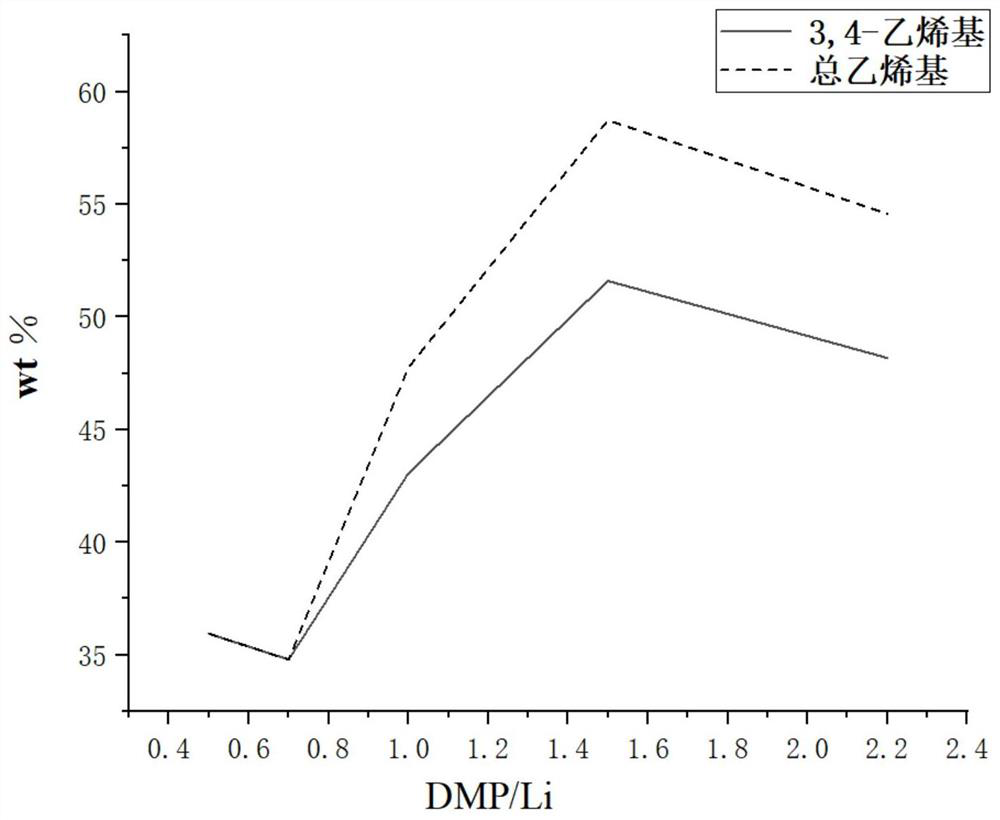

Application of 1, 2-dialkoxy propane as polarity regulator for synthesizing high vinyl aryl ethylene-conjugated diene block copolymer

A technology of dialkoxypropane and high vinyl styrene, which is applied in the field of styrene-butadiene rubber synthesis, can solve the problem of no display ratio relationship, etc., and achieve the effect of outstanding elastic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0034] SBS block copolymers using the preferred polarity regulators of the present invention: SBS block copolymerization in the high temperature range.

[0035] Cyclohexane (2500 mL) was charged to a 5 liter stainless steel stirred reactor under a nitrogen atmosphere. The solvent temperature was stabilized at 50 °C by circulating water inside the reactor and the reactor temperature control was turned off. Then, a first portion of styrene monomer (41 mL) was loaded into the reactor. The styrene feed operation was completed within 0.5 minutes. Thereafter the reactor temperature control was stopped. Thereafter, DMP and n-butyllithium initiator were added to the reactor. The active initiator content and the molar ratio of polar modifier to initiator are shown in the table. Then, a waiting time of 30 minutes was implemented and the feed of butadiene (324 mL) was completed over a period of about 2 minutes. The heat of butadiene polymerization raised the reaction initiation temp...

Embodiment 6~7

[0044] SIS block copolymers using polarity regulators preferred according to the invention: SIS block copolymerization at low polarity regulator concentrations in the high temperature range.

[0045] The first step is to prepare polystyrene hard segment (S). In a jacketed stainless steel polymerization kettle replaced with nitrogen, add 3000 mL of purified cyclohexane, heat up to 50°C with jacketed hot water, and dissolve the first part of benzene 49 mL of ethylene monomer was loaded into the reactor. The styrene feed operation was completed within 0.5 minutes. Thereafter, DMP, n-butyl lithium initiator was added to the reactor. The active initiator content and the molar ratio of polar modifier to initiator are shown in the table. The reaction temperature is 40°C to 70°C, the reaction pressure is 0.2Mp to 0.5Mp, the amount of styrene added is 50% of the total amount of styrene added, and the amount of added butyllithium initiator is determined by the designed average molecul...

Embodiment 8~10

[0053] SIS block copolymers using polarity regulators preferred according to the invention: SIS block copolymerization at high polarity regulator concentrations in the high temperature range.

[0054] (1) load cyclohexane solvent into the reactor; (2) stabilize the solvent to a certain temperature; (3) load styrene monomer and DMP; (4) load n-butyllithium; (5) the first benzene Homopolymerization of ethylene blocks where heat of polymerization increases reactor temperature gradually from styrene charge up to peak temperature; (6) 30 minute waiting time after peak temperature; (7) loading of isoprene monomer And record the reactor temperature; (8) block copolymerization of isoprene, wherein the heat of reaction raises the reactor temperature to the peak temperature, record the peak temperature and the time from the start of isoprene charging to the time when the peak temperature occurs Elapsed time; (9) waiting time; (10) loading second portion of styrene charge; (11) allowing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com