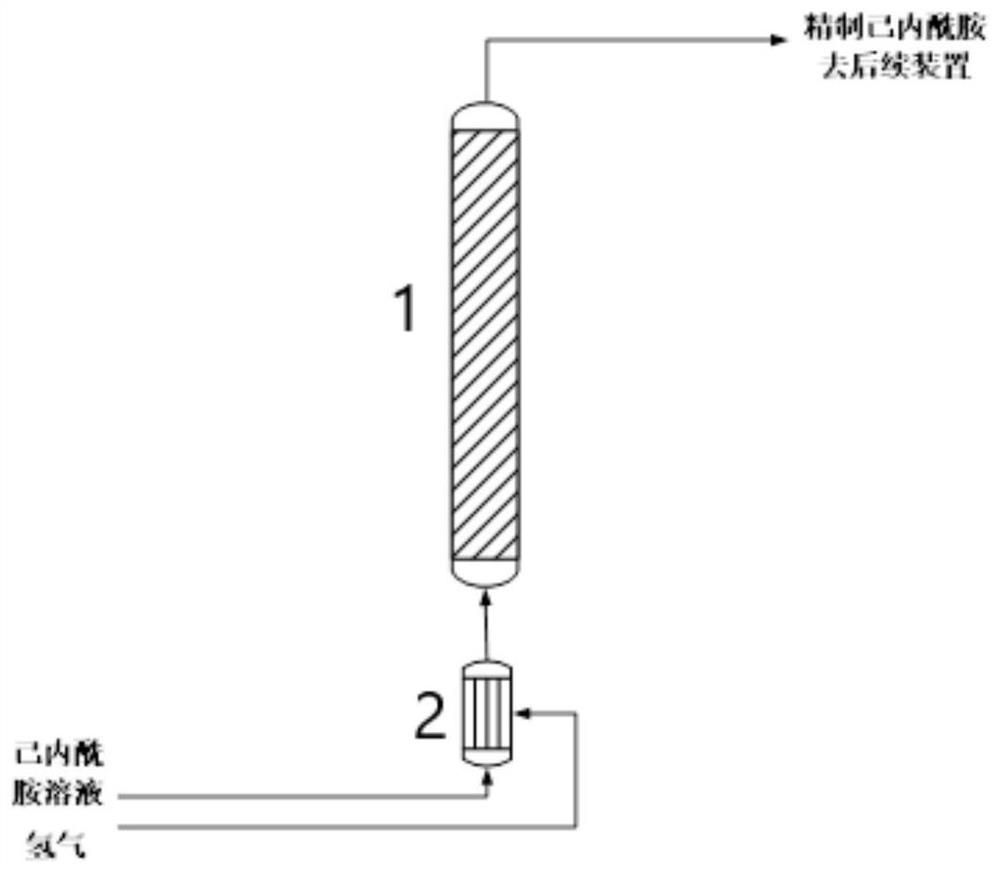

Hydrofining method and device of caprolactam

A technology for caprolactam and hydrofining, which is applied in the field of caprolactam hydrofining, can solve the problem of caprolactam increase, and achieve the effect of high-efficiency hydrogenation, small impact, and continuous process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

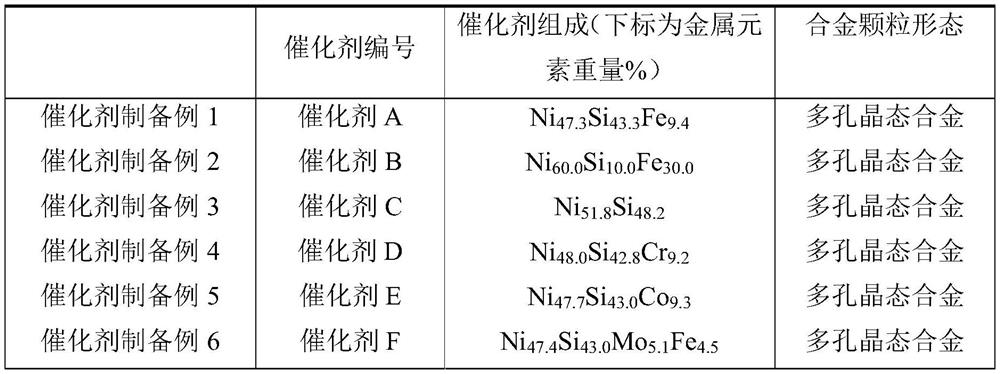

preparation example Construction

[0036] The catalyst preparation method of the present disclosure comprises: cooling the molten mixed metal liquid containing nickel, silicon and optional modifying metal elements at a temperature of 10-40° C., and then pulverizing to obtain coarse alloy particles; The alloy particles are activated sequentially to obtain activated alloy particles; the activated alloy particles are subjected to passivation treatment in an inert atmosphere to obtain the catalyst.

[0037] The optional modifying metal elements contained in the catalyst of the present disclosure can further ensure the stability and hydrogenation activity of the catalyst, and prevent the oxidation of active components such as nickel and silicon in the catalyst.

[0038] The present disclosure has no limitation on the type of reactor for catalyst activation and passivation treatment, which can be a conventional choice in this field, for example, it can be a fixed bed reactor, a fluidized bed reactor or a batch reactor...

preparation example 1

[0065] Add 1.0kg of nickel, 1.3kg of silicon and 0.2kg of iron into a graphite crucible, heat it in a high-frequency furnace until it melts, then pour the molten solution into a stainless steel mold, cool it naturally at 30°C, and crush it to a particle size It is an alloy block of about 3mm, and then accurately weighs 500g of metal alloy particles with an average particle diameter of 3mm, and places it in a quartz glass tube with an inner diameter of 100mm to form a bed of coarse alloy particles. The bottom of the tube flows into the bed of metal alloy particles and then flows out from the top, the bed temperature is 80°C, the activation treatment time is 2h, and the gravimetric space velocity is 2h -1 . After lye activation treatment, wash with deionized water at 60°C until the pH of the solution after washing is 9; then continue to cool under normal pressure in an atmosphere of a mixture of argon and oxygen with an oxygen concentration of 5% by volume The catalyst was obta...

preparation example 2

[0067] The caprolactam hydrotreating catalyst B was carried out using the method of catalyst preparation example 1, the difference being: the raw material composition of catalyst B: nickel content 1.0 kg, silicon content 0.4 kg, iron content 0.5 kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Packing density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com