Method for separating aluminum and silicon from solid waste coal gangue

A technology of coal gangue and solid-liquid separation, applied in chemical instruments and methods, silicate, silicon oxide and other directions, can solve problems such as mixing, and achieve the effect of increasing ion activity and obvious economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

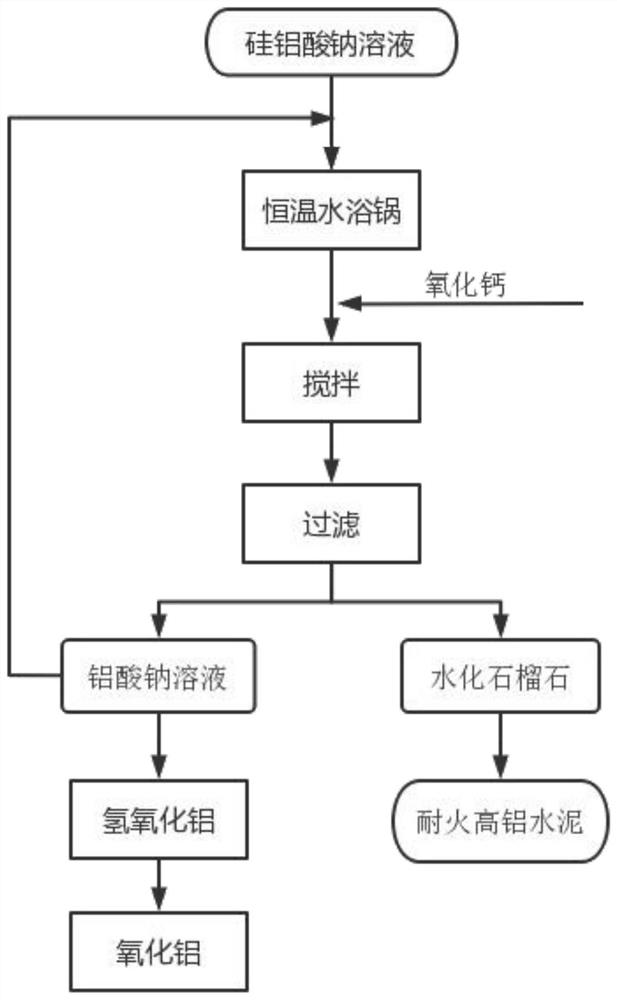

[0037] Such as figure 1 As shown, coal gangue is placed in a stainless steel container through alkali low-temperature activation treatment, dissolved in hot water, separated to obtain a solid phase, separated to obtain a liquid phase after adding a strong acid, and separated after a series of treatments after adding a strong base; The liquid phase is a mixed solution of sodium metaaluminate, sodium silicate, sodium hydroxide, sodium sulfate and potassium sulfate, which is kept in a constant temperature water bath at 90°C, and then 4g / L calcium oxide is added to the sodium aluminosilicate solution, and stirred After 120 minutes and 60 minutes of ultrasonic reaction, the solution is filtered to separate the liquid phase from the solid phase, and the pure aluminum-rich product is obtained by repeated washing to achieve the purpose of desiliconization. Under this process condition, the desiliconization rate can reach more than 90%, and the obtained sodium aluminate solution has hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com