Preparation method of naphthalene water reducer for high fever areas in Middle East

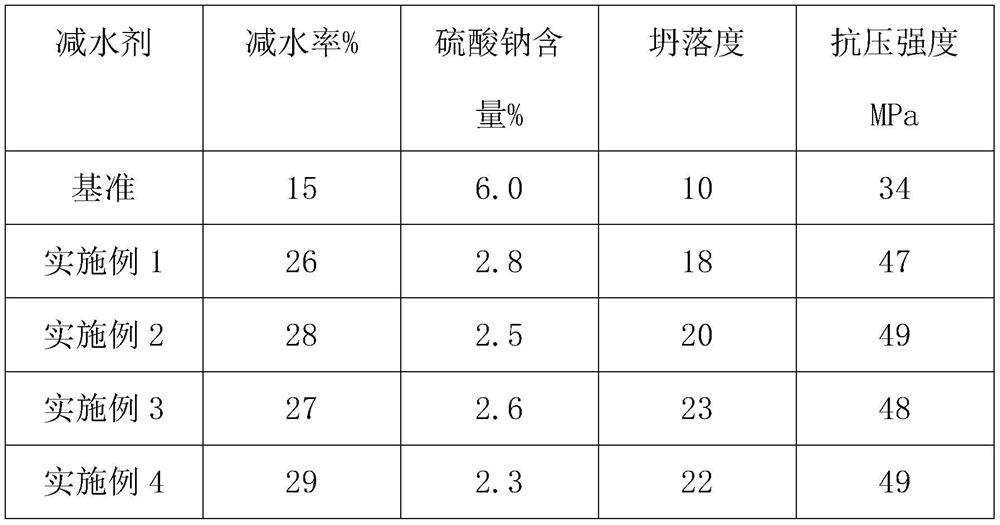

A naphthalene-based water-reducing agent and regional technology, applied in the field of preparation of naphthalene-based water-reducing agents, can solve the problems of rapid loss of concrete slump, poor water-reducing performance of water-reducing agents, and high sodium sulfate content, so as to facilitate construction and use , improve fluidity, prolong the effect of holding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

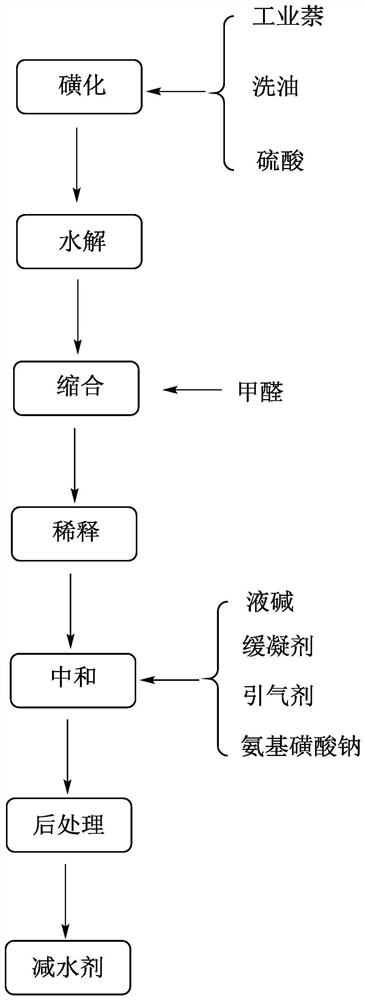

Method used

Image

Examples

Embodiment 1

[0029] A preparation method for a naphthalene-based water reducer used in high-heat areas in the Middle East, comprising the following steps:

[0030] a. Sulfonation: Add 0.8t of industrial naphthalene and 0.4t of washing oil into the reactor, heat up to 100°C, then add 1.04t of concentrated sulfuric acid, heat up to 165°C, and use the oil-water azeotropic process to keep warm for 3 hours to obtain the sulfonated material ;

[0031] b. Hydrolysis: cool down the sulfonated material to 120°C, add water for hydrolysis for 100 minutes, and obtain a hydrolyzate;

[0032] c. Condensation: Add 1.12t of formaldehyde solution with a mass fraction of 37% to the hydrolyzed solution dropwise, finish dropping within 2 hours, control the reaction temperature at 95°C, and react for 90 minutes to obtain a condensation reaction solution;

[0033] d. Add water to dilute: add water to dilute the condensation reaction solution;

[0034] e. Neutralization: Add liquid caustic soda to the diluent ...

Embodiment 2

[0037] A preparation method for a naphthalene-based water reducer used in high-heat areas in the Middle East, comprising the following steps:

[0038] a. Sulfonation: Add 0.8t of industrial naphthalene and 0.24t of washing oil into the reaction kettle, raise the temperature to 130°C, then add 1.52t of concentrated sulfuric acid, raise the temperature to 160°C, and adopt the oil-water azeotropic process to keep warm for 5h to obtain the sulfonated material ;

[0039] b. Hydrolysis: cool down the sulfonated material to 110°C, add water for hydrolysis for 120 minutes, and obtain a hydrolyzate;

[0040] c. Condensation: Add 0.72 t of formaldehyde solution with a mass fraction of 37% to the hydrolyzed solution dropwise, finish dropping within 2 hours, control the reaction temperature at 90° C., and react for 120 minutes to obtain a condensation reaction solution;

[0041] d. Add water to dilute: add water to dilute the condensation reaction solution;

[0042] e. Neutralization: A...

Embodiment 3

[0045] A preparation method for a naphthalene-based water reducer used in high-heat areas in the Middle East, comprising the following steps:

[0046] a. Sulfonation: Add 0.8t of industrial naphthalene and 0.32t of washing oil into the reaction kettle, raise the temperature to 120°C, then add 1.472t of concentrated sulfuric acid, raise the temperature to 162°C, and adopt the oil-water azeotropic process to keep warm for 4h to obtain the sulfonated material ;

[0047] b. Hydrolysis: cool down the sulfonated material to 115°C, add water for hydrolysis for 110 minutes, and obtain a hydrolyzate;

[0048] c. Condensation: Add 0.88 t of formaldehyde solution with a mass fraction of 37% to the hydrolyzed solution dropwise, finish dropping within 2 hours, control the reaction temperature at 90° C., and react for 110 minutes to obtain a condensation reaction solution;

[0049] d. Add water to dilute: add water to dilute the condensation reaction solution;

[0050] e. Neutralization: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com