixing, it is sintered at 300°C for 40 hours at one time to obtain the positive electrode material of lithium ion battery. The LiNi 0.5 co 0.3 mn 0.2 o 2 For the secondary ball, the D50 particle size is 2μm, the Al 2 W 3 o 12 and LiNi 0.5 co 0.3 mn 0.2 o 2 The mass ratio is 0.01:99.99;

[0048] (2) Lithium-ion battery cathode material, the mass ratio of conductive carbon black, polyvinylidene fluoride and nitrogen methyl pyrrolidone is 90:0.5:0.5:20, after mixing conductive carbon black, polyvinylidene fluoride and nitrogen methyl pyrrolidone Stirring at 500rpm for 2h to obtain a conductive slurry, mixing the obtained conductive slurry with the lithium-ion battery positive electrode material and stirring at 500rpm for 2h to obtain a positive electrode slurry;

[0049] (3) ...

Embodiment 3

[0051] This embodiment provides a method for preparing a positive electrode sheet of a lithium ion battery, the method comprising the following steps:

[0052] (1) Al 2 W 3 o 12 and LiNi 0.8 co 0.1 mn 0.1 o 2 After mixing, sinter at 750°C for 2 hours at one time to obtain the positive electrode material of lithium ion battery. The LiNi 0.8 co 0.1 mn 0.1 o 2 For secondary balls, the D50 particle size is 20μm, the Al 2 W 3 o 12 and LiNi 0.8 co 0.1 mn 0.1 o 2 The mass ratio is 4:96;

[0053] (2) Lithium-ion battery positive electrode material, conductive carbon black, conductive carbon tube, polyvinylidene fluoride and nitrogen methyl pyrrolidone mass ratio is 99:2:1.5:1.5:40, the conductive carbon black, conductive carbon tube, poly After mixing vinylidene fluoride and nitrogen methyl pyrrolidone, stir at 500 rpm for 2 hours to obtain a conductive slurry, mix the obtained conductive slurry with the lithium-ion battery positive electrode material and stir at 500 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com