Nano platinum catalyst taking carbon nano tube as carrier and preparation method of nano platinum catalyst

A technology of carbon nanotubes and nano-platinum, which is applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of low surface loading of Pt catalysts and poor catalytic activity of materials, so as to improve electrical conductivity and chemical stability, Effect of improving dispersion and enhancing overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

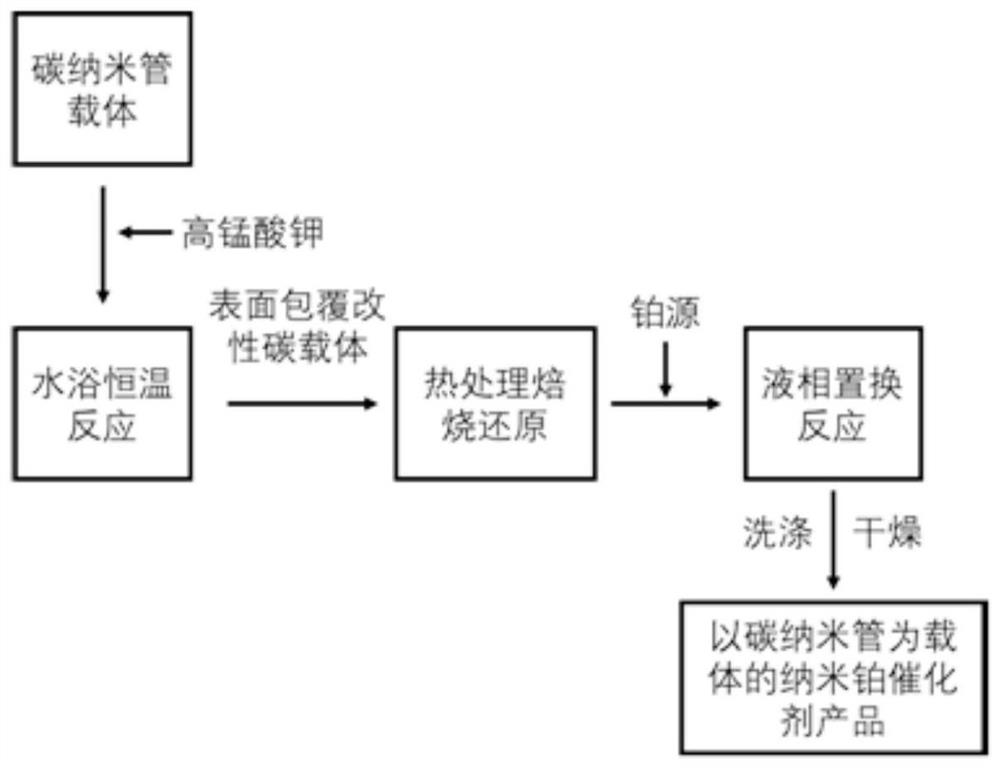

[0034] The preparation steps of the present invention are described in detail as follows:

[0035] The first step is to use carbon nanotubes as the carrier, potassium permanganate as the manganese source, and stir and react at a constant temperature of 60-90°C in an aqueous solution for 1-10 hours, so that a layer of hydrophilic hydrated manganese oxide coating is uniformly grown on the surface of the carbon nanotubes. cladding.

[0036] In the second step, the manganese oxide-coated carbon nanotubes in the first step are heat-treated, and fired at 300-600° C. in an inert / reducing atmosphere to obtain a manganese tetraoxide coating layer with a lower valence state as Functionalized layer on the surface of carbon nanotubes.

[0037] In the third step, the surface functionalized carbon nanotube carrier in the second step is soaked in the platinum-containing aqueous solution, and stirred and reacted at a constant temperature of 50-90°C for 1-5h, so that the high-valent platinum ...

Embodiment 1

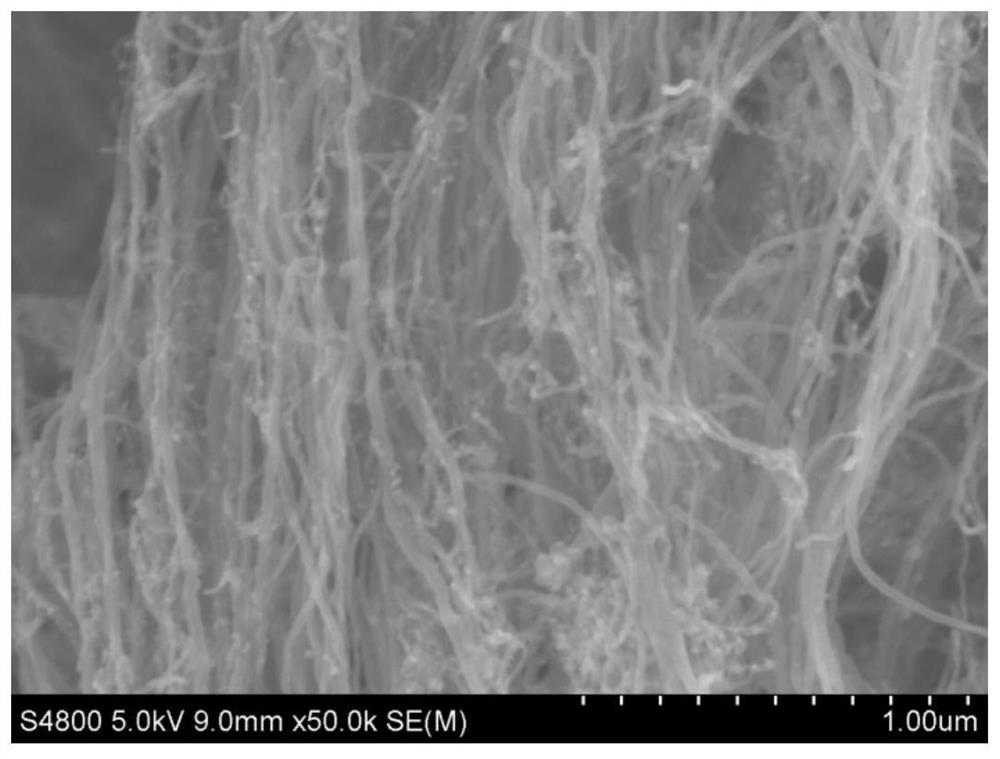

[0041] The preparation method described in the present invention is shown as figure 1 shown. Soak 0.1 g of ordered carbon nanotube array film in 50 mL of water, add 0.1 g of potassium permanganate, fully dissolve, heat and react in a water bath at 60°C for 2.5 h, then take out the film, wash and dry it. The dried precursor membrane was baked at 400°C for 2h in an argon atmosphere, and then soaked in 25mL of aqueous solution of chloroplatinic acid. The theoretical feed ratio of platinum raw materials was set at 20wt%, and the reaction was carried out at a constant temperature of 70°C for 2h. The nano-platinum particles are replaced by trimanganese tetraoxide, deposited on the surface of the carbon nanotube coating layer, and finally the membrane is taken out for washing and drying to obtain the Pt20 / Mn 3 o 4 / VACNT composite catalyst material. figure 2 An electron microscope image of the material is shown in , from which it can be seen that the loading on Mn 3 o 4 The dis...

Embodiment 2

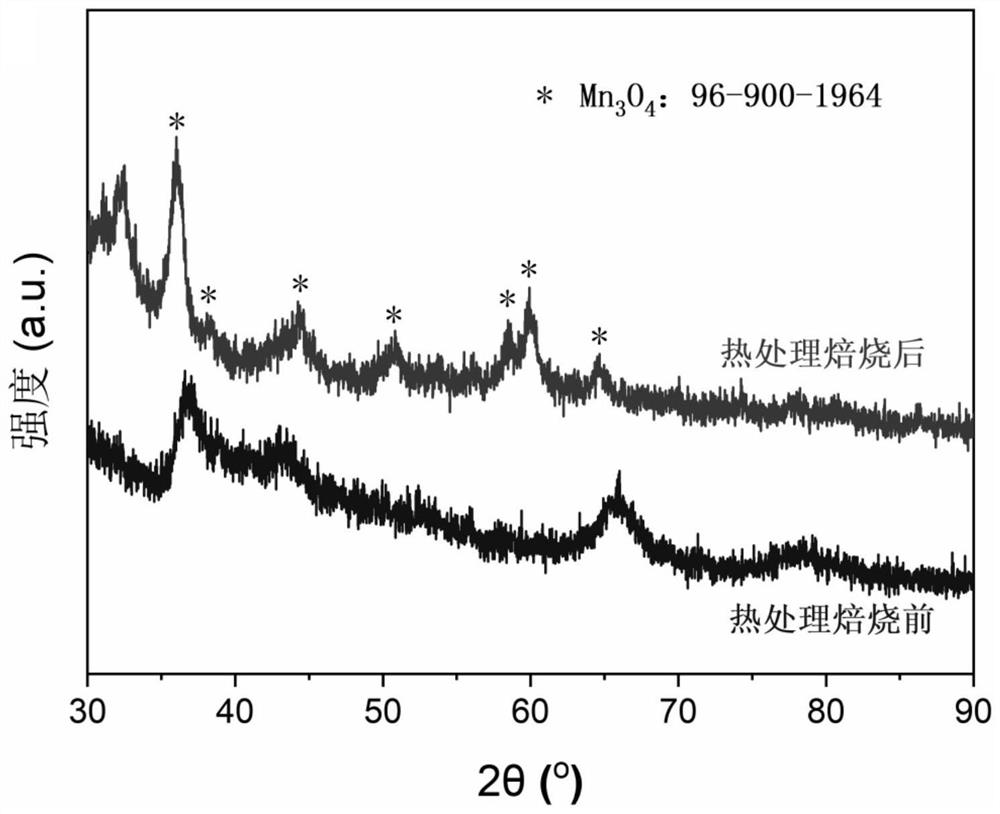

[0043]Soak 1.0 g of commercial multi-walled carbon nanotube powder in 100 mL of water, add 1.0 g of potassium permanganate, fully dissolve, heat and react in a water bath at 90°C for 1 h, then filter with suction, wash and dry. The dried powder was calcined at 300° C. for 6 h under nitrogen atmosphere. Comparison of XRD crystal structure characteristic curves of MWCNT samples with manganese oxide functionalized coating before and after reduction roasting image 3 As shown, it can be seen that the product after reduction and roasting has an obvious crystal phase of Mn3O4. Then, the thermally reduced Mn 3 o 4 / MWCNT composite is soaked in 250mL aqueous solution of chloroplatinic acid, the theoretical feed ratio of platinum raw material is set to 10wt%, and the constant temperature is reacted at 50°C for 5h, so that the nano-platinum particles are replaced by trimanganese tetraoxide and deposited on the carbon nanotube-coated layer surface, and finally the product is taken out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com